We deliver the smallest and lightest bike multitool that ever existed for any kind of bicycle!

Daysaver – The Reason Why

It has always bothered us that we bikers must choose between having either a useful but heavy and bulky tool or a small and light one – as we want it to be – but inconvenient to use. The common concepts are based on foldable tools. The disadvantage of such concepts is that many screws are not accessible because of the bulky design, and you do not have the right lever when it comes to applying the proper torque. In recent years, the trend has shifted to “hide” tools in the bike – in the cranks or the stem. But this concept requires proprietary systems that fit only one bike at a time. So we either had to accept the situation or tackle the problem ourselves.

The Innovation

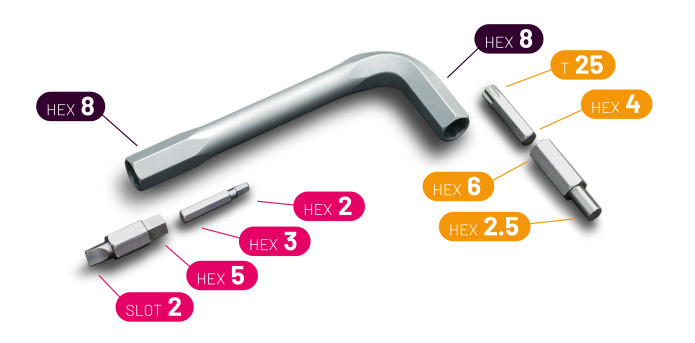

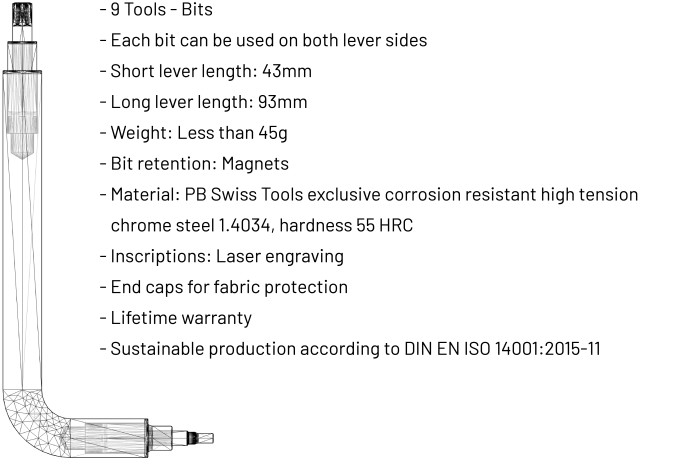

It took some time and elbow grease, but the final solution impresses by simplicity: We nest bits in bits. Simply flippable as needed. This way, we manage to include 9 tools on the classic Allen key shape at an unbelievable 45 grams.

We asked you, cyclists, out there which screws you have on your bikes. From your answers, we concluded that with eight tools, you could solve most problems during a ride – on almost any bike. The 9th was then defined by the backer community. We got a lot of feedback and the verdict of the community was that it needs a HEX 2.5.

That’s how you get a multi-tool that is 93mm long and 43mm wide (with bits), which you can either put in your jersey pocket without the tool pulling at your jersey. And of course without ruining the fabric – the Daysaver comes with end caps. Or attach it directly to your bike using our bike mount.

Features

The multitool designed in this way offers a whole range of advantages. With a bulky minitool you can’t reach many screws on your bike properly. Result: worn screws or scratches on the frame. With the simple and slim form factor of our tool you can get to every screw and tighten or loosen it in the right way. That is a promise!

Screws are sensitive creatures. With the wrong torque they are either broken or tightened too loosely. With the two different lever lengths of our tool you can give each screw the necessary amount of love. Your screws will thank you with endless fun.

Since we are not a tool manufacturer, we searched for a partner who understands our concerns and meets our quality and durability demands. We did not have to look far. Here in Switzerland, practically on our doorstep, we found a manufacturer that is known worldwide and renowned for their quality standards: PB Swiss Tools.

