NEW hardcover of the No.1 book on Industrial Design | Prototyping | Engineering | Manufacturing

Project Background

The Maker’s Field Guide has been written as the first and only resource of its kind — demystifying almost every single tool, technology, and process involved in the making, building, or manufacturing of professional quality prototypes for use in design, engineering, product development, special effects, and crowdfunded / Kickstarter projects. Written by acclaimed industrial designer Christopher Armstrong, this book is the by-product of over a decade of practical, hands-on experience honed directly in the field of advanced research & development. Relying on the latest scientific methods in STEM and cutting edge R&D (Research and Development) practices from around the world, it delivers a comprehensive understanding on the use of manual “old-school” tools of the trade, as well as “new-school” state-of-the-art technologies; featuring real-world case studies by top industry professionals in all areas of design, engineering, and filmmaking today.

After launching in late 2018, the book was met with critical acclaim within the industrial design industry, ranking as the #1 Industrial Design book and Top Design Books of All Time by BookAuthority, and was featured in Iron & Air, Urban Workshop, and The Entrepreneur Motivation Podcast.

Now for 2020, we need your help get this momentous book printed as a hardcover! Not only will this hardcover book have a beautifully updated black & gold foil cover design, it will also include 80 new pages of content as an updated & expanded GOLD edition. This is an absolutely essential resource for anyone wanting to achieve professional quality prototype results, with content that’s accessible for everyone from beginner all the way to advanced / professional industry-level.

What is the Maker Movement?

The Maker Movement represents a dramatic shift towards the democratization of design, engineering, education, jobs and manufacturing. Advancements in new technologies such as desktop 3d printing and CNC machining are now putting powerful tools that were once only available to large institutions like NASA in the hands of millions of creators worldwide. This rapid pace of disruption is creating a paradigm shift and playing-field leveler like no other in history, opening up many new opportunities for independent makers and entrepreneurs that were once thought to be unimaginable. As a result, this is leading to what’s known as the small-batch or “lean manufacturing” revolution giving rise to the “maker” and maker culture — the repercussions of which are so monumental, in fact, that it’s often been compared to the countercultural revolution that pervaded the West in the 1960’s.

Put simply — the Maker Movement is a collective group of empowered individuals who are becoming much less dependent on large manufacturers for the production of their goods and services. Add to that an increasing level of interest and investment into corporate R&D (Research and Development) programs that are leveraging the use of new technologies as a way of gaining a competitive advantage in the marketplace. All of these combined factors have placed an emphasis on STEM and engineering educations or skill-sets as the path forward to success in this new era of uncertainty and globalization — with tens of thousands grade-schools worldwide now rushing to build their own Makerspace facilities (now becoming hot commodities) out of both a fear of missing out, and in an attempt to stay out in front of this lighting-fast pace of change in today’s volatile jobs marketplace.

This movement is also responsible for placing less emphasis on formal degrees, and more focus on practical problem-solving capabilities — that can be demonstrated through real life, project-based portfolios instead (or simply put, provability of results as evidenced by real-life examples and / or case studies; no complicated math formulae or academic theory needed). If you’ve seen Kickstarter (or similar crowdfunding platform) campaigns raise millions, or tens of millions of dollars on a relatively simple, scratch-built functional prototype alone — you’ve witnessed the full power of the Maker Movement firsthand.

