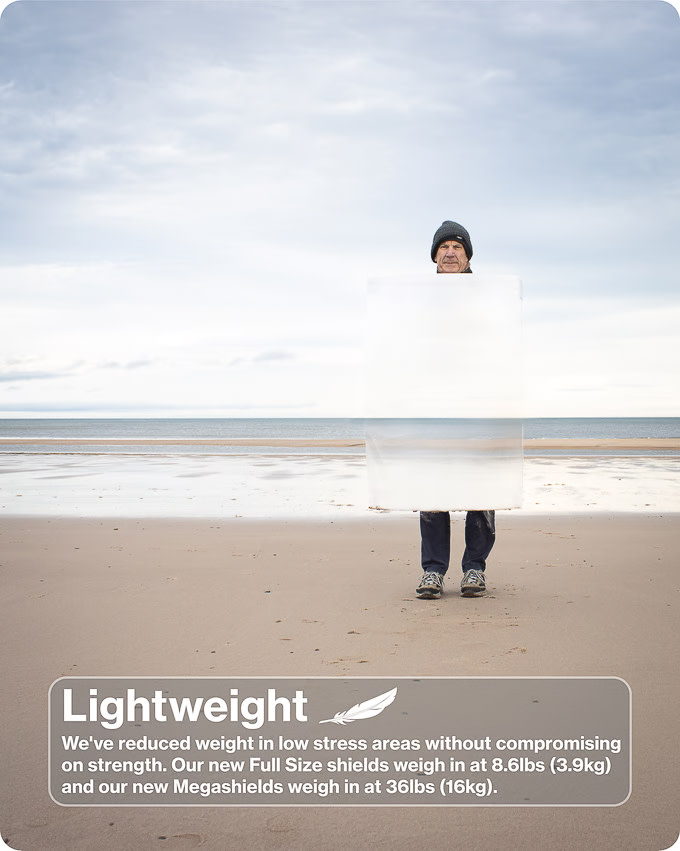

All New INVISIBILITY SHIELDS. Lightweight. Portable. Next Level Cloaking. Pack Down Small.

We’ve spent the past four years developing and testing optical cloaking devices. We’re now seeking your support to share our new and improved, second generation invisibility shields with the world!

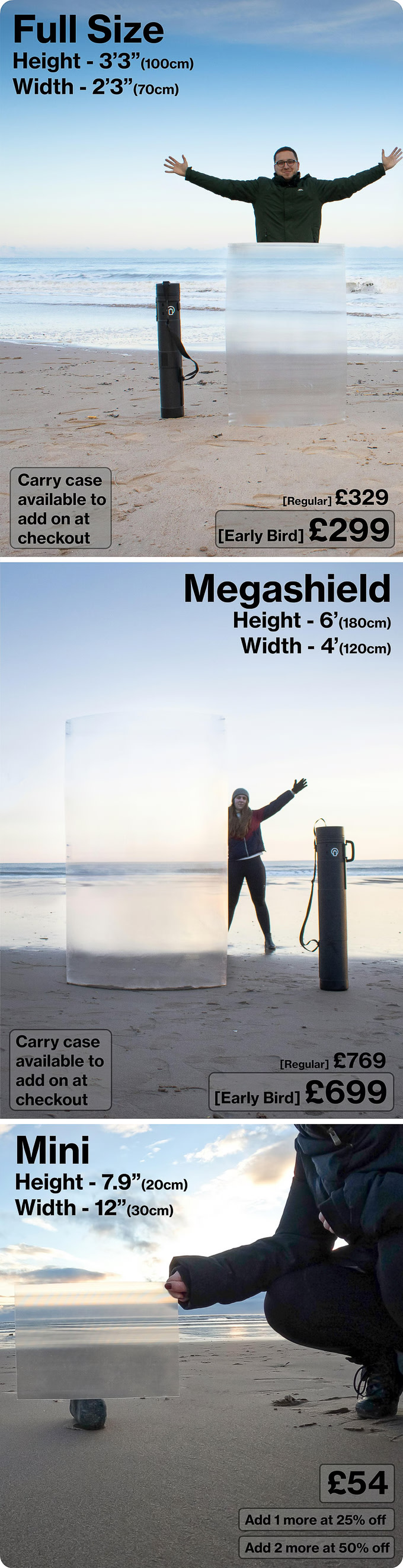

The front face of our new Full Size shield is 17% bigger than the previous version and the Megashield is three times bigger than that, measuring 6ft (1.8m) tall, making it large enough to hide multiple people standing side by side.

Our new shields have been completely redesigned to be more stable when left free-standing, easy to hold and easy to take wherever you want to go.

New ergonomic handles make holding and carrying the shield far more comfortable, whilst keeping your body in the optimum position to stay hidden.

Our shields won’t take up valuable space when you’re not using them. The Full Size shields and Megashields can be completely disassembled and packed in dedicated carry cases (available to add on at checkout).

