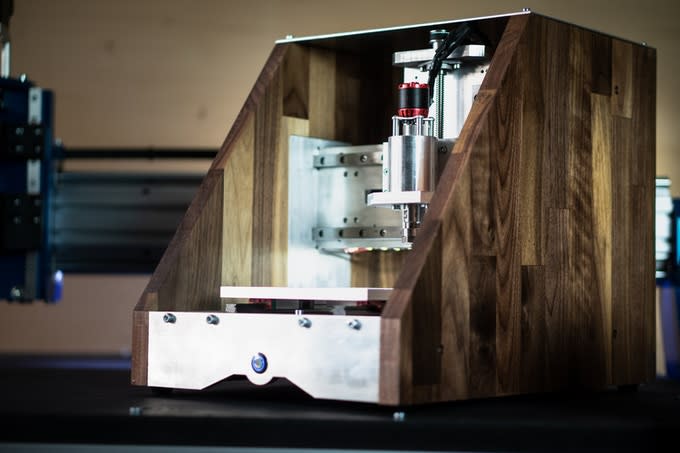

Mill metal, wood and acrylics with quality CNC machines made in Germany

After raising over $300,000 on Kickstarter, CNC ONE is back on Indiegogo!

Watch our update to see the current state:

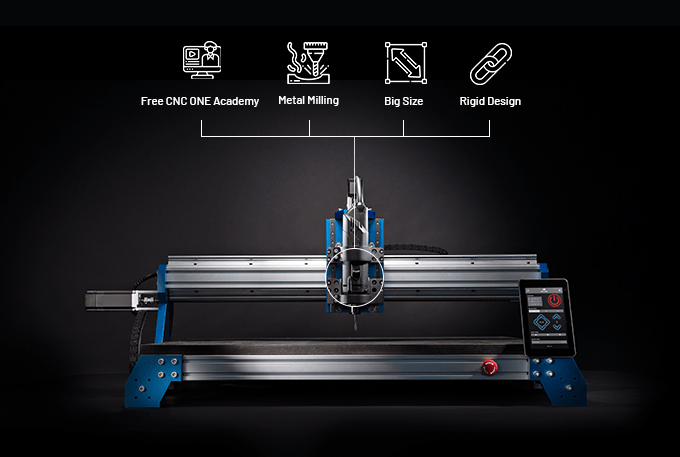

CNC ONE’s CNC Academy, big size, rigid design, and metal milling capabilities makes it the perfect entry into the world of CNC milling. It combines easy use with high quality standards, making it the best CNC router you can buy at this price.

CNC ONE machines help to make an unlimited number of things on your own. Either to make others and yourself happy or to start a business.

CNC ONE can machine a wide range of materials at high speeds. Mill a wide variety of materials like aluminum, wood, acrylics, MDF, steel sheets, brass, PCBs, foam and carbon fiber.

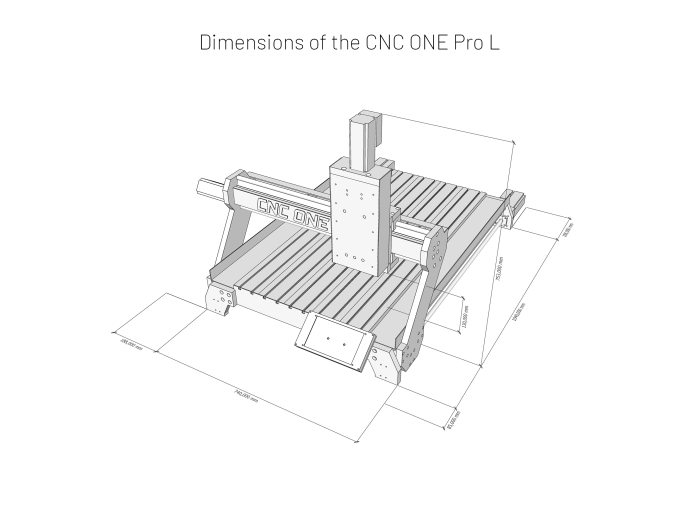

CNC ONE is one of the largest CNC routers in its class. The big dimensions and high robustness allow you to mill projects in any size up to 1,000 x 1,000 x 80 mm or 39.4 x 39.4 x 3.2 in.

CNC ONE is not a toy or an average entry CNC machine. It is powerful enough to mill, and not only engrave, all commonly-used metals like aluminum, copper, brass or steel sheets.

