The evolution of suspension bike technology – lighter, stiffer, more reliable.

DATUM

…the first mountain bike with innovative, integrated, lighter, stiffer, more reliable: Analog Suspension.

We’re already fully funded through Kickstarter, and production is already underway.

We’re now able to offer additional pre-orders through the Indiegogo InDemand platform.

DATUM is a 140mm rear travel All-Mountain / Trail bike designed and manufactured in California, USA.

Its all-new ANALOG suspension matches both the better descending and pedaling attributes of the industry’s most respected four-bar suspension systems, while delivering significantly reduced weight, carrying more water bottles, and offering improved reliability.

the Datum’s natural habitat

The culmination of years of development and ride testing on trails, bike parks and all-mountain terrain, Datum is our reference, our middle point between XC and DH. It’s a mountain bike for riding in, across, up and down mountains – we’re not going to call it a quiver-killer, but it’s a bike which will deliver miles of smiles whether you’re showing up for your local Wednesday Night XC World Championships or Sunday’s Shred Session Enduro Series.

Its 27.5″ rear wheel should be paired with a 29″ front wheel and suspension fork having 150mm or 160mm travel.

ANALOG Suspension

… delivers predictable kinematics, improved reliability, chassis rigidity, light weight, 2x water bottle and long dropper capacity, and more.

Analog suspension was conceived from the realization that on most 4-bar suspension systems the upper link undergoes large angular displacement, which can cause the linkage’s instant center¹ to move wildly, and for the leverage rate to get all funky². This can cause the suspension’s behavior to change unpredictably throughout its travel, which in turn results in a loss of control for the rider.

The slider in the Analog system does away with the short upper link parts, yet functions like an infinitely long link. Doing so removes that angular displacement problem altogether, this helps keep migration of the Instant Center under control throughout the travel. The suspension performance is thus controlled throughout its travel resulting in a predictable, surefooted ride.

¹[sometimes called the virtual pivot point.]

²[scientifically speaking]

Kinematics derived from performance leading predecessors. Yes, the spelling will be corrected before this goes live.

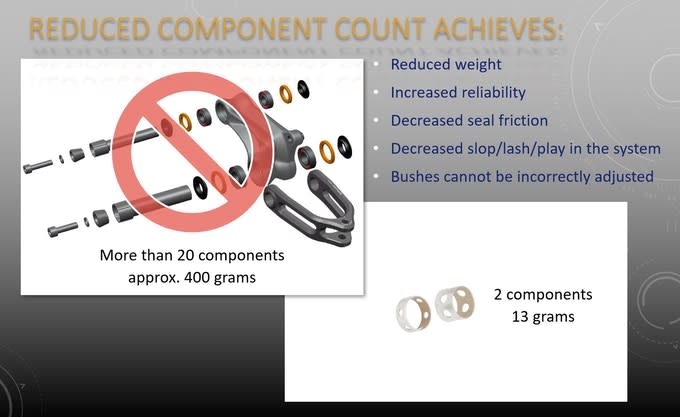

There are several side-effects to replacing the upper link assembly with a slider, happily these are all good or great:

- Increased chassis stiffness, because there are fewer parts to flex.

- Reduced free-play in the chassis, because there are fewer pivots and bearings in the system. Using only 3 pivot sets, and low leverage ratios minimizes the stack-up of backlash in the system.

- There are no shock eyelet bushings, which are a common free-play, stiction, and maintenance problem area on most other suspension designs.

- Significant weight saving – typically in the 200-600g range.

Many links, bearings and pivot shafts links replaced by 13g of sleeve bearings.

- Capacity for the longest dropper seat-posts, because the seat-tube runs straight all the way to the bottom bracket.

- Room for two water bottles in the front triangle, there’s also a third bottle location under the down tube.

- Low 2:1 suspension leverage ratio, which reduces the loads on the frame, shock and oil.

- Longer shocks, which allow improved spring and damper design, for optimal suspension performance.

- Improved reliability, because there are fewer parts which could break.

- Improved reliability, because there are fewer seals where water or mud can penetrate, the seat tube shields the shock from rear-wheel-splatter, and the shock’s wiper-seal cannot be opened by side-loading (fork-type bushings resist that). Also the top surface of the lower link is angled so that any mud falling onto it is deflected away from the drivetrain.

- Reduced environmental impact compared with other suspensions because fewer parts are made.

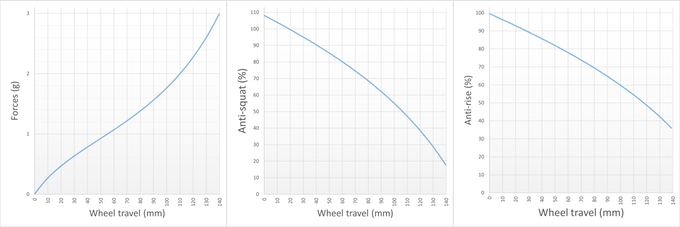

A picture tells 1,000 words. So this is all I’m going to say here about the kinematics:

You don’t need to lose sleep over these graphs, we did that for you already.