Updated & Expanded GOLD Edition Sneak Peek

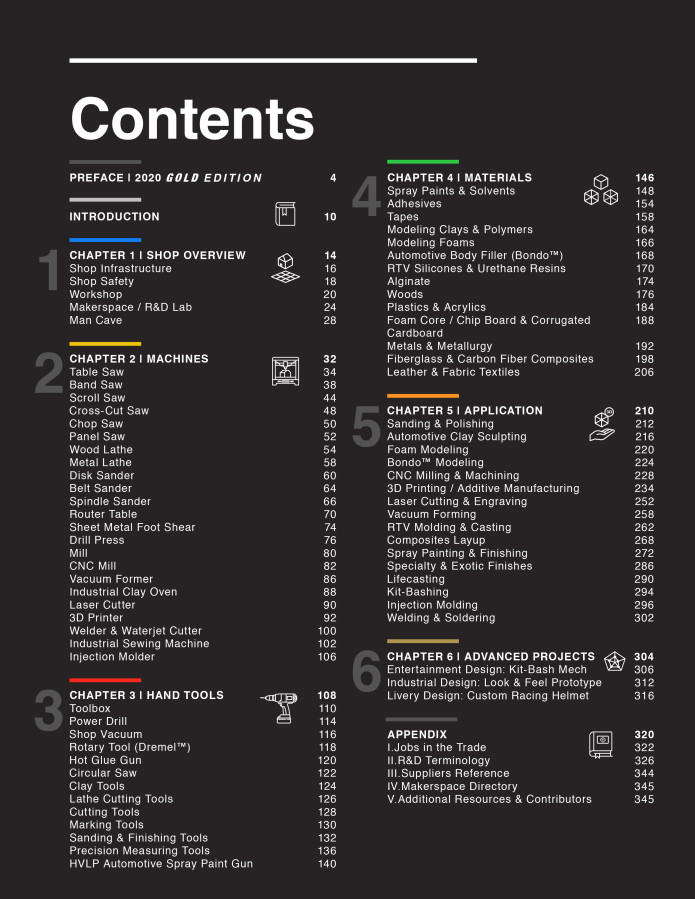

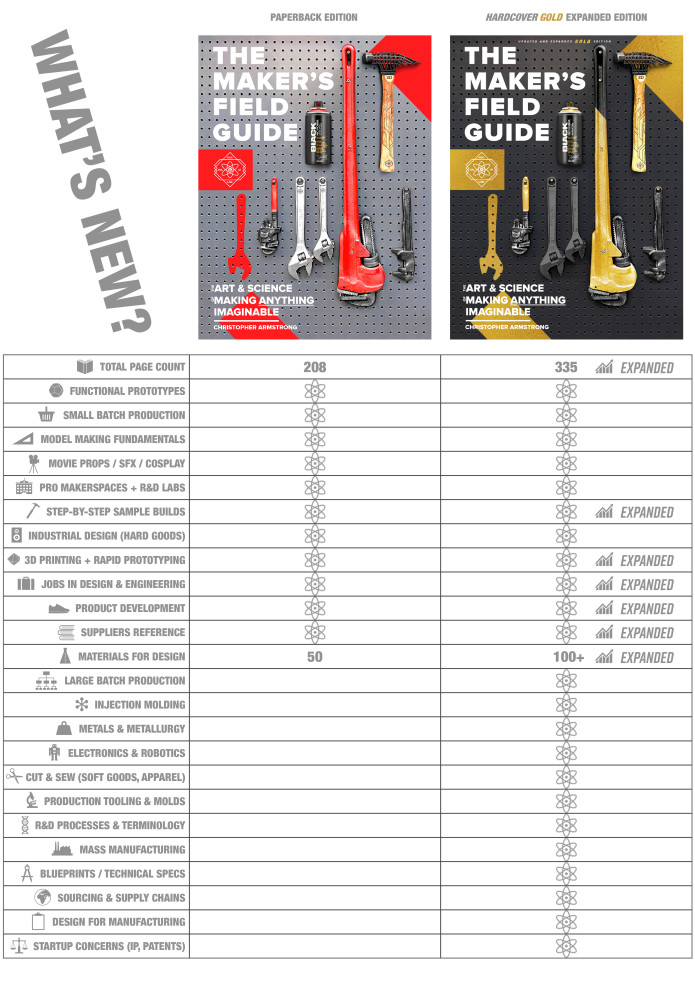

- NEW +115 pages of expanded content (346 pages in total), including content suited for those serious about pursuing a successful career in R&D (research and development) or who are looking to profit from a prototype to launch on Kickstarter. No stone has been left unturned, giving each individual maker or Startup entrepreneur the best chances of success and is easily comparable to tens of thousands of dollars worth of higher education costs in such industrial design, engineering, product development and model making fields:

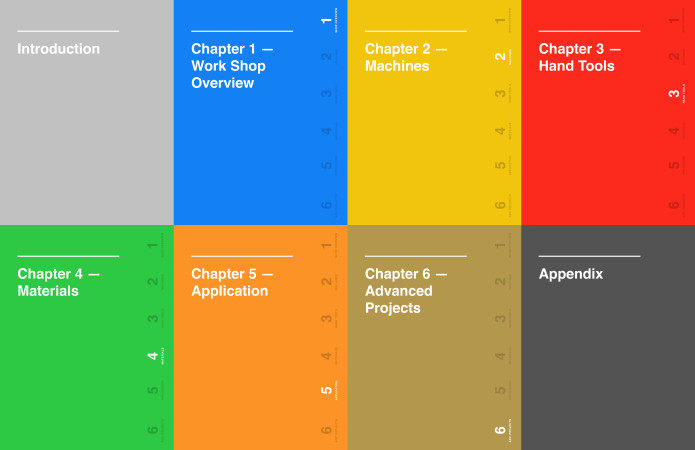

NEW 2020 GOLD expanded Table of Contents

Chapter 02 – Machines (1st ed. paperback content)

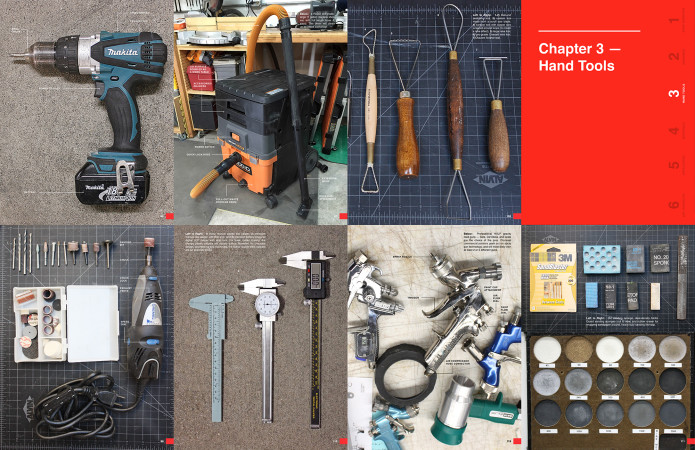

Chapter 03 – Hand Tools (1st ed. paperback content)

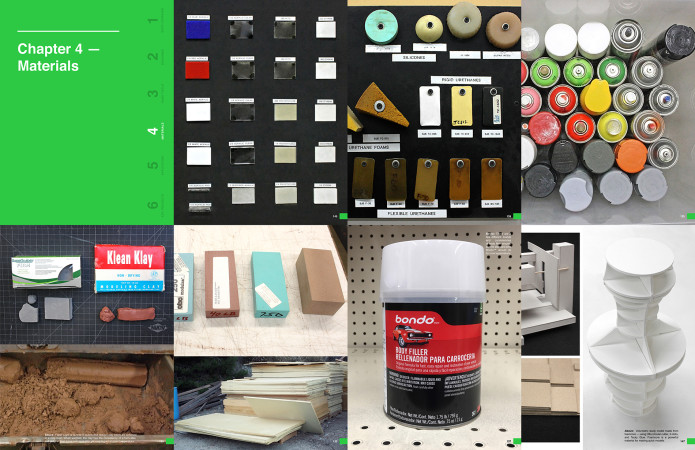

Chapter 04 – Materials (1st ed. paperback content)

