Healthier food & better flavor. Perfect accessory for a frying pan. Fat-reducing cooking technology

Dry heat is what distinguishes an outdoor grill from a skillet, where the food is either stewed or stir-fried in oil. Flagship is designed to create the full effect of a fire grill in the comfort of your own kitchen.

It looks astoundingly simple to use because it is. Flagship Light slides into any skillet and heats up from it’s surface. You can oil the skillet or use it without any grease.

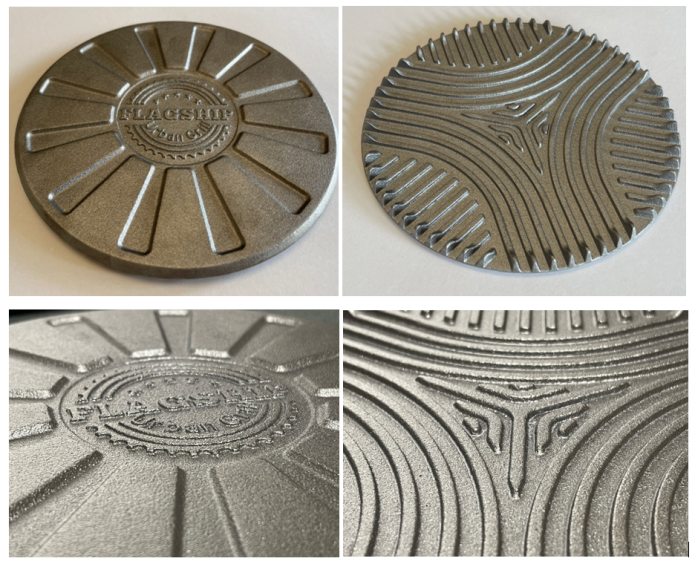

The bottom of the grill is machined after casting to shed off extra weight. Exclusively for the first Elite batch, we added polishing to create the ideal smooth contact surface. Time-consuming hand polishing is not intended for mass production, but it’ll be included in the limited Elite Batch as an appreciation for your early support.

Ideally polished bottom of first production units. August 20, 2021

It started as a joke. Let’s fry eggs and cheese on the grill. The awesome results led us to experiment with grilling anything and everything. The conclusion: if it can be fried, it can be grilled. Just as tasty, and much healthier.

Flagship doesn’t need a skillet when used outdoors on open fire, park-style BBQs, charcoals or camping stoves. It wouldn’t take much space in your bag and will help you to control the temperature to grill perfectly crispy food in any unfamiliar conditions.

Before acquiring the brand and becoming Flagship, our team members helped the original company manufacture and deliver rewards. We partnered with a cast iron facility. Now we own IP and production molds to ensure prompt manufacturing.

All our products come with a guarantee. Flagship Grill Light comes with a limited LIFETIME WARRANTY. We tested it enough to be sure it’ll last a lifetime.

HOW IT WORKS

The dry heat system sets Flagship apart from most grills and frying pans on the market. While the cooking ridges are leveled, the proprietary draining channels are sloped to remove excess fat and moisture. The bottom of Flagship Light is engineered to keep drained liquids outside of cooking area, maintaining swift heat transfer and uniform temperature distribution.

As in any outdoor grill, the dry heat technology helps to preserve flavors and keep the food juicier. At the same time the food isn’t soaked with oil and fat.

Mmm, cheesy, not greasy! All Flagship products are pre-seasoned with natural vegetable oil and ready to use. And the more you use it, the more non-stick it becomes.

Kitchen space is essential but sometimes we need to cook more food than one pan could accommodate. Flagship Light saves space and time. Convert several skillets into grills and cook surf-n-turfs or burgers and veggies at once.

Our optional Flagship Easy Grips are made of extremely durable stainless steel with non-slip silicon inserts. You’ll be able to order any accessories on the post-campaign survey.

REWARDS

Shipping is not charged during the campaign to keep it as low as possible. The straight cost will be passed on to you at the time of delivery. Please see the shipping rates in the above graphics. Less expensive “slow shipping” options will also be available.

The Flagship Easy Grip

TIMELINE

PRODUCTION STATUS

As of August 16, Flagship Grill Light is officially in production. The first 68 units are finished and being air-shipped to the US for the final inspection and beta-testing. The first mass production run of 5,000 units is scheduled for September 17 to ensure October and November shipping to our backers.

