Stop microplastic pollution from your laundry & protect our oceans. | Zero replacement filter costs.

We created Gulp for one simple reason: microplastic shouldn’t be in our environment.

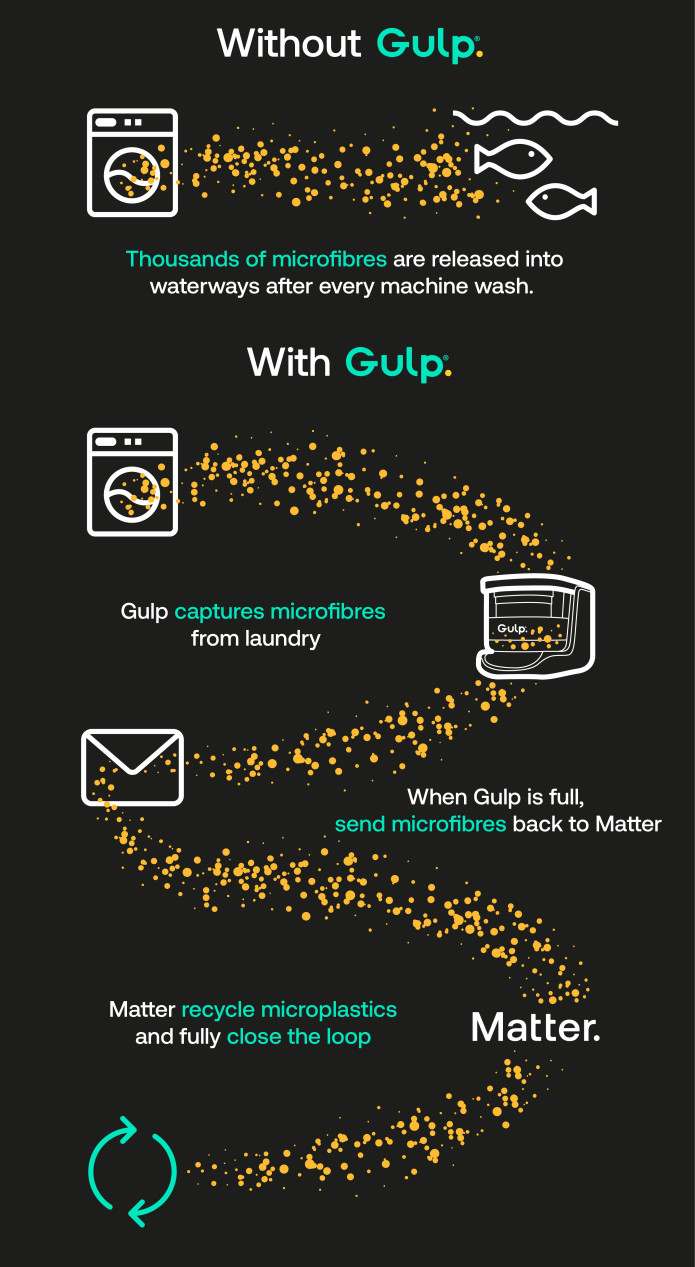

Every time we do our laundry, thousands of microplastics are released from our washing machines and pumped into our waterways.

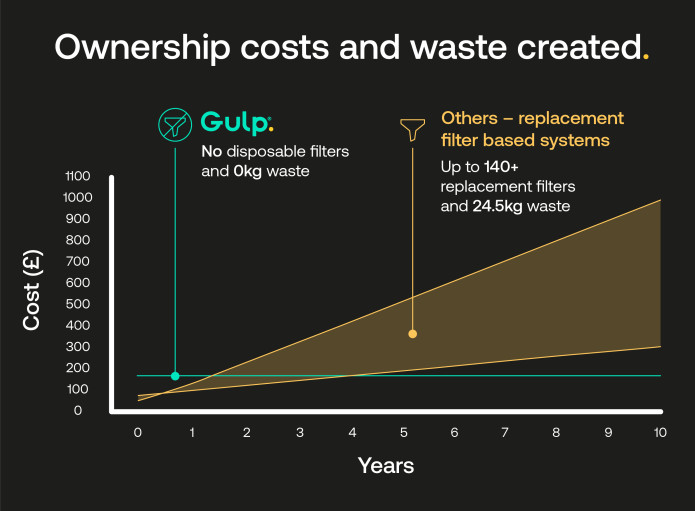

That’s where Gulp comes into play. The first, sustainable, long-lasting solution with zero additional filter costs and no disposable parts. Gulp swallows up the microplastics from your laundry before the ocean does.

