No marketing tricks. $299 for an automatic watch + skeleton movement + new time-telling system

No fancy story. No elaborate history. No marketing tricks.

We’re just three guys giving it our best.

Amazing quality for a great price, featuring a skeleton movement, mind-blowing new time-telling method, diamond-cut index, both side sapphire crystal, extra slim design and much more!

JKJinno: Who are we?

JKJinno is a microbrand founded by three young men: Jason, Ken, and Jack. Each one is a seasoned expert in the field of watchmaking. They came together with the goal of breaking through the price to value dilemma in order to create luxurious and affordable watches for everyone to enjoy.

The Industry

In our rapidly globalising world, choice resources and quality materials are abundant and accessible. Worldwide shipping has enabled almost anyone and everyone to get their hands on things that don’t even exist in their regions or countries. In such a case, you’d expect products to be cheaper and better, right?

The truth is reality likes to subvert our ideals. Good products come with expensive price tags and cheap ones don’t reach the bar in the quality department. Why is this? The reason is simple but crucial – balancing every aspect of a product is harder than it looks.

Problem 1: The Execution of the design

Visuals are one of the most pivotal factors of a watch and its brand. It’s the first most impressionable hook for audiences and clientele alike. This is especially true for microbrands that have no preexisting support to lean on. Hence, the scramble for a top notch designer. But relying solely on dazzling looks is a short term solution only. Getting your hands on a master design does not guarantee success. The sketch could be brilliant and perfect on paper. In production, however, what often ends up happening is only 60% is achievable while the other 40% needs adjustment. This is a problem that even big brands face. Microbrands need to consider not only the visual but also the compatibility with the rest of the product.

Solution: The Design Master – Jason Chan

Jason, our powerhouse designer, single handedly established and affirmed his place in the watch industry through his very first brand JW Watch in 2017. His designs are grand and innovative, garnering a following that keeps his iconic models JW-01 and JW-02 out of stock to this day. He continued to hone his skills by joining the Behrens Original team for several of their watches. Learning from the best, Jason gained vital experience and insight into working with more high quality modules. He took that knowledge and incorporated it into his designs. His follow up brand, LORESUM, was created last year and signalled a new peak in his career with its success. Inspired by a railway map, the all new time-telling module was testament to his talent and maturity in unique design and reliable module. With such a presence on JKJinno’s design team, our watch is guaranteed to not only be aesthetically pleasing but capable as well.

Problem 2: The unreliable module

The biggest components of a watch are the things hidden beneath the surface. Whether it be the module, the movement, or the individual gears, these parts do all the work telling time. In recent years, a trend to reinvent the traditional way of telling time has resulted in an influx of new modules. They’re impressive and eye-catching, but not many are as durable as they used to be.

Solution: The Engineering Master – Ken Chan

Ken is the engineering mastermind behind all the remarkable modules of Behrens Original watches. Some notable ones include the rotary module, apolar moon cycle module and the earth/mars dual time-telling module. As a passionate engineer, Ken involves himself in every detail of his creations, going from the drawing board to the materials, to the turning force adjustments and gear calculations, too. This dedication resulted in some of the most stable and reliable modules to ever be wrapped around your wrist.

Problem 3: Expensive custom made parts

Once a design is set, the brand owner must find a factory to produce the parts. This sounds like an easy task given the abundance of factories nowadays, but the choices can be limited by the gap between price and value. Cheap factories provide lower quality. The next step up, ready-made parts, have better quality and can help cut costs; but with non-standard designs, some parts need to be custom ordered. In these cases, microbrands often can’t reach the MOQ (minimum order quantity) needed to justify custom made mouldings. Because of these issues, microbrands often end up ordering parts from several different places at once, incurring a lot of unwanted fees.

If a microbrand insists on pursuing the best quality in each area, the cost of the product would skyrocket. It would lose what we believe to be the greatest appeal of microbrands: affordability.

Solution: The Factory master – Jack Lin

We hold an advantage as we produce most of our parts in-house, but costs can still rise for various reasons. This is where our factory master, Jack, comes in. Thanks to his knowledge and experience, JKJinno is able to create watches at the factory cost with the raw materials imported at factory price and outsourcing left to a minimum. These two components alone reduce costs drastically. As original designs, our watches require the manufacturing of some non-standard parts. However, instead of defaulting to the traditional moulding method, we use a CNC (Computer Numerical Control) machine that makes the parts to order. This method is more precise and accurate. It also waives the MOQ and massive moulding fees that many factories would require. In this way, Jack successfully decreased the standard costs for producing a luxury mechanical watch and customers only pay for the cost of the actual parts. This is a win-win situation.

Skeleton Movement

As you may have guessed, a skeleton movement refers to a type of watch movement that exposes all of its mechanics for the eye to see. The beauty lies in its ability to display the full glory of a mechanical watch. Whether it be the gears grinding, the spring barrels contracting, or just the way every part fits and works together, many who love it always look for more. Skeleton movements are easily recognized by their unique top plate patterns which are highly connected to a watch’s stability. Due to its delicacy, few microbrands can afford to change or adjust the look.

