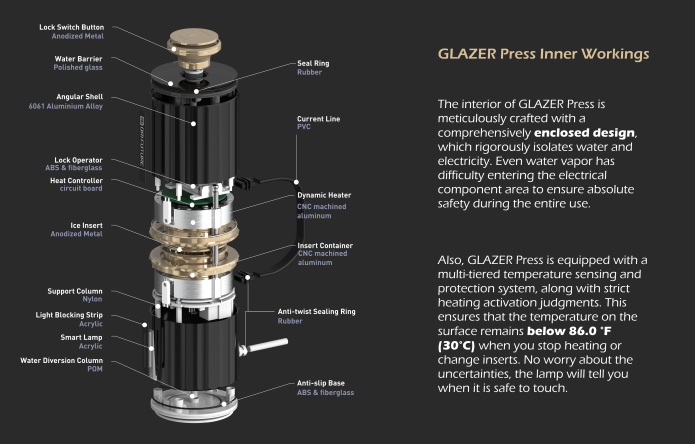

The next generation of ICE PRESS for Crystal-Clear Creations

As a beverage lover, you know how important the ice is. We are so proud to introduce GLAZER Press to you – The new generation of ICE PRESS. This product possesses both efficiency and creativity. With different metal inserts, it makes ices into various shapes in a very short time.

Let’s see why we need GLAZER Press. It’s not just a ice press but a game-changer in its field.

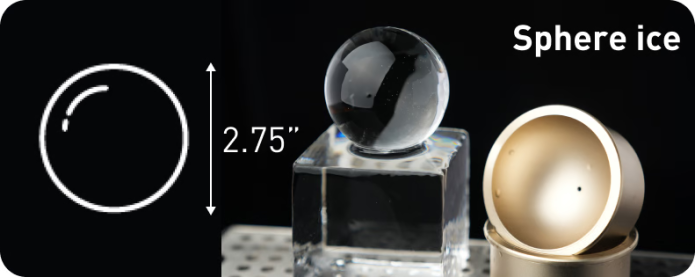

Ice press has been existing in the market for a long time, widely used by bartenders and home bartending enthusiasts. Despite the fact that most of the presses are able to make a perfect ice sphere, we have encountered several problems. The most remarkable issue is large time consumption. The pressing time is determined by many factors, such as the ambient temperature and whether it is preheated, etc. In some inappropriate situations, it may take more than 20 minutes to finish the pressing, which is really terrible. It cannot be used back-to-back: waiting for the ice press warm-up can be so long. Moreover, most of the ice presses are made of metal, resulting in high cost and heavy weight.

GLAZER Press is a revolutionary ice press, which greatly shortens the ice pressing time to nearly 2 minutes through its Dynamic Melting System and innovatively extracts the ice inserts from the current ice presses. This innovation fosters greater creative freedom and significantly mitigates the manufacturing cost of metal, resulting in a lighter and more portable gadget. We aim to redefine ice pressing, seeking to open up a new world of transparent ice making and promising an experience for every supporter.

We are deeply grateful to our first batch of users for embracing GLAZER Press, even in its early stages, and for sharing their authentic experiences. Their support and feedback are invaluable to us. Let’s hear what they have to say about GLAZER Press!

[Shot and Edited by LIVY]

———————————

Update #1:

A Great Thanks to David Johnson for his unboxing.

Update #2:

A unique way to use GLAZER Press as an earlier user.

[Shot by David & edited by ORI Future Team]

A race against one of the most powerful traditional ice press. Completely an easy win.

[Shot by David & edited by ORI Future Team]

———————————

A Great Thanks to Michael to give us a quick review on GLAZER Press after 2 weeks’ use.

[Shot by Michael]

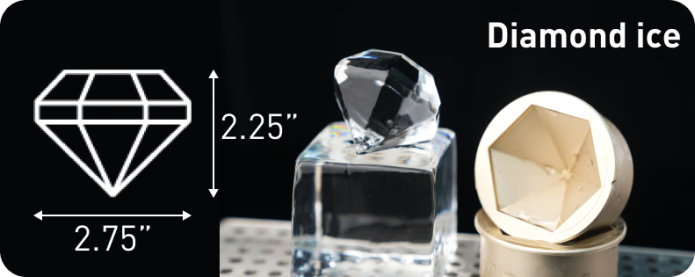

GLAZER Press is a game-changing innovation product in ice pressing field. Reducing the amount of metal used allows for the creation of unique ice shapes like skulls, diamonds, etc. With the cutting-edge Dynamic Melting System, it takes less than 3 minutes to curve the ice, delivering a brilliant ice-pressing experience.