Microplastics are contaminating our environment. They are found in our water, food and the air we breathe. One of the biggest sources of microplastics entering our ecosystem comes from synthetic fibres, ‘microfibres’ in our clothes which are released from your laundry.

Photos by Shifaaz Shamoon, Jean Wimmerlin and Gryffyn M on Unsplash

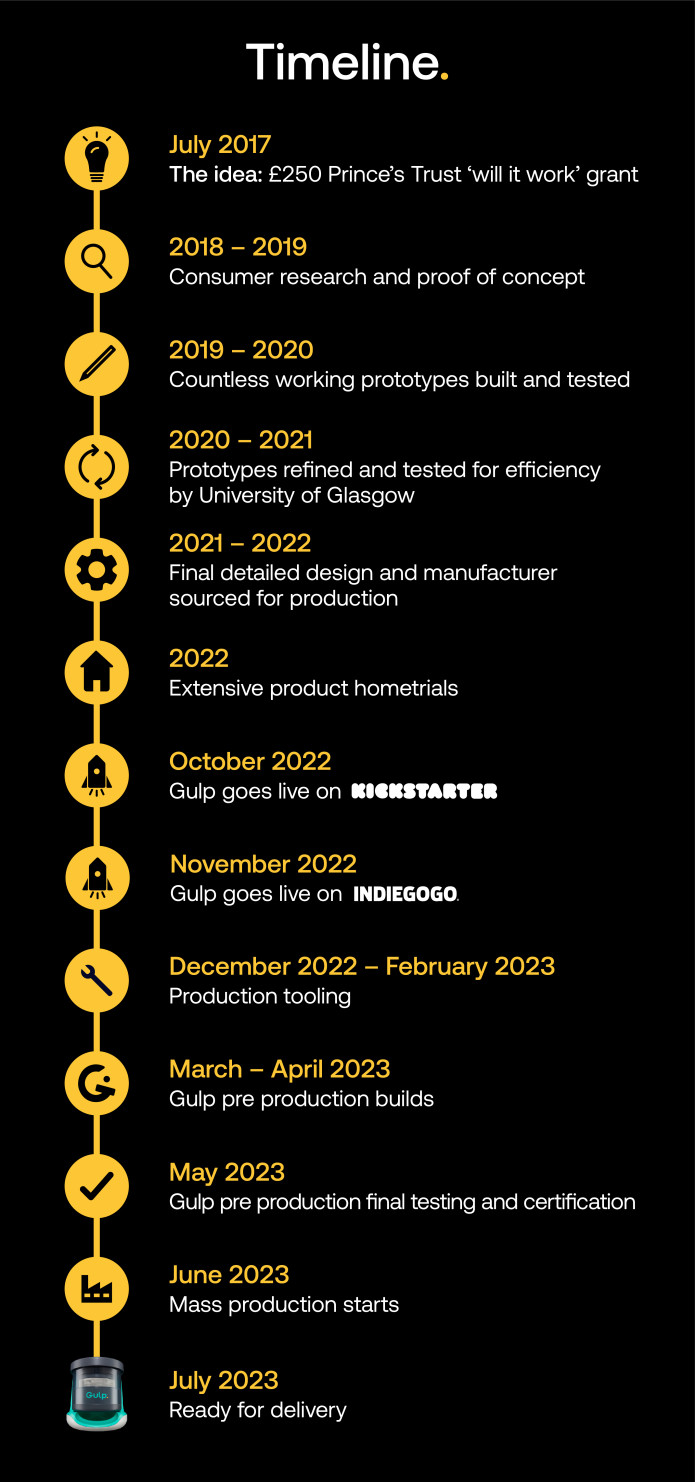

Every year in the UK alone up to 6,600 tonnes of these fibres are released from our washing machines into the ecosystem. That’s enough to fill 4,100 double-decker buses!

We believe Gulp is the most effective way to stop microplastic pollution from your laundry, with zero additional filter costs and no disposable parts.

Gulp’s patented self-cleaning technology means that not only do you never need to replace the filter, but it is also highly efficient at capturing microplastics. Thanks to its clever self-cleaning technology, Gulp maintains its high efficiency levels even as it’s filling up with material (more on this later!).

One Gulp at a time we can reduce our microfibre pollution – with each Gulp collecting on average this much fibre per year!