Here at JKJinno, we are proud to present a modified skeleton movement exclusive to our watches. We managed to source the very reliable movement 7 series from an old friend of ours, the HZ factory. Through them, we gained the freedom to explore and create without having to compromise the reliability of the watch as a whole.

The JKJ01 uses the HZ7570 movement which contains 27 jewels and boasts a frequency of 4Hz (28,800 A/h). It comes with automatic winding, sweep second movement, and a power reserve that holds up to 80 hours. This means if you take your watch off for the weekend, it will still be running when you put it back on the following Monday.

Innovative Time Telling

If you’re bored of looking at the typical hour and minute hand ticking away your time, then you’ve come to the right place. Jason has a long record of designing new and stimulating ways to tell time and this time was no different. JKJ01’s time-telling module was inspired by the beauty of its own skeleton movement. The idea was to extend the movement’s appeal to the entire watch, creating an elegant, unique, and harmonious timepiece like no other.

Our watch features a grand total of 3 different hands: a traditional hand and two disc ‘hands’. The familiar polished dauphine hand points to the minutes running along the outer rim of the watch. Beneath it is the thin, sapphire hour disc. This disc was purposely made transparent to display the captivating skeleton movement hard at work. Last but not least is the black second disc snuggled in the bottom left corner of the watch. Small but mighty, this ‘hand’ rotates one full cycle per minute. The exact hour, minute, and second is marked by three separate indicators filled with Swiss Super-LumiNova® BGW9. The dauphine hand tells the minutes, the white nook under the JKJinno logo illuminates the hour, and the thin, white marker above the second disc indicates the seconds.

Diamond Cutting Reflective Index

The diamond cutting index is a newly invented method of index making. Rather than getting creative with the font and shape of the numbers, this method gets up close and personal with their texture. To create something unique and pleasing to the eye, the index was put to a diamond cutter and cut 20 times in two different directions. This creates a surface of many grooves and angles. When light shines on the watch, a natural rainbow of colours reflects off the grooves giving the index a refreshing new look you won’t find elsewhere.

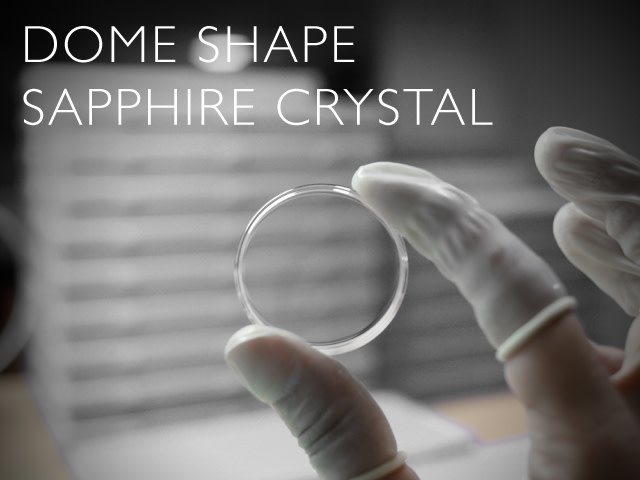

Sapphire

JKJinno insists on giving you the best quality we can offer. Our watches are capped with sapphire crystal on both the front and the back. This crystal has a remarkable hardness of 9 on the Mohs scale. This means it is highly scratch resistant and most suitable for daily wear.

We go the extra mile when we can and on the front of our watches, the sapphire crystal is dome shaped to give them an ultra slim appearance. This is not an easy feat. Raw sapphire comes in 5mm thick pieces that need to be crafted into a 4.2mm dome. Taking into account the hardness of the material, this is a costly and time consuming process with a low yield rate.

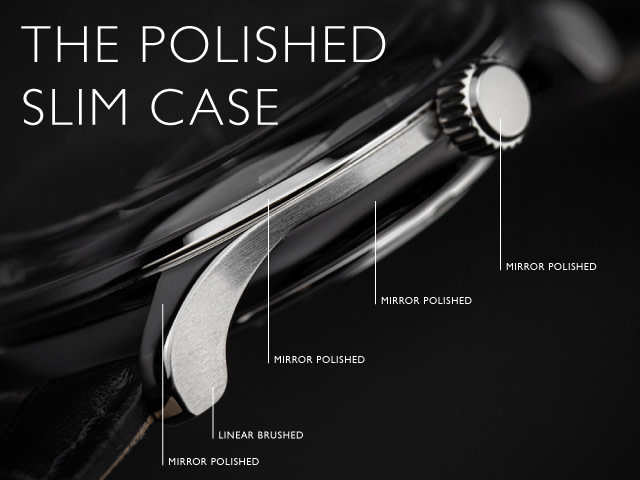

316L Stainless Steel Extra Slim Case

Combining both our design and engineering expertise, we were able to create an extra slim case for our watches even with the mechanical movement. Excluding the lugs and the front dome sapphire crystal, the JKJ01 measures a total of 6.7mm in thickness. Such a slim case design can only be found on luxury watches because of the high engineering and polishing standards needed for it.