OK, that’s a lot of tech. Here’s a little huck-to-flat to wake you up:

INTEGER Strut

…hidden inside the frame, it flows more oil, squeezes more air, and has fewer parts in an easily serviceable, low motion-ratio package.

Much of the technology which makes the most highly regarded off-the-shelf shock absorbers ‘special’ is intended to compensate for deficiencies resulting from having to squeeze performance out of the small space between the frame’s shock-eyelets, and to make them adaptable for use on all different bike models. The INTEGER Strut³ isn’t disadvantaged in these ways because there is no upper eyelet to limit its length, and because it’s a bespoke match for the Analog suspension mechanism.

The Integer Strut has a longer air spring, tuned to match to the frame’s leverage profile; and the damper holds more oil to resist overheating (fading), and allow higher flow rates through the damper piston (for improved control).

As a result, the Integer’s damper can use a relatively simple, very reliable damper design to deliver the best, most reliable performance.

³[a strut is a shock-absorber (spring + damper) which is combined with a structural component.]

The Integer Strut is over 12″ in length – bigger is better.

The Integer Strut is made of all metal parts, and can be fully serviced without specialist tools. It has an external dial adjuster to tune low-speed rebound damping (LSR), and an external lever to adjust low-speed compression damping (LSC). The LSC lever can be used to tune support through flowy terrain (e.g. pump tracks, berms), or as a climb-switch/lockout (though we really don’t feel that the Analog suspension linkage needs that).

Independent shim stacks are employed to control high-speed compression damping (HSC), low-speed compression damping (LSC). A cross-over shim stack, check valve and taper-needle metered orifice control high-speed rebound (HSR) and low-speed rebound (LSR) damping.

The Integer Strut and all the tools needed for a complete service

DIGIT Bikes

We are starting our business making only frames – not complete bikes. This is because Covid-19 has shaken the bicycle industry supply chain such that sourcing components will cause unacceptable delivery delays compared with supplying just the frame (more than a year).

This allows you to upgrade an existing bike, or to choose your preferred mix of parts. To use your favorite saddle for instance, rather than delay delivery by waiting for a saddle which you might switch out anyway (the lead time at saddle factories is almost two years!).

You will need an experienced bike mechanic to assemble the components. If you intend to assemble the bike yourself, please be certain that you are an experienced and competent bike mechanic.

The full list of compatible components you’ll need to complete your build are listed below.

Rewards

We’ve already invested heavily in the developing the Digit Datum, we need your help to Kickstart our Southern California manufacturing operation.

We will reward your support with a Datum frameset:

// DATUM frame features

// Custom butted aluminum frame. Made in Southern California.

// REAR: 140mm rear travel, fits 27.5″ rear wheel, tires up to 27.5″x2.6″, 180mm post-type brake mount. 148Boost axle included with frame.

// FRONT: match with 29″ front wheel 150mm or 160mm travel fork (140/150mm fork on size S). Fork not included.

// SHOCK/STRUT: Digit INTEGER Strut (External adjustments: air pressure, LSR and LSC damping. Internal adjustments: positive air volume, negative air volume, shim adjustment of LSC, HSC, LSR, HSR).

// SEATTUBE: fits 31.6mm diameter with internal dropper post routing.

// SEATPOST COLLAR: 34.9mm inside diameter, included with frame.

// HEADSET: IS41/52, Cane Creek Hellbender70, included with frame.

// BOTTLE MOUNTS: front of seat tube, top of down tube, under-side of down tube.

// DERAILLEUR HANGER: Sram UDH, included with frame.

// BOTTOM BRACKET: Cane Creek Hellbender70 PF4130

// CRANK COMPATIBILTY: 30mm x 136.5mm spindle included with frame for Race Face Cinch Next SL/Next R/Turbine cranks. Cranks not included.

// CRANK COMPATIBILTY: 24mm spindle adapter tube included frame for 24mm cranks (e.g. Shimano/GXP). Cranks not included.

// ESTIMATED FRAME WEIGHT: < 7.25lbs, size L.