Fibre released per year – four washes per week for a family of four.

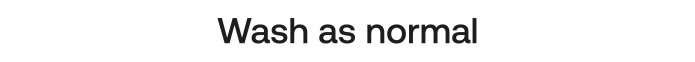

Gulp will work with any washing detergent and any wash cycle. This means you can continue to do your washing as normal, and Gulp will get to work.

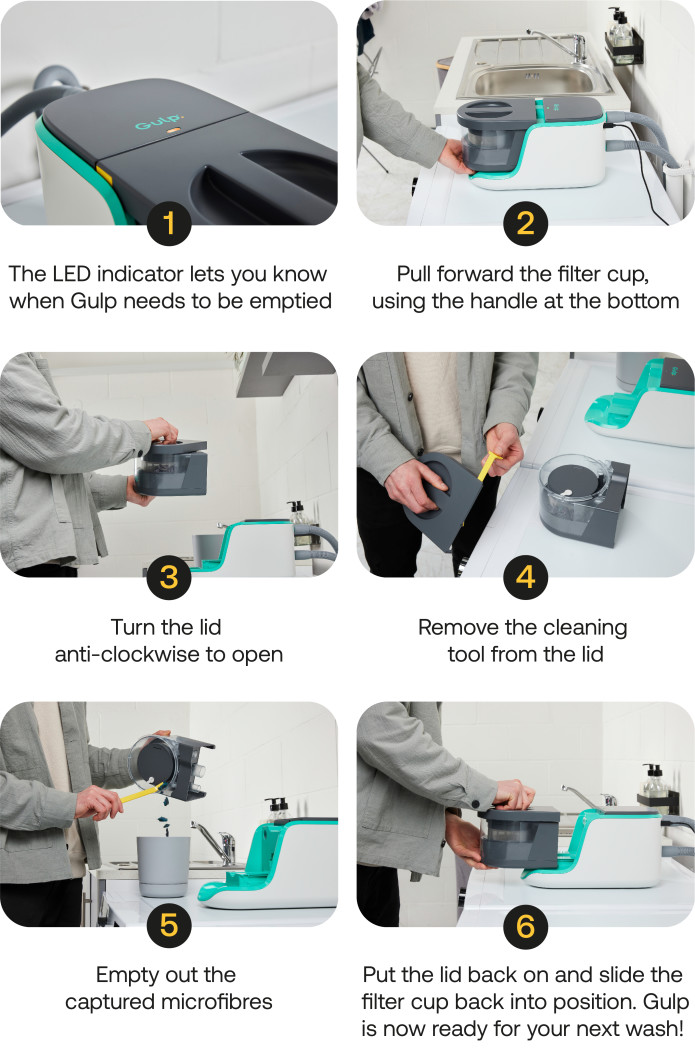

Simply empty the filter cup when the LED changes colour. The filter drains all the water so no buckets are required!

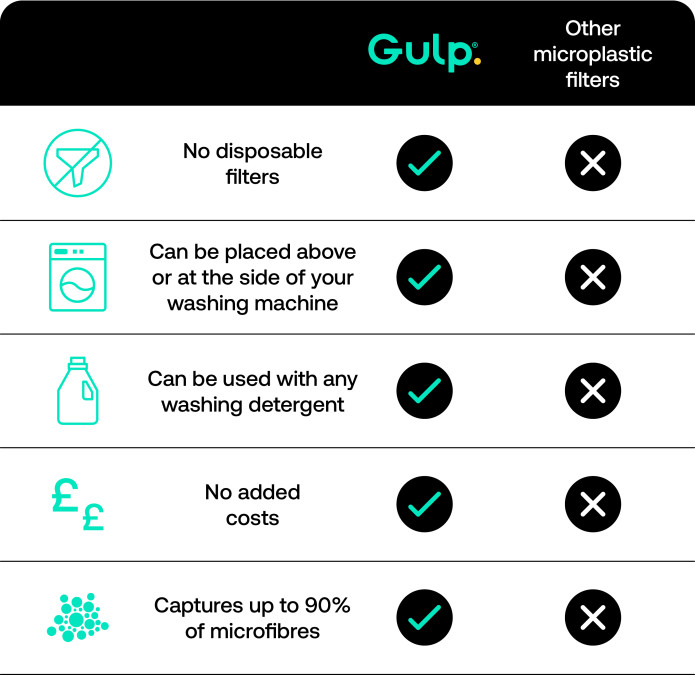

Gulp has been designed to be the most efficient, most cost-effective and truly long-term sustainable solution for capturing microplastic waste from your laundry.