As our manufacturing partner, they will produce your Daysaver, and we give you a lifetime warranty on it. So we can proudly say, without boasting: Daysaver works with the best and delivers a 100% Swiss made product: designed, engineered, and produced in Switzerland.

Bits in bits works like this

Specifications

The press on Daysaver

The Story behind Daysaver

Hi, we’re Daniel, Elam, and Peter. We create innovative ideas for our customers for a living. Over the years, we have seen our customers become successful with our ideas. Now, the time has come to make our creativity work for us. As passionate bikers, it was obvious to us where to start – where our fire burns. We invite you to join the party.

Tinkering for the best multi-tool to take on your ride

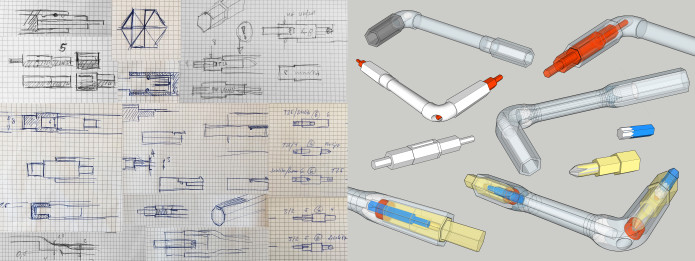

In winter 2020, goofing around in the snow, Dani brought up the idea of solving the multi-tool problem cyclists face once and for all. So we started thinking about it. Especially Dani, the tinkerer among us, occasionally called MacGyver, couldn’t get the challenge out of his head. Every minute his wife and kids were busy or sleeping, he tossed around the perfect bike multi-tool problem.

Building the actual product

As a result of such sessions, we got a clearer idea of what a mini-tool could look like. But even a great idea is not yet a product. So, we used a method that we had already successfully applied in countless customer projects and took a week off for a design sprint.

That was hard work! Who’s our target group, and what are the use cases? What does the customer journey look like? How can we validate our idea with the community to determine if our idea is as good as we believe?

At the end of the design sprint, we had gained clarity about how we needed to realize our idea of the perfect mini-tool. We had the fundamentals:

- No compromise in quality, size, form factor, and weight!

- A rigorous focus on the problems that can occur on the road!

3D Print Prototyping

So far, so good. Now we wanted our vision to materialize. So we hopped over to our trusted 3D printer. And we were more than thrilled with the first shot!

Ambushing our desired partner

With this first plastic prototype, we approached PB Swiss Tools, not knowing how they would react. Would they partner with us? Their reaction was overwhelming. They liked our idea so much that they started refining the tool with us. In the following months, we started working on the prototype development of Daysaver with the engineers of PB Swiss Tools.

And then came the day we held the first metal prototype in our hands, only a few months after the first sketches. That feeling was indescribable.

First torque tests

Does the tool withstand the stress of maximum torque? With PB Swiss Tools we have an experienced partner who carried out the strength tests. The result? The key withstands 97Nm maximum torque. And the bits also withstand more force than the maximum defined torque.

Long-lasting design

With the Daysaver’s lifetime warranty, you won’t have to buy another bike tool for on the road. This is very important to us, because we are strictly against the make-buy-dispose-mentality.

An idea became reality

We scraped together our savings to pay for the first steps in developing the tool out of our pocket. We were so convinced of our tool that we agreed to accept the financial risk. The many positive feedbacks and inputs from the community encouraged us to carry on. Together with PB Swiss Tools, we have achieved our first goal and have completed the prototype phase. We have drawn up and processed an extensive specification sheet: Torque levels for each bit, handling, form factor, coating, rust resistance, weight, ecology, and security. Now, with your support, we are ready for the next phase.

The second important step in tool development is to bring the tool from the prototype to series production. That means defining and testing the manufacturing process, adjusting the settings on machines and material, producing 0-series, etc. And then to take the final step: the actual production of the tool. We took this hurdle as well and reached our financing target on Kickstarter after 3 days. At the end of the campaign after 30 days we reached 300% of our financing target. An idea became a real product, which is now available for all bikers.