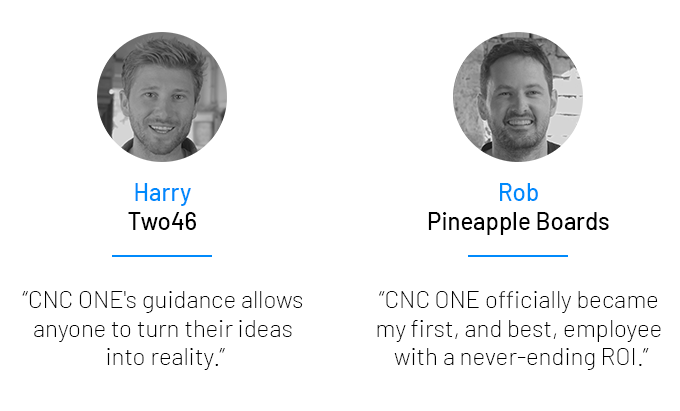

CNC ONE is great for both personal hobby projects and massive business projects, thanks to its immense power and versatile capabilities. CNC ONE is like your first employee that you only pay once and continues to pay for itself time after time.

Even if you love working with your hands, not all products can be sold for a profit this way due to time constraints and physical complications. Instead, allow yourself to focus on the creative and fun tasks and let CNC ONE do the rest.

Increase your profit by selling customized products. Offer products in your online shop that can be personalized on any scale.

A fashion startup approached us asking for a machine to customize their stylish backpacks and fashion products. So we designed a compact engraver and CNC ONE milled it in just 8 hours! (only the spindle was made on a lathe)

Other Crowdfunding campaigns sold a CNC engraver like this for €2,000 – CNC ONE made this in just a few hours, saving thousands of Euros.

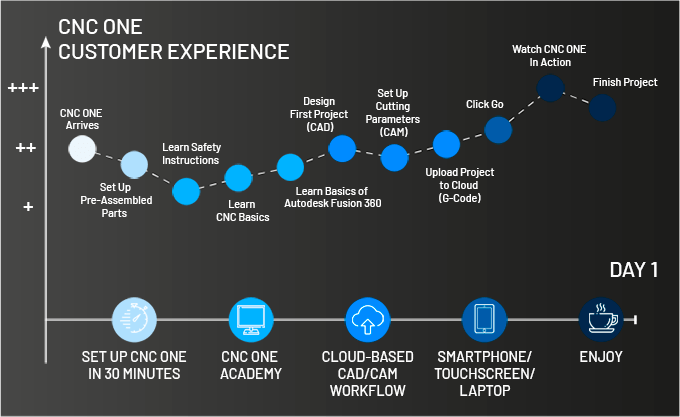

The main focus of other CNC manufacturers is on the machine and not the customer. The result is that it takes especially unexperienced customers a long time to surpass the CNC learning curve and to begin having fun with machining.

Watch our Co-Founder Filip talk about the challenges you encounter with other CNCs and what a great customer experience looks like with CNC ONE.

We know that CNC machining can be a daunting topic. To prove the opposite, we developed the smoothest CNC experience for our customers. Our free CNC ONE Academy and hassle-free workflows empower even the least experienced beginners to machine beautiful projects on their very first day.

We at CNC ONE guide you by your hands from the moment your CNC journey begins until each creation is finished. We want you to have a simple, trouble-free experience with our machines. This makes CNC ONE easier to use and more fun than other CNCs.

We offer our CNC ONE Academy to all our customers for free. In more than 50 video lessons, we show you how easy CNC can be. Learn everything you need to CNC machine like a Pro.

Other machines in this price class come in pieces. This means hundreds of screws, soldering cables, installing different software etc. CNC ONE comes with pre-assembled components. For you this means tightening a few screws and connecting cables. All explained in our CNC ONE Academy. And ready to run in 30 minutes.

Our workflow is optimized for you: going from an idea to the finished project is usually a lengthy process that involves multiple tasks and software programs. Each step requires a laptop and a permanent cable connection to your machine during operation.

For CNC ONE, we came up with a completely new workflow. We eliminated all those unnecessary steps and optimized our machine for the best free CAD/CAM software for hobbyists and professionals: Autodesk Fusion 360.

Additionally, you can upload your projects to the cloud which makes it possible to separate the design and machine process. This way, you can model your ideas in peace at home and start operations with another device when you enter your workshop. If you prefer working offline, you can easily transfer your projects via Micro SD or USB.

Our CNC ONE Academy will guide you trough all the necessary steps to get the results you wanted.

(You can find additional information about our software specification in the section “Rewards”)

Watch Filip explaining our easy workflow:

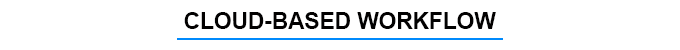

Other CNC routers are controlled by a laptop which is hard-wired to the machine via USB or parallel port. While operating, your laptop is covered in wood chips and sawdust. CNC ONE is utilizes Wi-Fi connections so that you can move your laptop freely.