Don’t just take our word for it, here’s how we stack up against other filters in the market…

When your Gulp is delivered next year, we will be accepting returns of microfibres captured by Gulp which will be used for ongoing research or recycled into new products. We will send you details on best practices for returning your collected microfibres nearer the time of product delivery.

If you are unable to send the microfibres back to us, that’s ok too. Putting them in the bin is much better than down the drain. In the UK and Europe, the majority of landfill is now sealed due to the regulatory requirements in the EU. This means that what goes in doesn’t come out.

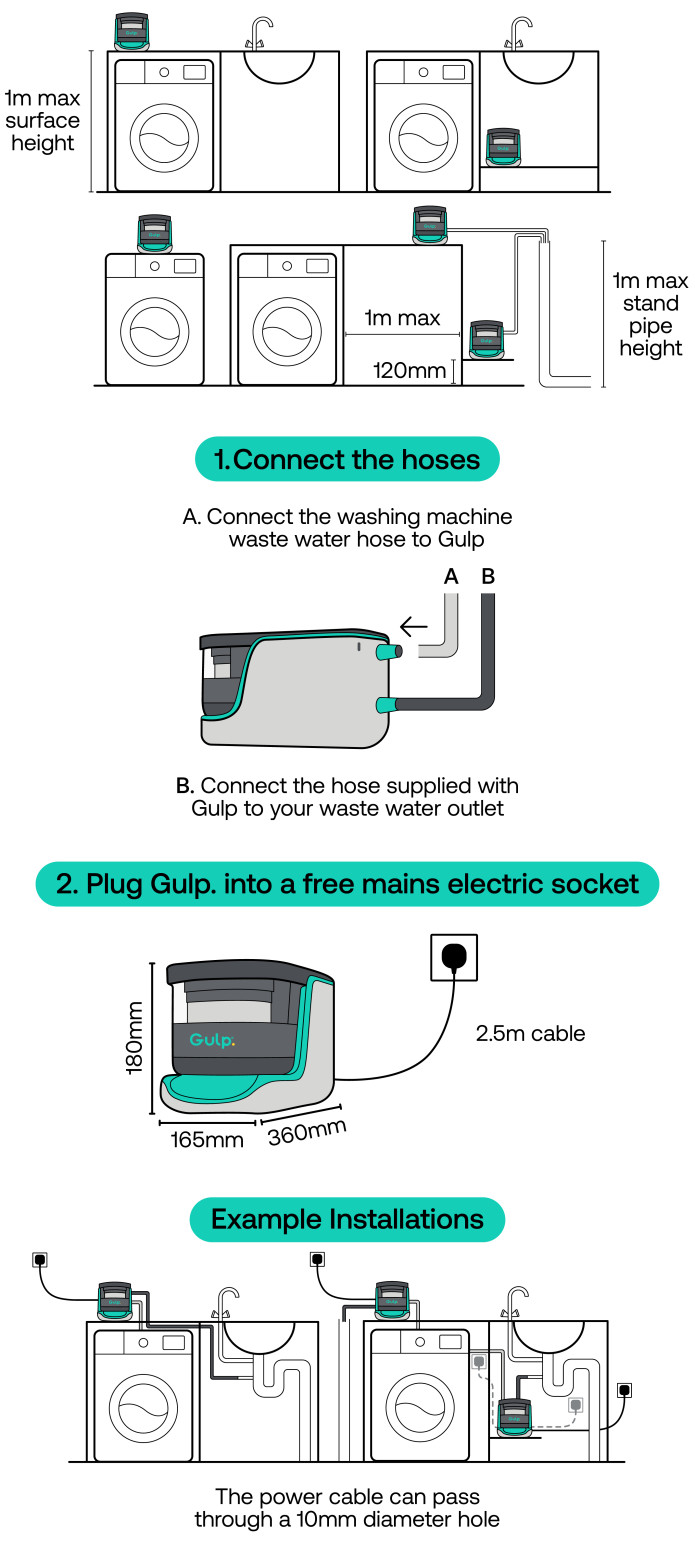

Gulp is versatile and can be positioned conveniently above or at the side of your washing machine.

Gulp works with all European style washing machines and is also suitable for Australasia.