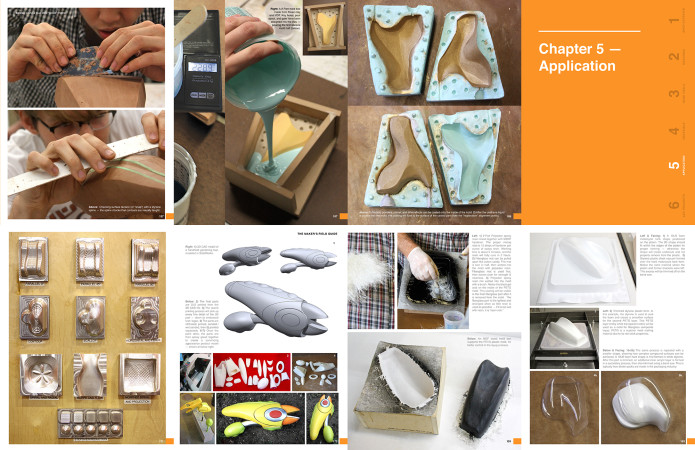

Chapter 05 – Application (1st ed. paperback content)

- Expanded Advanced Projects section, showing step-by-step behind the scenes process of professional project case studies.

- Expanded R&D industry & jobs section, giving a holistic overview on how multidisciplinary teams function to bring successful products to market.

- NEW Index section added, along with a NEW expanded glossary of critical R&D industry terminology.

- NEW added section on mass manufacturing, which peels back the hood on how to bring a conceptual prototype design or invention to market.

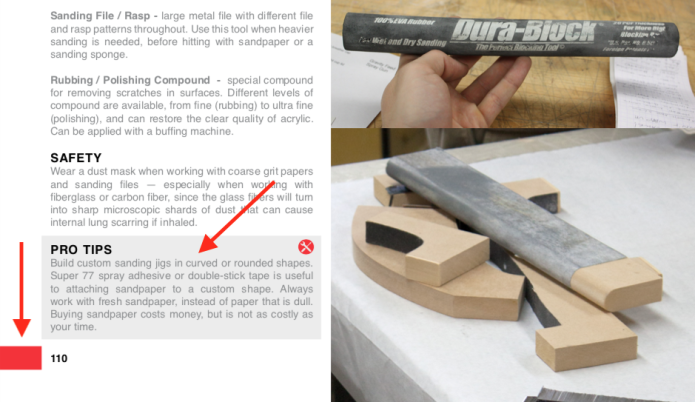

- NEW color coded chapter section tabs and pro tips highlight boxes, to facilitate much easier reference & indexing:

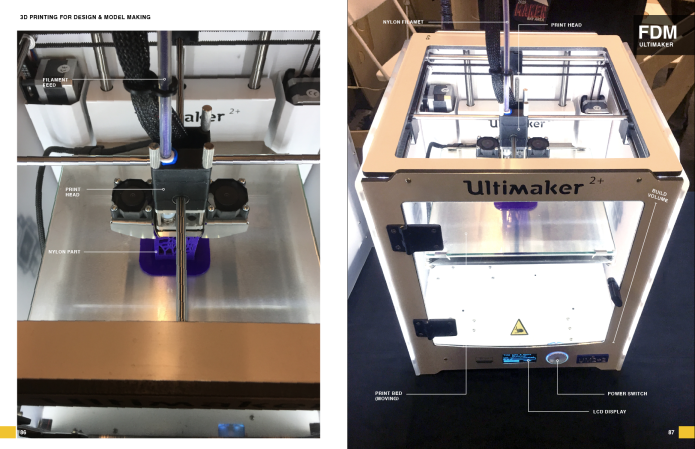

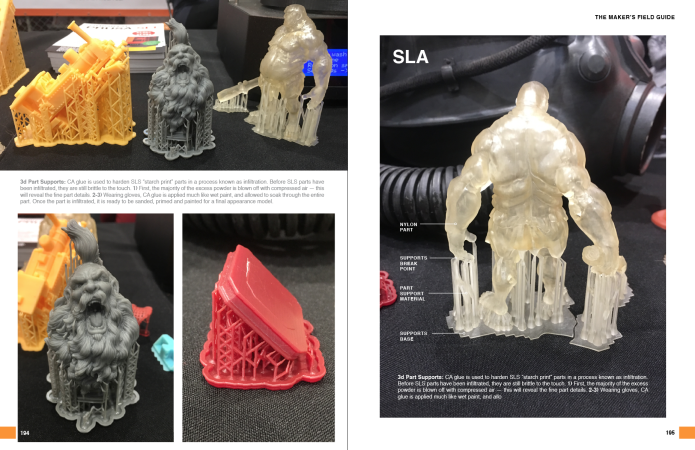

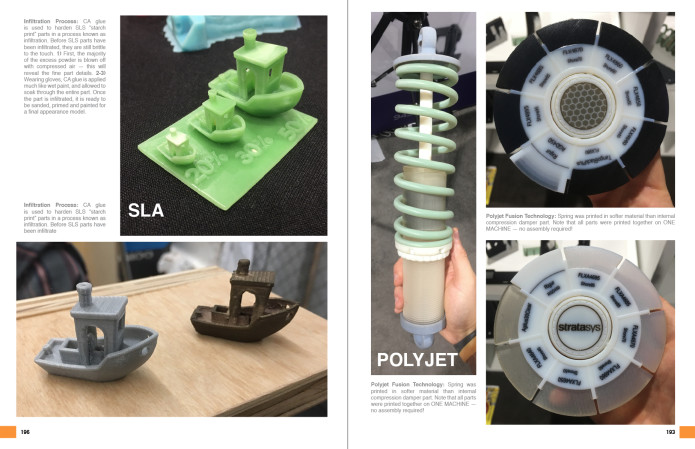

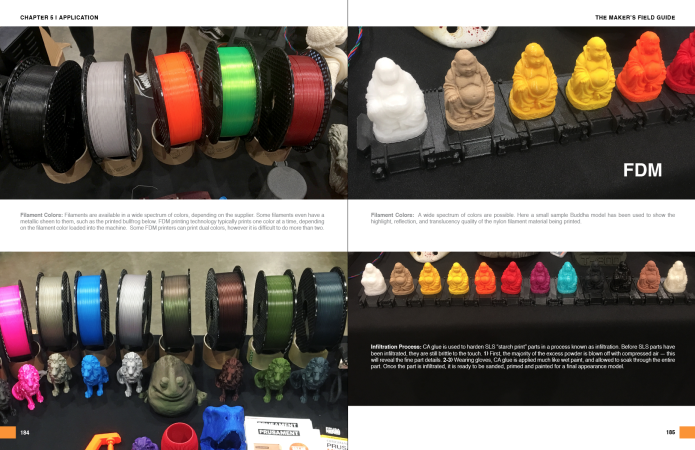

- Expanded and massively updated 3d printing/additive manufacturing section, now featuring 30 new pages covering metal 3d printing, rubber polymers, HP Multijet Fusion, Polyjet and many others. This now makes The Maker’s Field Guide the most comprehensive, exhaustively researched resource covering almost all of the different types of on 3d printing / additive manufacturing anywhere on the planet:

NEW 2020 GOLD expanded content

NEW 2020 GOLD expanded content

NEW 2020 GOLD expanded content

NEW 2020 GOLD expanded content

NEW 2020 GOLD expanded content

- NEW beautiful black/gold foil hardcover format (11″ x 8.5″), for lasting durability & shelf life (just like a quality watch you’d want to pass on down to your grandkids!):

Timing

Make no mistake — while the timing of this campaign is a little “unique” given the COVID-19 situation worldwide, the hardcover edition of this book has been a plan of mine even before the outbreak. Because over 10 million workers have been displaced in the USA alone, this is a time for people who may be struggling to find a source of income. Therefore, the Maker Movement represents is one possible solution of empowering a new wave of entrepreneurs and independent creators to rise up, weather the storm, and to produce new products, innovations or solutions to important problems — in ways that have never been seen before (which, society will be the ultimate beneficiary of).