Controlling CNC ONE with your smartphone is magical. Leave your laptop at home and mill your project with your own iOS or Android device.

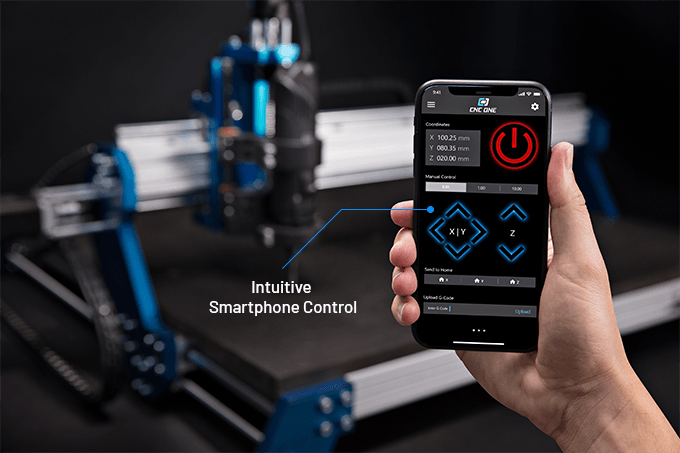

The included touchscreen gives you full control over the machine into your hands. Move CNC ONE or start machining your projects directly at point of use.

Precision is also a result of robustness. Other CNC routers use 10 mm aluminum parts or 3-5 mm steel sheet. On CNC ONE we use heavy 20 mm aluminum parts.

Our 20 mm gantry design has another advantage: CNC ONE is built to last. The strong design can bear operational errors. While other CNC routers suffer major breakdowns, CNC ONE has a broken mill.

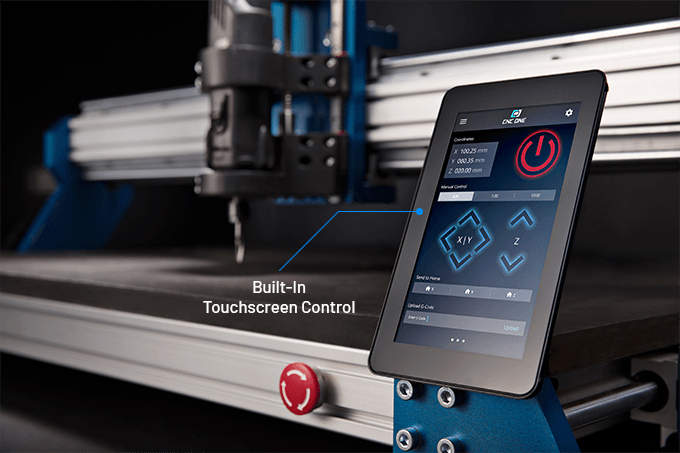

Because of its rigid design, CNC ONE machines are one of the largest in its class. The Pro XL and Pro XL Black Edition is equipped with a machine bed of 1,000 x 1,000 x 80 mm or 39.4 x 39.4 x 3.2 in. The standard z-height is 80 mm (3.1 in) and can be upgraded to 130 mm (5.1 in).

90% of non-industrial CNC routers use stepper motors. They are inexpensive but provide low speed and acceleration. CNC ONE is the first in its price class that uses servo motors. This makes it 4x faster than its competition. Be the first to take the next step in CNC technology.

See how fast our servo motors are:

High and repeatable precision is important if you plan to machine demanding projects. Most non-industrial machines use cheap belt drive or lead screw systems. The result: your project does not look like its 3D model and you must throw it away.

We use ball screws on all axes. This system allows high precision and excellent repeatability, while enabling low wear, and low energy consumption.

Machine demanding projects whose parts fit together perfectly without gluing, screwing or rework. Our motto: if your parts do not fit, you cannot call it a CNC!

Whether you mill 1 or 10,000 units of the same project, CNC ONE gets the job done in a repeatable quality that you can even sell. CNC ONE even allows you to machine solid aluminum with high and repeatable precision.

We designed our machines to add and change parts easily. Upgrade your CNC ONE at the checkout of this campaign.

We ship all CNC ONE machines and add-ons worldwide. Since we want to keep your shipping costs as low as possible, we will charge an additional shipping fee before shipment.

EU backers don’t have to pay any additional VAT. If you live in a non-EU country, additional taxes, VAT or duties may apply. The amount is subject to the laws and regulations of your country.

