Eliminate landfills by processing solid waste into value-added products with electric arc processing

Short Summary

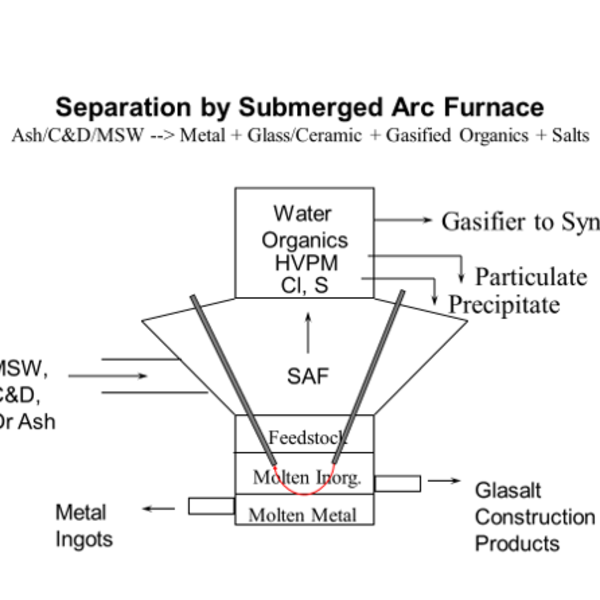

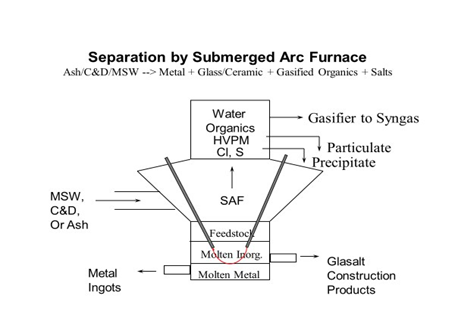

My name is Tom Eddy and I have been involved in solid waste processing for 30 years. Initially I was a Thermal Engineering professor for 20 years at various universities where I taught every thermal Science course on the books and developed a couple in the plasma processing area. This led me into research at the Idaho National Laboratory where I was Principal Engineer and Tech Leader of the Plasma Processing group. Our job became to determine how to process radioactive trash in a safe way into a very stable final waste form – like a basaltic rock. Others before us had developed the rock, but not how to process it continually at high enough temperatures. After about $200 million was spent by various companies and laboratories in testing, We held an open workshop to discuss the results. The conclusion in 1995 was that a submerged arc furnace (SAF) with graphite electrodes was the optimum way to process both the organic (combustible) and the inorganic (ash) materials.

Subsequently three other INL engineers and myself (and my wife) started MeltTran, an INL spinoff, to commercialize the process for hazardous as well as non- hazardous solid waste. MeltTran built several SAF units, improving the design each time. Interest came from South Korea to build a prototype to process stored radioactive trash. You saw that unit in the intro video. A second simpler one was built for DARO in S. Korea as a portable display unit in Korea. Unfortunately the Asian recession of 1999 hit and cancelled the sale. The unit became the MeltTran R&D prototype which you also saw in the video.

MeltTran had many clients that wanted a unit that converted (non-radioactive) trash into value-added products that would help pay for the processing. The major issue was that the financing entities were not willing to fund a plant that was large enough to be economically competitive that was not yet up and operating. That issue and the Asian recession led to the MeltTran demise. It was ahead of its time.

Now, 20 years later we are trying to do a restart in order to focus on eliminating landfills as well as simplifying waste management. The restart needs to focus on the people who realize that landfills are contaminating our waterways and polluting our skies. The proposed ultimate solid waste processing machine will process anything, separate the organic materials from the inorganic material, as well as from the metallic material, each of which can then be processed into value-added products. All the input can be processed to the extent there is no waste. That’s right – No Waste. Please see our website www.eliminatelandfills.com for additional information.

What We Need & What You Get

This time around, we are breaking the project down into steps to bring the people along with us. Step 1 is to request $50,000 to provide the funds to get the campaign going. Step 1 includes:

1. Completion and publishing a detailed handbook of How-to’s for operator training as well as for educating waste professionals. The handbook has about 20 chapters on all aspects of design and operation and is already over 50% written.

2. The completion of three (3) more patents that are important to maintain a competitive edge in processing the waste as proposed. Three prior patents are near termination so are open to all. One new patent had just been approved recently.

3. Maintenance of the Eliminate Landfills website which is up and running now and will produce updates for potential investors and others interested.

4. Materials analysis of some tiles previously made for which funding was not available.

5. And to cover some non-labor administrative costs.

Step 2 will be an equity crowd funding appeal for $1.1 million to build and operate a university R&D 2-ton/day SAF system for R&D, operator training, and future IP development.