Optimistically, more than a few groups of open-sourced, decentralized maker communities have made headlines recently, by showcasing to the world their ability to quickly and adaptively contribute innovative solutions to the recent PPE shortages experienced by hospitals. The implications of this type of cross-collaboration on a design & manufacturing front reach far beyond the current situation we are facing. See this fantastic editorial by the NY Times: Coronavirus is Straining Hospitals. Here’s How Innovators Are Helping. | NYT News.

Billionaire Shark Tank investor Mark Cuban is one of the voices of optimism, and has even publicly stated recently that the next 10, 15, or 25 companies that go on to change the world will be starting during these challenging times. In his mind, and in the minds of many other prominent business & investing thought leaders, it is the spirit of entrepreneurial problem solving, innovation, and a dogged persistence that remain the fundamental economic drivers of a nation like America — and will all be key factors in our ability to come out of this pandemic stronger than ever. And, because of the quarantine measures being implemented in many locations, what better opportunity than ever to spend this time reading and learning something new!

Project / Production Status

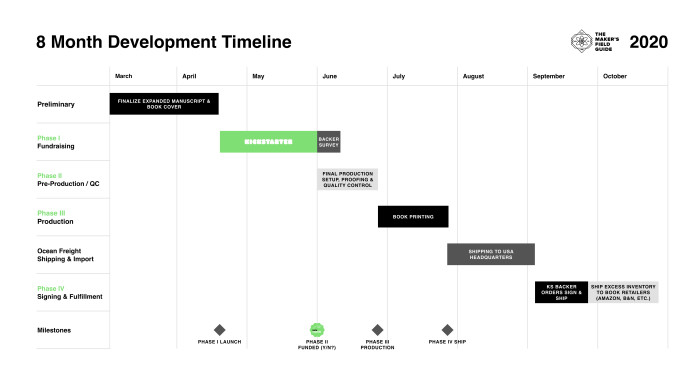

**Current project schedule is a few weeks behind the schedule shown. New expected delivery target for backer shipments is mid to late September 2020.

Manufacturing has already been secured with a production partner in the USA, with the visual proofs already approved, and down payment already submitted to begin setting up the production offset printing plates. Because of the peak summer season, there are a few large jobs which the factory will need to be process before ours can be printed. That said, production is currently in a pre-flight QC pre-check, and is expected to start by mid-August. Once started, printing is estimated to take between 6 to 6 1/2 weeks, then 2 weeks to ship to our warehouse in Southern California.

About Christopher

About Christopher

Christopher Armstrong is an acclaimed industrial designer and product developer, having held senior leadership positions on multiple Advanced R&D / Special Projects teams. His work has been featured in Hypebeast, Digital Trends, Footwear News, TransWorld Motocross (TWMX), Red Bulletin Magazine, AOPA Pilot, Coroflot, RECOIL, Performance BMW, Octane, ImagineFX, and others.

After studying at The Art Center College of Design, he has since spent nearly a decade in the design industry working with over 30+ clients worldwide — everything from small business Startups to Fortune 500 companies — including the NFL, EVS Sports, LIFT Aviation, Hazard 4, Stanley Black & Decker, Sony Playstation, Hot Wheels, O’Neill, Gridiron Labs, Microsoft Xbox, Piloti, and others. He has lectured and given workshops at multiple art and design schools, including Art Center, Concept Design Academy, Red Engine School of Design, and Brainstorm.

He was born and raised in Houston, Texas and currently lives in Southern California. Check out his professional design work at www.behance.net/christopherarmstrong