To achieve the best results, we use multi-polishing techniques to finish our watch cases. The bezel, back and front side of the lug use a mirror finishing where the rest of the watch is polished with vertical and circular brushes. The contrast between the two techniques enhances the dimension of our watches. The process is labour intensive and slow, but the end product is definitely worth it.

One of Ken Chan’s most noteworthy contributions to the JKJ01 was his active participation in greatly reducing the bulk of the movement (which accounts for most of a mechanical watches height and thickness). He successfully recreated the whole top plate without compromising any of the movement’s reliability. Paired with the unique interior structure of the case, this was integral to the slim design and creating the look of a quartz watch.

Luxury Straps with Interchanging Pin

The JKJ01 comes with two different strap options. The standard one is made of high-grade Italian calf leather. This leather is soft but durable. Each strap is crafted with care and lies comfortably against the skin.

The second option is a Milanese mesh band. The beautifully polished, stainless steel mesh gives off a sophisticated vibe and is fitted with a slick, fold-over buckle. The metal emulates the skeleton movement concept better than the leather for those who prefer it. To adjust the length, use a small screwdriver to lift the clamp located at the back of the clasp to unlock it. Slide the clasp to the desired length, matching the groves on the right side of the strap, and push the clamp back into place to lock it.

All of our straps are interchangeable and fitted with a pin on both sides for easy removal. Push, hold, and pivot the pins in the unlock position to remove or restrap. Release once the straps are snapped back into the lugs of the watch. No other tools are necessary.

Accuracy: Being On Time

In the process of fine tuning, modifying, and creating a new watch, accuracy can drop significantly. To keep you on time and uphold our promise for quality, we put each of our watches through a full week of testing before sending them out. This takes place during assembly and a typical testing routine looks like this:

Day 1

The movement is wound to full capacity

5 positions are tested: crown left, crown up, crown down, dial up, dial down

After a 24 hour rest period, the movement is retested in the same 5 positions

Day 3

The watch is assembled and put into an auto-winding machine

In its fully wound state, the watch is tested like the movement in 5 positions

The watch is set aside for a 24 hour rest period

Day 5

Day 3 procedures are repeated

Day 7

The watch is wound and tested one last time before packaging

This is not an industry standard. Most companies will only test their watches in 3 positions. Here at JKJinno, we like to keep our accuracy within -20 to +20 seconds/day. That means the 2 extra position testings are necessary. Even our design samples were put through an additional on-wrist testing period of 9 months before launch.

This is proof of our dedication. We go the extra mile for you, to guarantee that quality, accuracy, and perfection is sent to your doorstep.

Price

JKJinno’s main advantage is the control we have over our own assembly line. As mentioned before, Jack’s prowess in management greatly reduced our outsourcing and helped us get the best price we can offer to you. Not only do we skip over expensive moulding fees but also any extra paid to produce more than we plan to sell (MOQ charges). Our factory keeps track of the best deals on the market and we import raw materials at everyday low prices. Thus, we are proud to give you a starting price of a mere $299 USD with no hidden fees.

Warranty

JKJinno employs watch masters that perform quality checks in our factory every day. They monitor and ensure all watches are shipped only after passing through all the procedures necessary. However, in the spirit of caution, a 2-year warranty is included. If our services are needed, rest assured your watches will be well cared for.

Free Shipping Worldwide

We offer free shipping worldwide so don’t hesitate to back our watches!

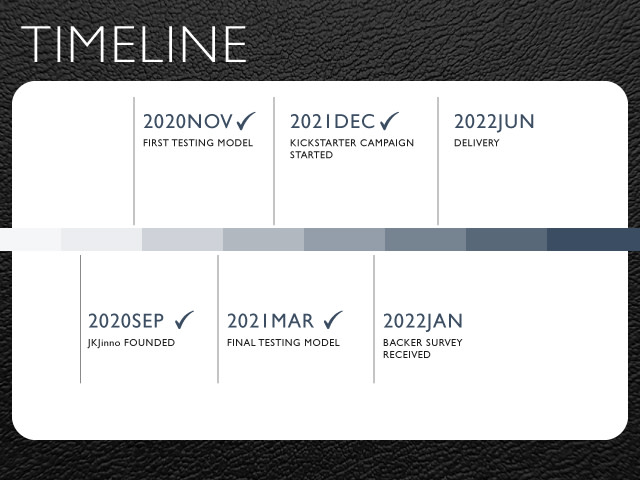

Timeline:

Press release:

We provide a press release and a set of promotional materials for journalists and ambassadors. If you would like to feature us, you can download these resources below:

You are always welcome to contact us for more marketing assistance.

Website: https://jkjinno.com

Email: jkjwatches@gmail.com

Facebook: https://www.facebook.com/jkjinno

Instagram: https://www.instagram.com/jkj.inno

We appreciate all of your support!