Nowadays, ice presses are mainly utilized in bars and related places due to its high cost (whose price can reach 1500 USD if the whole body of the machine is copper). We are trying to reduce the proportion of metal so that customers can avoid paying for the expensive but unnecessary materials.

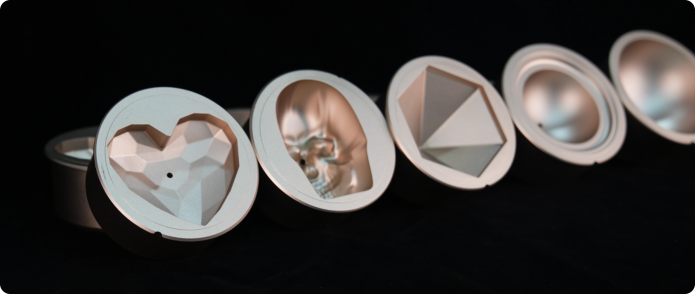

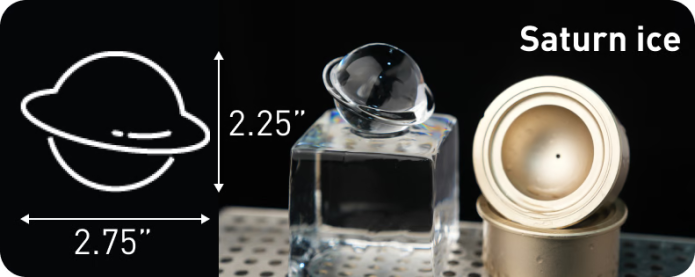

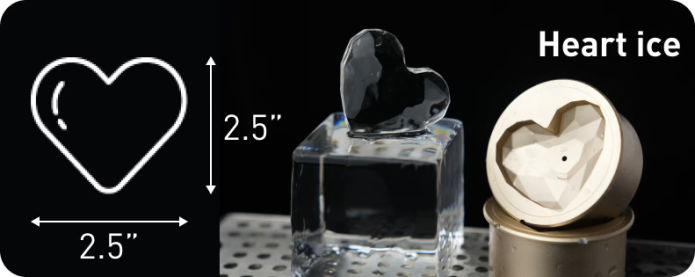

Thanks to the reduced size of metal inserts, we got the opportunity to make more inserts to make more ice in different shapes, such as skulls, diamonds ,etc.

When using traditional ice presses, you will find that after a single pressing, it becomes frozen, rendering it temporarily unusable until it reaches an suitabletemperature for the next pressing process.

To address this issue, we’ve figured out an innovative solution – Dynamic Melting System.

Rest assured, the heating feature of GLAZER Press only activates when you need it. Our Dynamic Melting Device guarantees a flawless shape within merely 2 minutes, striking the delicate balance between preventing ice cubes from overheating due to excessive temperatures and avoiding delays in pressing time caused by insufficient warmth.

Everything operates in optimal conditions, and every second of pressing has been precisely considered.

We consistently adhere to our own design principles, embodying the company’s “N+1” work philosophy and product vision while prioritizing an extra step for the benefit of our users. This dedication has resulted in innovative designs, all of which have been endorsed by GLAZER Press.

Because of the heavy weight and lack of design considerations, the current ice press requires both hands to hold it when moving or transporting, which is troublesome.

To enhance user convenience, we’ve innovatively added a rotary button switch to the top of GLAZER Press, and it will be locked when you rotate it clockwise. With this improvement, using the ice press is a breeze. Simply unlock it to begin and effortlessly secure it with just one hand for swift transportation after use. This not only simplifies storage but also makes it easier to use, especially outdoors.

GLAZER Press adopts minimalism and intuitive button design. The light will show you the condition of the product.

When GLAZER Press is plugged, the light turns on and enters the standby state; when you are planning to press an ice or change inserts, the light will be in a breathing state, and the light turns red after pressing the button switch for up to 3 seconds. Also, you can disturb the process anytime with a single click and wait for the light to turn white. Once the process is complete, the light turns calm blue, signaling that the ice is ready for use.

The inserts of GLAZER Press utilize magnetic suction and pin shaft for double positioning assistance. Reserved finger spaces around the fitting parts allow for easy replacement of inserts.