Please see the below diagram showing how Gulp can be installed. Before pledging please check that you can:

- Access the wastewater outlet hose at the back of your washing machine.

- Have space to position Gulp.

- Can access mains electricity to plug Gulp into its own socket.

Note: Outlet hose and power supply with regional plug are both provided (not shown above)

We have spent years developing Gulp to ensure it works effectively and is built to last. Unlike other microplastic filters, Gulp’s unique self-cleaning technology means there are no disposable filters or parts required throughout the product life cycle. We have three granted patents and a further five pending.

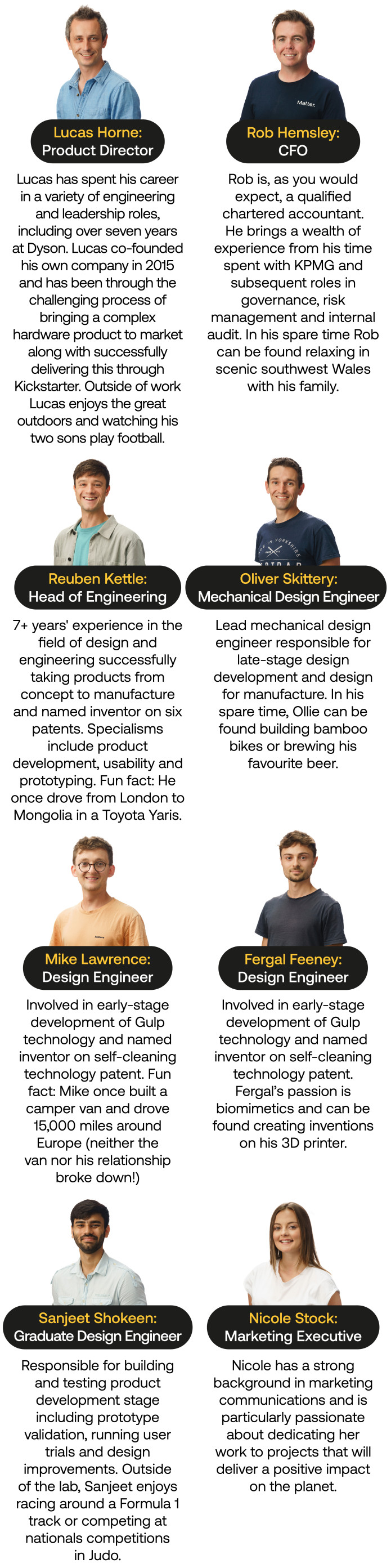

At Matter, we use a robust engineering development process to monitor our technology readiness level (TRL) with gated milestones to ensure that our technology has been rigorously tested and is ready for production.

We have developed hundreds of prototypes making iterative improvements to ensure that Gulp works as expected and meets our high-quality and reliability standards, along with sourcing the best and most reliable components to ensure the design can stand up to the test of time.

We have put a significant amount of effort into the design so that at end of life Gulp can be easily disassembled and recycled. This is in line with Cradle to Cradle principles – an additional certification that we will be applying for to ensure that Gulp is circular and responsibly made.

We have tested key Gulp components simulating hundreds of hours of use to ensure that Gulp keeps working as intended. We have selected high-quality brushless pumps that can withstand the harsh working conditions of washing machine wastewater and have extensively tested them on our in-house test rigs.

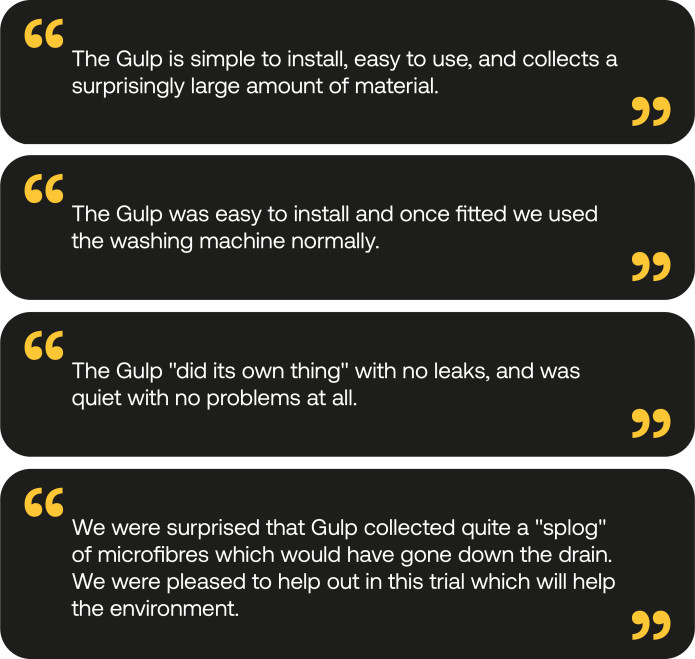

Gulp has been put through its paces in user trials with prototypes working in real-world environments for months on end. This is a vital part of the development process to flag any unforeseen problems not identified in the lab, along with receiving user feedback to improve the product interaction and user experience.