Full Size shields and Megashields are constructed from a high grade polycarbonate offering improved strength and durability.

Instead of using adhesives to bond layers of material, the main body of each shield is extruded from a single piece of material. This allows more light to pass through, creating a brighter, clearer and more vibrant rendering of the background. This also completely prevents adhesive related artefacts, like air bubbles and streaks, making our new shields look great at any distance.

Our Full Size shield takes the average novice 10 minutes to set up and pack for the first time and the Megashield takes around 15 minutes (with two people). We recommend setting up and handling the Megashield with two people on account of its size. Instructions are included to assist with the first assembly.

No power source is required, simply assemble your invisibility shield and place it in front of whoever or whatever you wish to cloak.

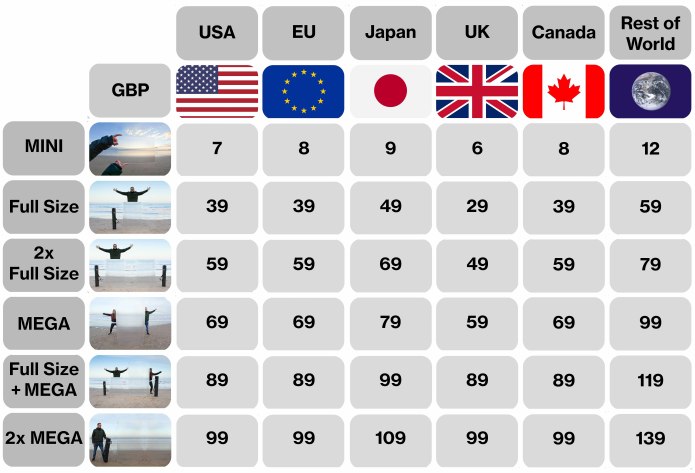

Don’t see a shipping rate estimate for your specific selection of rewards?

To calculate your estimate, add the estimates for each tier included in your selection.

Doing a final shipping calculation closer to the time of delivery allows us to find the minimum cost for you, in your specific location based on shipping prices at the time. Expected charges can go up or down.

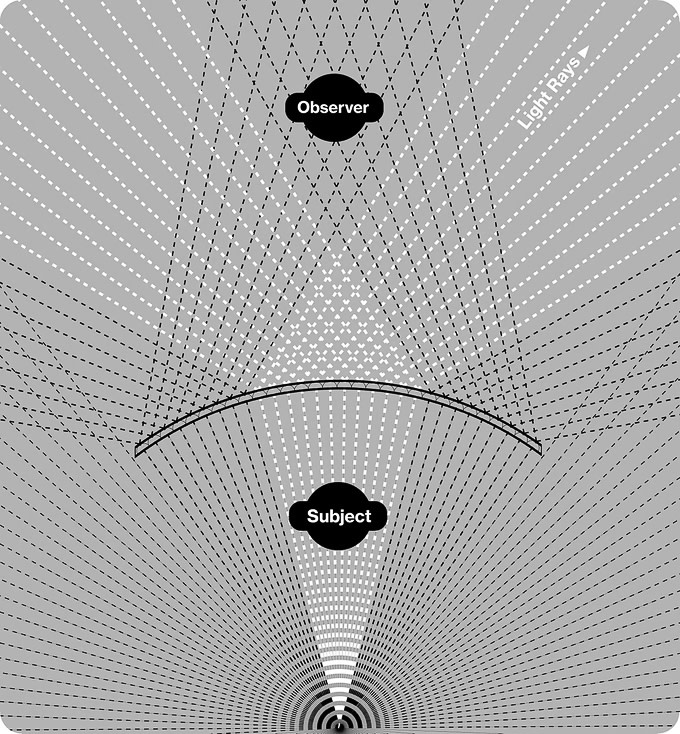

Each shield uses a precision engineered lens array to direct light reflected from the subject standing behind it, away from the observer standing in front. The lenses in this array are oriented so that the vertical strip of light reflected by the standing/crouching subject becomes diffuse when spread out horizontally on passing through the back of the shield. In contrast, the strip of light reflected from the background is much wider, so when it passes through the back of the shield, far more of it is refracted both across the shield and towards the observer. From the observer’s perspective, this background light is effectively smeared horizontally across the front face of the shield, over the area where the subject would ordinarily be seen.

The optical arrays we use to construct our shields are manufactured by extruding and then embossing a polymer to form sheets of elongate, convex lenses. In order for these sheets to manipulate light in the right way to create functional invisibility shields, the lenses must have a highly specific shape and each one must be formed with high precision as they are very small. To find the best properties for a shield, we’ve spent years testing different lens shapes with varying profiles, angles, depths, focus points and separation distances.

The shields perform at their absolute best against uniform backgrounds such as foliage, grass, rendered walls, sand, sky and asphalt. Backgrounds with defined horizontal lines work extremely well too and these can be natural features such as the horizon or man made features like walls, rails or painted lines.