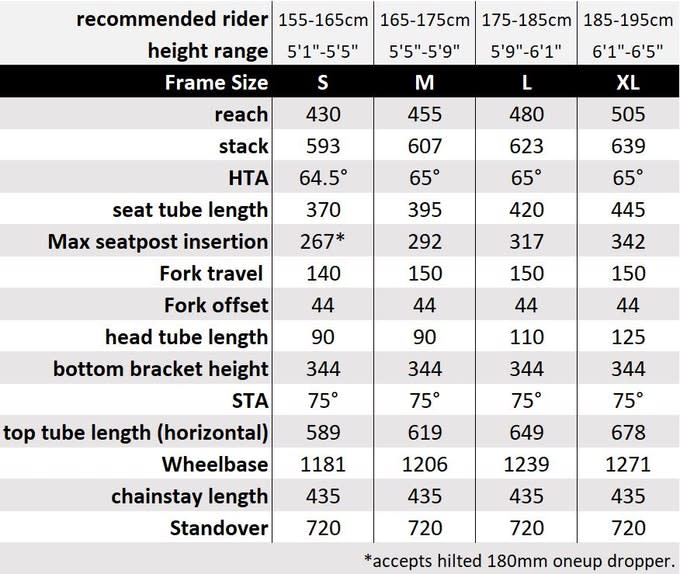

//Geometry

Please send of a message if you need smaller or larger sizes than listed here. If there’s enough demand will may add XS and XXL sizes.

//Colors

Our stock finish is a black anodized, matte (blasted) finish, with anodized in silver graphics. It is a very lightweight and tough finish.

We can accommodate custom color choices with an add-on reward.

If you’d like a polished finish, please get in touch and we’ll get a quote for you.

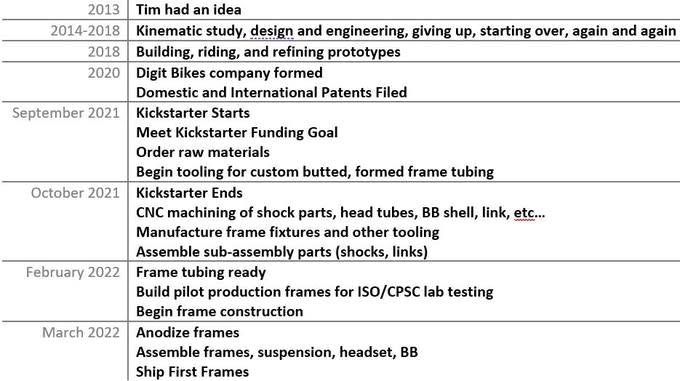

Timeline

*** The prototypes shown in the photos on this page are pre-production. Both the front and rear frame triangles will be made of welded aluminum. Anodize color samples are computer generated. The complete prototype bike shown weighs 28.4lbs with the Pike fork. Specifications are subject to change.

Risks and challenges

We have done our very best to mitigate the risks and challenges for this project.

We have been riding and tuning prototypes of the Datum for over two years, on real terrain from out-in-the-boonies epics to lift-assist mountain resort days – the design phase is complete and proven, and we have proven that these bikes are manufacturable, serviceable and reliable.

We are working in a new facility in Southern California, staffed by welders and machinists who have decades of experience fabricating bikes for the most respected boutique MTB brands.

In addition to the ride testing, we will be conducting lab tests to prove the ultimate strength and fatigue life. Shockingly these are not an industry requirement, your safety is paramount to us. Based on their experience, our engineers and craftsmen are confident that these tests will be passed with flying colors.

Material supply is our biggest challenge. Covid slowdowns have affected the entire bicycle industry, which is why even established bike shops have few bikes in stock. We have been working closely with material vendors to build a realistic picture of our lead time. The custom butted tubing has the most significant impact on the delivery date, our supplier advises that they might deliver ahead of schedule, but also to plan for the worst.

While the frame tubes are being drawn, butted and formed, we will be busy preparing tooling, fixtures, manufacturing processes, and the machining the shock strut and linkage parts.

Environmental commitments

Long-lasting design The suspension can be fully maintained by a competent mechanic with standard tools, little special knowledge is required. Service manuals and how-to videos will be available. Customer service agents can also offer guidance or via mail-in service. A coupon is included with each frame for the first mail-in service of the rear shock.

Reusability and recyclability The Datum is made of aluminum, one of the most-recycled metals in the world with a well established recycling chain. Unlike many other materials, aluminum more than pays for its own recycling in the consumer and industrial waste stream. Recycling aluminum saves more than 90 percent of the energy required versus producing new metal.

Sustainable materials Reduce > Reuse > Recycle. The most sustainable materials are those which aren’t even used. Fewer parts are required for Analog than with existing/competing suspension bike frames. Fewer parts require less material, using less resources and less energy. Reliability is also increased which should increase the frame’s service life.

Sustainable Distribution We’re manufacturing these frames in the Southern California, which will (for domestic customers) require less international shipping miles than for foreign manufactured frames. California where we’re making these frame generates most of it’s energy from renewable sources – 95% in 4/2021 .