We are extremely proud of our Gulp technology that captures microplastics from laundry and stops it from polluting our oceans. But our work doesn’t stop there…

Our mission is to find solutions for this material to be reused so we can fully close the loop on microplastic. Recycling microplastic captured from our products is the next step, which is why we are leading a number of research projects using the microfibres sent to us to find sustainable solutions for recycling microfibres from our laundry.

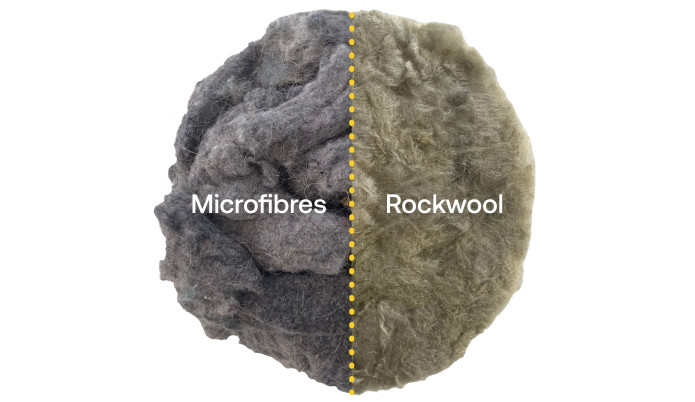

(1) Insulation properties of microfibres

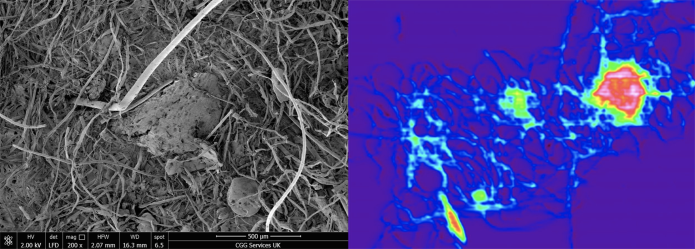

Findings from our latest research confirm the suitability of compressed microfibres as a replacement for insulation panels.

(2) Micropollutant analysis

We have successfully completed a project with our highly respected university partners to characterize micropollutants and contaminants, including microplastics and synthetic fibres, captured by domestic and industrial filters.

The analysis workflow proved to be highly effective at identifying and characterizing materials within complex mixed samples. This approach can be scaled to quantify micropollutants and contaminants in large volumes and contribute to the UK government’s 25-year environmental plan to achieve zero avoidable plastic waste by 2042, and zero avoidable waste by 2050.

Our mission is to continue R&D into the reuse of microfibres to find the most sustainable solutions possible. The support from our Kickstarter campaign will enable us to accelerate our research and continue to explore new innovative solutions for the reuse of microfibres.

Gulp’s journey started when Adam, a keen scuba diver and engineer working in product innovation at Dyson, attended a series of talks organised by conservation groups in Bristol during the summer of 2017. The talks left Adam feeling shocked at the colossal environmental damage being caused by microplastic pollution and what little was being done about it. It was here Adam decided he wanted to use his engineering skills to tackle microplastic pollution and this was where it all began for Gulp.

In July 2017, Adam left his job and started up his own business – a design consultancy called ‘Inheriting Earth’. He then put a pitch together and won a £250 ‘Will It Work?’ grant from the Prince’s Trust. With this money he built a rig using a bucket, wood and an old washing machine that he’d taken apart.

Adam winning the Prince’s Trust ‘will it work’ grant and working from a garden shed building his first prototype

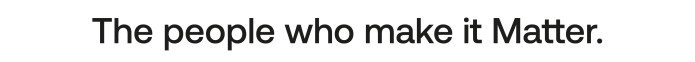

Four years later, Matter has 19 employees and counting. We operate out of a warehouse in Bristol with an open plan office and R&D facility and share the same core mission to make a positive impact on our planet.