Step 3 will be the first commercial/industrial plant to process 150 tons/day of ash from a WTE plant to enhance their profit margin.

Future steps 4&5 will involve a construction & demolition (C&D) waste plant of 250 tpd and a MSW plant of 500 tpd. Each of these plants has similar inorganic throughput for similarity in design.

Budget Estimates

Most of the funds expect to be expended in the first three months. The latter three months are to account for delays in publishing and patenting, and to extend the web site. Much, if not most, of the work required is being contributed by the TMT personnel with limited compensation. Over half of the Handbook is already in first draft stage. The CF goal is $50,000 for Stage 1.

- Handbook Publication Costs 3,900

- Website & Maintenanence Costs 1,240

- Patent external fees 18,000

- Materials Analysis of Tiles 3,200

- Prorated rent, utilities, Insurance 2,040

- Crowd funding costs 4,310

- External professional services 3,100

- Honorarium to Handbook Authors 14,400

Grand Total 49,998

We have also generated a Trash to Cash board game that includes the steps to get a plant going, including the potential financing, operating and revenues. The game includes various technologies to process solid waste. Every player is a winner because they learn about different types of waste, how it can be made a raw product, and the management and engineering functions of such plants. A game will be provided to any one contributing more than $250.Contributors will be supplied updates of progress, may have their name listed as a contributor on the web page, and will be advised of the status of the Stage 2 equity funding which would get them in on the ground floor.

All the crowd funding funds obtained will be spent on the items in Step 1 above.

The Impact

The proposed project will not only lead to the elimination of landfills, but will simplify waste management. Let the SAF separate the different kinds of waste, not different trash trucks! We have 4 trash trucks going by every Wednesday. That could be 2 or even 1. Recycling is good, but inconvenient. Some items, like aluminum or newspapers, are good to recycle. But plastics are difficult to burn in WTE plants and they do not want inorganic materials which lower the heating value of the waste. Combining MSW with C&D waste and with trees/grass/trimmings is no problem. Let’s simplify the waste collection to the waste management companies, increase their margin, and reduce the cost to our communities. A 500 tpd MSW plant will service a population of 300,000 in a city.

The impact extends to coal and other ash landfills which have (or will) cause major contamination of some of our rivers. These ash landfills can be reclaimed by mining and processing the ash and ground or whatever by the proposes method. The same is true of MSW and C&D landfills, as well as low concentrated coal residue. This can make a large long-term impact on the environment.

The radioactive waste prototype built at the Korean Atomic Energy Research Institute (KAERI) by MeltTran and the Korean Heavy Industry & Construction co (KHIC, now Doosan) took 13 months to design, build, install and operate. It is a very sophisticate “machine” because of the radioactive trash input and the desired monitoring and measurements desired.

As Tech Leader of a Technical Management Team that has developed or is experienced in the SAF plant operation we are trying to help community solid waste managers to reduce their costs and the inconvenience of finding landfills which are a liability. The vendors and equipment for the technology are available and have served industry well. An Ash plant takes 2 years to design & build, a C&D plant 3 years, and a MSW plant about 4 years, all depending on the size. They are very similar to a WTE plant, but do not have a stack, can input a wider composition of waste and do not have any significant waste left over.

Risks & Challenges

We are restarting in steps not only to bring people into the project, but because we need to demonstrate the quality of the construction products generated. This will reduce the risk and therefore the cost of funding the WTE Ash processing plant.

Prior work at MeltTran was cut off by the inability to stop the foreclosure on a building for ~$200,000. The bank confiscated $2 million in SAF and other equipment and supplies which they auctioned off for about $75,000. As a result many of the tiles and flagstones were processed, but there was no funding to confirm the materials properties. Many of the tiles were found to be too glassy, brittle and cracked easily. The heat treatment is complicated because one can not reheat up to the necessary temperatures without softening or melting the tiles. Recently, we developed a method to do that which is one of the 3 proposed patents. The University R&D will give us time to verify and/or improve the heat treatment procedure.

Basically we have been there and done that, but need some verification of the probable quality.

Other Ways You Can Help

You can help by throwing a couple of bucks in the pot. The more people contribute it shows that the people are interested in getting something done that should be done, but does not bring big profits to the usual project financiers. But is is also important to show your support by visiting the www.eliminatelandfills.com website to give us some checkoffs. And mention the process to your community leaders. Get them involved, get the waste management professionals in your community involved, and inform your friends. We will be sending out campaign letters, but you will have more influence with your friends.

Indiegogo has some share tools you can us in this regard.

We appreciate your time to hear this appeal.