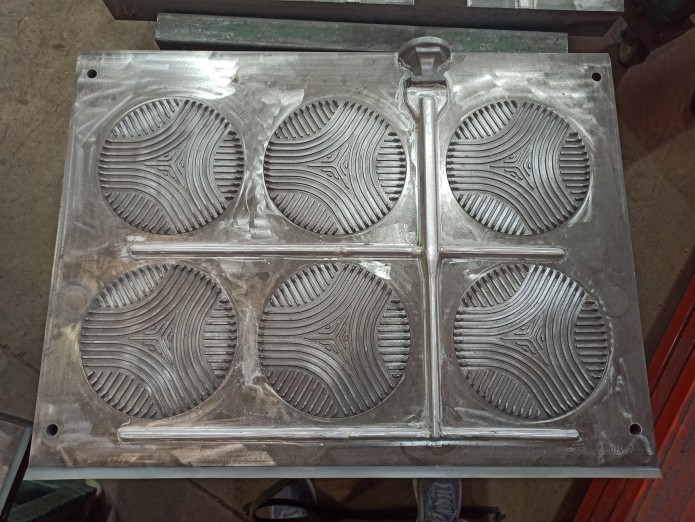

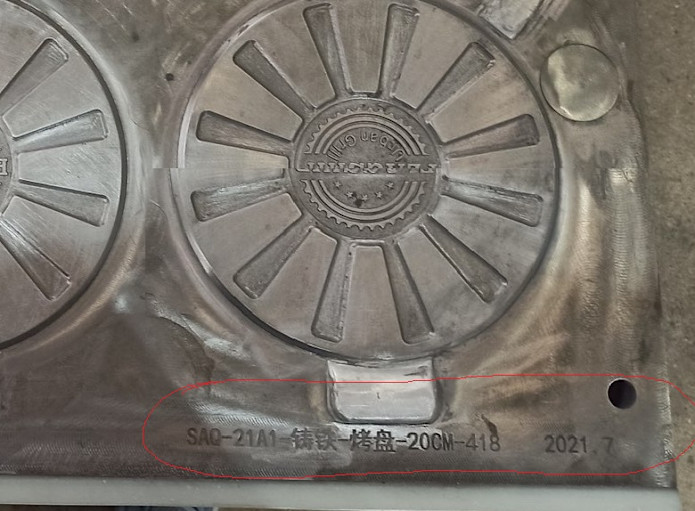

The mold has been tested and adjusted, the initial run was performed. The Flagship stainless steel mold on the pictures below weights over a ton and allows to make 6 grills per each working cycle. It took almost 2 months and 3 adjustments for specialized factory to make the mold. Now it’s been thoroughly tested and moved to our production facility.

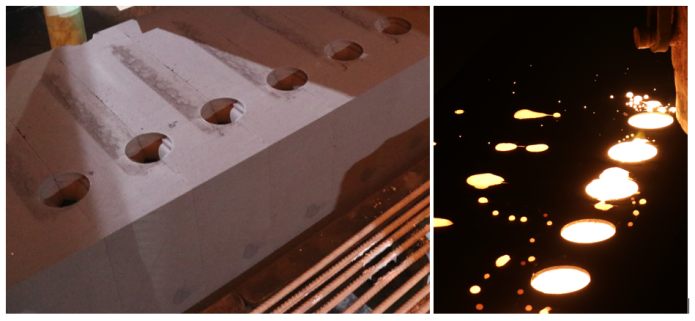

These kind of molds operate on disamatic lines and consist of two parts. They create sand forms and melted cast iron is poured into the forms at 1,450 C (2,700 F). Then it cools down and special vibration machines disperse the sand and extract raw grills that are moved to secondary operations department. These lines take a large commercial building and capable of manufacturing several hundred Flagship Grills each hour.

The Flagship Light mold marking shows that was made in July 2021. We fulfilled our promise to start the production during the Kickstarter crowdfunding campaign.

Here are the original Flagship Grills on a disamatic conveyer line. The melted metal is poured.

Cast iron is not smooth or black when i’s freshly casted. Besides it rusts within hours while in moist environment. You can even see the oxidation on the grill in the video. We sandblast each Flagship grill, then machine to shave off extra weight. After that, its polished, to make them very smooth, and season with vegetable oil to make it rust-proof.

After polishing and seasoning it moves to packaging, and then the complete products are moved to final quality control.

First Flagship production test batch in the factory QC room, Aug. 18, 2021. Each grill undergoes 2-step quality inspection before it is sealed and ready to be shipped to you. Now, they are almost ready for your kitchen.

Our production partner is a highly reputable company that produces quality cast iron cookware for many years. They operate in one of the biggest cast iron factory in the world with access to the most sophisticated equipment. Many potential partners were not able to produce Flagship Light due to its complicated shape and thin bottom, and we were happy to find the production partner with vision and engineering wizards on staff.

TEAM

Our team is made up of people from different countries, backgrounds and of different ages. Nevertheless we all share the same passion: cooking. We want our food to be something special every time. But at the same time, we try to eat healthy. That’s why it was an indoor grill that brought us together. We already worked as a team manufacturing the original Flagship grill pans and solved all possible production hiccups doing that. At the moment, we are the 9 people, including CAD designer from Washington, DC, USA; industrial engineer from Philadelphia, PA, USA; cast iron plant production manager from Shijiazhuang, China; logistics coordinator from Guangzhou, China; shipping specialist from Riga, EU; PR director from Los Angeles, CA, USA; graphic designer from Kiev, Ukraine; chemical engineer from Moscow, Russia and a business administrator from Baltimore, MD, USA. We have also established working relationships with two logistics companies to ensure smooth and timely delivery of all rewards to our backers. The team is well-prepared and qualified to guarantee the best product delivered to your kitchen.