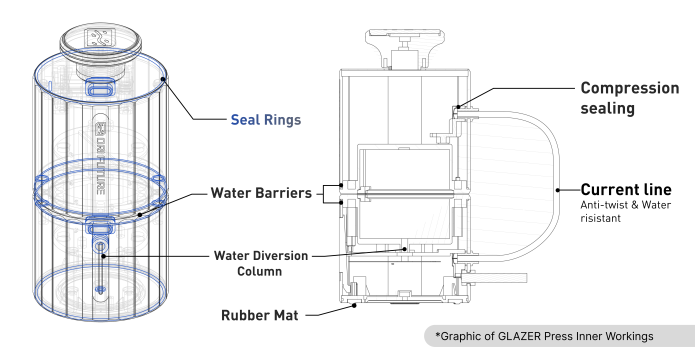

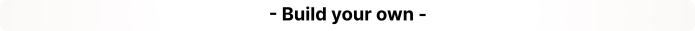

GLAZER Press utilizes high-power and Dynamic Melting System, safety is our foremost priority during the design phase. We employ a rigorous, fully enclosed design for water and electricity isolation and implement numerous redundant safety measures in our electrical components to ensure precise control and protect against overheating temperatures. As a result of these design considerations, GLAZER Press effortlessly cleared the IP65 waterproof test.

The interior of GLAZER Press is meticulously crafted with a comprehensively enclosed design, which rigorously isolates water and electricity. Even water vapor has difficulty entering the electrical component area to ensure absolute safety during the entire use.

GLAZER Press is equipped with a multi-tiered temperature sensing and protection system, along with strict heating activation judgments. This ensures that the temperature on the surface remains below 86.0 °F(30°C) when you stop heating or change inserts. No worry about the uncertainties, the lamp will tell you when it is safe to touch.

As for the judgements, the GLAZER Press initiates heating only upon pressing the handle. And then, the Dynamic Melting System activates. Once the procession is done, heating ceases instantly, safeguarding against burns and preserving the intactness of the ice shape. Also, you can pause heating whenever it is needed: click the button to stop heating and restart it by pressing the button and holding for another 3 seconds. Customers are allowed to touch the surfaces and inserts once the lamp displays calm blue.

GLAZER Press is IP65-rated, ensuring its resilience even in challenging conditions. From home bars and outdoor camping trips to poolside parties and private yachts, it adapts to various scenarios and demonstrates its superb performance.

GLAZER Press incorporates metal materials in critical components with the same coating process as the faucet, enhancing both its texture and corrosion resistance. Thanks to the replaceable inserts, it can be disassembled and cleaned individually. Moreover, any residual water on the press can also be easily wiped away. This guarantees the ongoing maintenance of cleanliness for GLAZER Press.

We firmly believe that the inserts can be endlessly crafted and innovated, and we invite developers from all backgrounds to collaborate with us to revolutionize GLAZER Press inserts. We will take great care of your ideas and opinions on the new inserts, unveiling new inserts that align with your satisfaction at the appropriate moment.

As one of our valued backers, you have the unique opportunity to personalize your ice shapes by crafting your own 3D model of the inserts you desire and sending it to us. This enables you to receive ice inserts tailored exclusively to your preferences. Custom insert pricing will be determined based on the complexity and creativity of your design. Additionally, we encourage you to share and explore innovative concepts for GLAZER Press inserts within our Facebook Group.

GLAZER Press support global shipping. Please be aware that shipping and taxes are not included in the pledge levels. For users in the United States, we will choose a more economical transportation method while ensuring the fastest delivery time. For other areas, we will mostly ship by air unless you have special requirements.

Below are our estimated shipping fees. The shipping fee may be adjusted based on actual costs. We have the responsibility to provide everyone with a more reasonable shipping solution.

GLAZER Press is made and cultivated just like our children. Our goal is to distinguish it from existing ice presses. To achieve this, we used all-metal materials to ensure a refined tactile experience. Simultaneously, we strategically reduced the weight of non-supported internal components to improve comfort and ease of operation.

In our metal fabrication process, we utilize metal extrusion for the housing and CNC machining for both inserts and heat transfer components. Furthermore, we employ various techniques, including grinding, sandblasting, ultrasonic cleaning, PVD (Physical Vapor Deposition), and hard oxidation for surface treatment, ensuring that the texture of GLAZER Press meets and exceeds both your and our expectations.

Regarding hardware design, we integrate top-tier control chips from Europe. Paired with the exceptional design skills of our hardware engineers and robust materials, we effortlessly manage intricate PCBA designs.