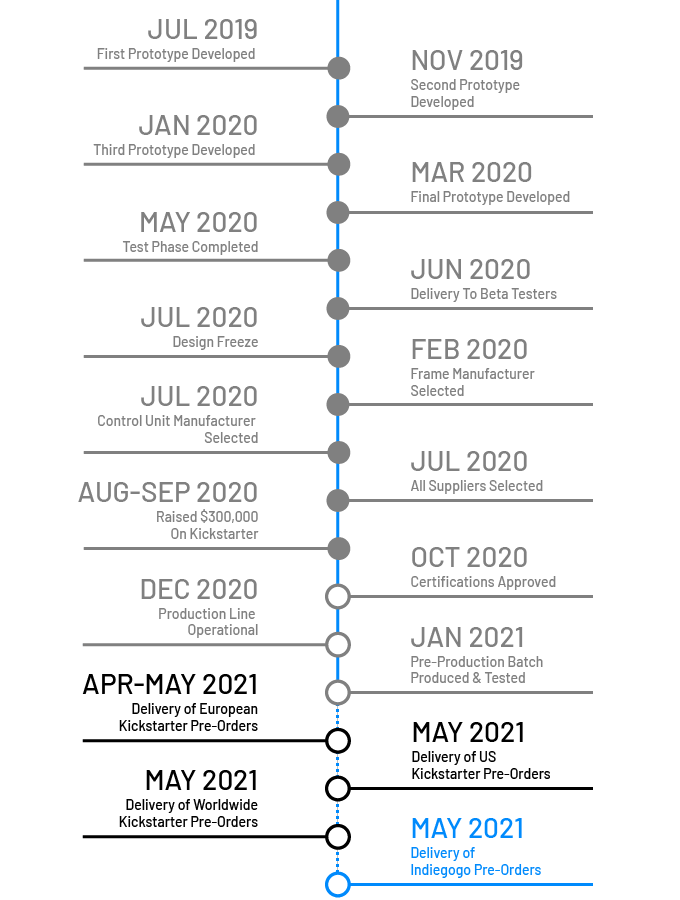

CNC ONE has been on a great journey. We are in the middle of production and we will deliver our first machines to all Kickstarter backers in April – May 2021.

If you order on Indiegogo, you will receive your machine shortly afterwards.

We are proud to manufacture and assemble each CNC ONE in Munich, Germany, with high-quality parts sourced from areas across Europe and Asia.

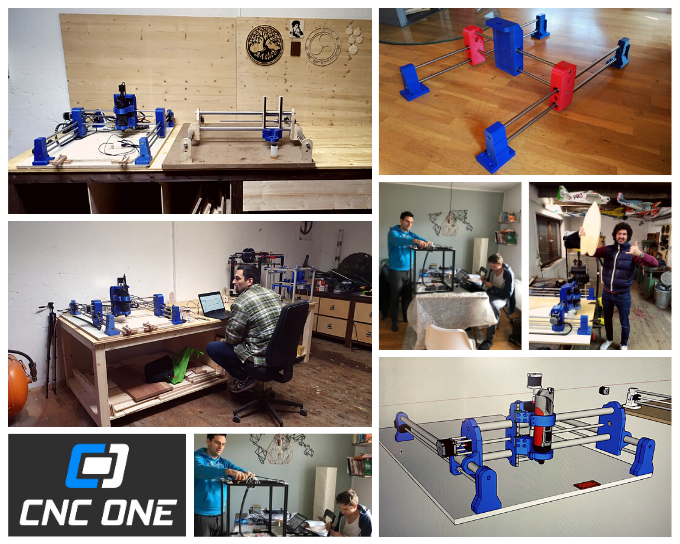

We are Sven (32) and Filip (34) from Munich, Germany. We met at university where we studied Engineering, and immediately became good friends. We even lived together for 2.5 years during our Bachelor’s.

During that time, we had the idea to build our own company one day as we always thought that we would have the perfect working match. Filip loves to develop technical things and Sven loves to work on business ideas. In the last years, we worked at manufacturing companies in Germany. Filip learnt to build machines and hardware products including all the electronics, and Sven learnt how to produce them efficiently. Additionally, Sven did his PhD besides his job which gave him a good understanding of how manufacturing will develop over the next decades. By combining our abilities, starting a business that develops and produces smart hardware products was the obvious choice. But how come we exactly decided to create CNC ONE?

The idea of CNC ONE started because we weren’t happy with existing machines. As Engineers, we worked for German manufacturing companies and therefore with industrial CNCs. For our own projects we first used our own developed 3D printers, but they were not enough to create high-quality prototypes. CNC-Machines are perfect if you need different materials by speed. So we wanted to buy a CNC, but couldn’t find one that fulfilled our needs as the industrial ones were too expensive and the cheap ones didn’t have enough power. So we decided to built our own CNC: an affordable router that is easy and powerful and we want you to have the same fun with creating as us. A year ago we built our first prototype and what you can see now is the 5th version of the machine as we are always improving.

Icons made by Freepik from www.flaticon.com