On a mission to change our relationship with water and the environment, Adam set-up Matter to provide solutions to the colossal challenge of microplastic pollution.

A trained mechanical engineer, Adam worked on gas turbines at GE before moving to Dyson, where he worked in New Product Innovation. He was awarded Innovate UK’s Innovator of the Year in 2018 and 2019 and represented the UK at the G7 Summit in Canada.

Since founding the company in 2017, Adam has been using his skills and experience to create a retrofit filter solution for domestic washing machines to prevent microplastics from clothing entering the water system.

The Matter Team

We are a young company that was founded on one mission – to stop microplastic pollution. As we progress from the research and development stage to taking our product to market, it is crucial that we build a strong following in the early launch stages to enable us to make as big of an impact as possible.

Indiegogo and your support can help us raise awareness of the microplastic pollution problem as well as provide us with a platform to showcase our solution – Gulp.

UK Backers

There will be no tax or import duty to pay. Simply select your reward and the UK shipping option.

Outside the UK

Please select your applicable country or region to see shipping rates. Recipients will be responsible for costs associated with import taxes, customs duties, or fees levied by the destination country. These charges will be collected at the time of the delivery by the carrier. Please contact your local customs office for more information. If you choose not to pay these upon delivery of your order, the package may be considered abandoned or returned to the UK. Under these circumstances, we cannot consider requests for replacement or refunds.

We choose to work with businesses across our supply chain that demonstrate good and sustainable practices within the environments and communities in which they operate. We searched far and wide for suitable manufacturing partners for Gulp.

We are very pleased to announce that the search paid off and we have selected a UK manufacturer based in Birmingham where the major product assembly will be conducted. They are a family-owned business with over 60 years of experience in injection moulding and product assembly. They are ISO 14001 certified for environmental management and can support Gulp in achieving C2C (Cradle to Cradle) certification. They have the important skills we require in the assembly of pressure systems and a history of supplying high-quality components to the automotive industry to ensure that Gulp goes together and stays together!

Gulp founder Adam root visiting our local manufacturing facility in Birmingham

A few components will be imported but we are keeping these to a minimum and even the electronics will be manufactured in the UK. We are very proud of selecting a UK manufacturer and producing Gulp onshore, supporting the local economy.

Sustainability is in our DNA. It’s why Matter exists

We are working towards certifications for both our business practice as a company through BCorp and our products through Cradle to Cradle. Through our partnerships we want to work with businesses that prioritise the environment and communities in which they work.

Cradle to Cradle Certified assesses the safety, circularity and responsibility of materials and products across five categories of sustainability performance – material health, product circularity, clean air and climate protection, water and soil stewardship and social fairness and we aim to achieve this certification before Gulp ships to you.

Did you reserve a Gulp before we were live on Indiegogo?

If you did then please message us and we will send you the secret perk link to redeem your Gulp.

Firstly, thanks so much for taking the time to read about Gulp. This is the first product we have launched, so it means a lot to know that people are as interested and excited about this product as we are!

We built Gulp for one simple reason: to stop microplastic pollution from laundry. We simply can’t achieve this at the scale required without a community of supporters that are willing to be part of the solution. With your backing, we can make a huge impact for the good of our planet, raise more awareness of the microplastic problem from laundry and demonstrate this problem can be tackled.

Risks and challenges

We have worked on developing Gulp for over 5 years and have assembled a team of experts in research, engineering, and design for mass manufacture to ensure that we are on top of the major issues and have contingency plans in place.

One of the biggest challenges for a product of Gulp’s nature is the supply chain and ensuring a quality manufacturing partner. On that note we have selected a highly respected UK manufacturing partner only 1hr 30 min from our facility so we can quickly visit, and troubleshoot on-site, as necessary. This compared to visiting a manufacturing facility thousands of miles away is a significant advantage to reduce risk and ensure we stick to our plans as much as possible.

We have been working with our manufacturing partner for over 9 months on the final design and design for mass manufacture and are confident that we have a high-quality partner who can deliver to our standards. Likewise, we run an extensive project risk register that tracks risk on a weekly basis and all are now at a sufficiently low enough level to begin the manufacturing phases. All being said we understand things may arise that are unexpected or outside our control, in the event that this does happen we will always be upfront and transparent with regular updates until your Gulp is shipped and is safely in your hands.