See more details in our Product Journey Bolog Below:

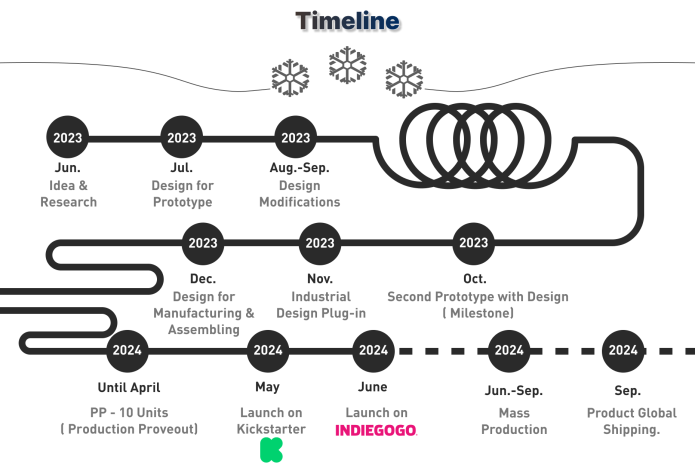

- Idea Inspired – June 2nd, 2023 – An idea is born, and all of us are excited to deal with this innovative thing.

- Key Component Verification – June 9th, 2023 – We do MVP verification.

- 3D Print Verification – June 23th, 2023 – Use 3D printing to verify product form and get inspirations.

- The First Prototype (MVP) – July 1st, 2023 – From concept to reality, see our MVP.

- Product Reliability Testing of Ice Pressing – July 5th, 2023 – Systematic MVP feature testing(A journey for ice pressing).

- The Second Prototype with Design – August 2nd, 2023 – Visual innovation of the second prototype.

- Ice Inserts Designing, Manufacturing and Inspiration – September 20th, 2023 – Unlocking new dimensions in iced drink & beverage.

- The Modification of Second Prototype (Milestone) – October 12th, 2023 – See the fusion of design and mechanism. Celebrate for our milestone!!

- Industrial Design plug in – November 15th, 2023 – The path to technology: We are bringing a new design for GLAZER Press.

- Design for Manufacturing & Assembling – December 15th, 2024 – GLAZER Press is about to live!

- Product Proofing – January 17th, 2024 – Perform a Solid Proofing with 10 sets of GLAZER Press Pre-production.

In the heart of the bustling cityscape, a revolution to elevate the drinking experience brews in the everyday experience of enjoying a beverage. Here is the world of ORI Future, a company born from a passion for innovation and a relentless pursuit of excellence in beverage appliances.

“ORI Future – Beverages from the beginning to the end” is not just a tagline; it’s a commitment to excellence at every stage of the beverage experience. We are always by your side and try our best to help you make any complex beverages like cocktails, coffees, non-alcoholic drinks, etc. We are willing to revolutionize home living with smart beverage appliances by combining innovative technology and designs based on users for the ultimate convenience in beverage preparation. Cheers for the future of home drinks.

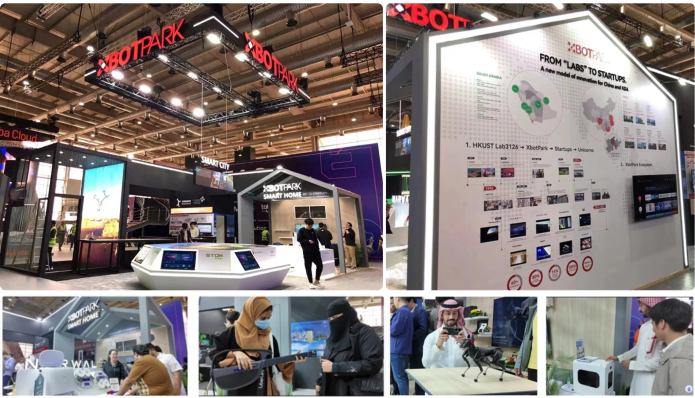

ORI Future was founded in 2022 by a group of young individuals with tough dreams. Much like some well known companys like DJI, ECOFLOW, ePropulsion, we share a common name called XBOTPARK, which corresponds to its huge supply chain system.

Until now, ORI Future is a company with nearly 30 people, including seasoned engineers and creative designers. Some of them have accumulated over 20 years of experience in their respective professions and have wholeheartedly chosen to join us in pursuit of our shared dreams.

In our cherished moments away from work, we’d like to stay at our office, taking great pleasure in crafting cocktails and mocktails for one another. Here, almost everyone has their special cocktails, and using the ice produced by our products makes drinks unbelievable.

Additionally, some of us are also whiskey aficionados! We relish the opportunity to share these distinguished whisk(e)y reviews with each other, explore their complex flavors, and sometimes visit distilleries together.

GLAZER Press is just the beginning. It symbolizes our commitment to pushing boundaries and exploring new horizons in beverage world. Join us in this adventure, where every drink is a masterpiece, and every sip is a step into the future.