A Satisfyingly High-performing Travel Guitar for Finally Reopening US/EU Tourism This Year

Hello, I would like to welcome you with a short sample of the guitar on stage. I hope you enjoy!

My name is Takeshi Suda. I am from Tokyo, Japan and presently visiting Europe for an extended time, touring across countries. I am a guitarist since six years of age, and have B.A. Jazz Composition degree at Berklee College, Boston, MA where I spent six years. I have always been intrigued by the working of the electric guitars, and an enthusiastic hobbyist guitar collector with a track record of ample guitar modification projects throughout my life.

Presently I am asking your kind support for my project designing, building, and making commercially available a new modular travel guitar, first in the US followed by EU and other countries. As the anticipated tourism season is finally a few months ahead of us, I would like to make it available for everyone to take one for vacation. Your kind support definitely helps in ensuring this, without having to wait for the next tourism season in 2023 to travel with this new guitar, as your funding also goes into the production of a how-to DIY the guitar series on YouTube! The campaign has no set goal, but I estimate the minimum fund required for meaningful results may be around USD 20,000 or equivalent.

STORY

It was early January 2020 with the covid-19 looming, when I embarked on the agenda of the year to design and build an original travel guitar I had been brainstorming for years and prove my point. As Croatia began countermeasures against covid-19, I was soon after locked down in a house with a backyard where I start designing and building the guitar only with hand tools including two power tools (drill and jigsaw).

Overcoming the earthquake of the century that shook Zagreb, I successfully completed the first guitar prototype in Sarajevo in June by adding stain/oil finish and the final version of the tremolo system. The completed guitar was made of the neck of a donor guitar, a body made of a piece of oak floorboard, and parts generally available at home centers. By the time it needed electronics in Zagreb, I procured components in one of the local music stores that were partially resumed operations. As at the time of the completion, the guitar featured 4th version body, 6th version tremolo, and 2nd version headpiece.

Having finished and test-driven the guitar, I moved into Belgrade, Serbia where I had seen many jazz buskers in my previous visits. While my only hope was to join the busking jazz musicians, my busking attracted local media where I was featured with the guitar once or twice every month, before I had asked to perform in an International Jazz Day event in late April 2021.

After the performance, The organizer of Nisville offered me with a performance opportunity in their main festival, Nisville Jazz Festival in August 2021. Nisville Jazz Festival is the largest and one of ten best acclaimed jazz festival(s) in Europe. The second prototype of the guitar was on the stage shared with reputable musicians including Gypsy Kings, Stanley Jordan, Gary Husband, Jean-Paul Bourelly, Darryl Jones and Will Calhoun to name a few in the 2021 edition.

The major gigs with the guitar convinced me enough of the new guitar design for me to launch the project to offer the guitar to traveling guitarists and buskers, in order to help them deliver the same great performances as they can with their own guitars, help them capture the greatest musical ideas “in the air” as they immerse in the first-hand inspiration that the great people and nature has to offer on the road, but in more portable way. I strongly believe that from this point on more guitarists embarking on their respective journeys with their own Burger guitars should better write the sequel of this story.

For details, please visit www.burgerguitars.de (PC only, Google sign-in required)

March 9th Update: 75 Pre-order Perks Available for G2G/Dawood Premium Line at 50% or Less!!

I am pleased to announce that an emerging Bosnian woodcrafts marvel, Dawood has agreed today to continuously support this project, by teaming up for the first lot of premium G2G instruments to be pre-ordered on Indiegogo backers.

Dawood has been providing premium eyewear lines featuring wider range of exotic wood materials for descerning client base growing across Europe and beyond, by taking full advantage of rich woodcraft heritage and abundant forestery resources that Herzegovina is historically known for. Collectors come back to Dawood for its stunning craftsmanship with relentless precision and bold designs rendered by the warmth of wood to best translate eye-to-eye messages.

Dawood is led by Damir Bajraktarević, a retired professional guitarist and presently an occassional boutique luthier specialized in solid-body instruments. Damir joined the G2G project from the 2nd prototype to embody the design with his surgical accuracy to withstand the major stage at Nisville.

For details about Dawood, please see: https://www.facebook.com/DawoodStore

The first lot limited edition of 75 custom guitars will be co-branded with G2G and Dawood that will thereafter be designated as the premium G2G tier with double the price tags. We have extensively negotiated to arrive at the common ground, with Dawood’s generous offer and me cutting off everything except for startup needs (since no payable dividends, yet; crowdfunding advantage!) to achieve this amazing offer.

So don’t miss this chance to make the piece of art yours with great pre-order discounts!!

(Note: The discounts also apply for previous pledges. Please wait for email communication to this effect!!)

FEATURES

Fits in a medium backpack, leaving ample room for your mobile rig

While the guitar as assembled is already small and fits in a baritone ukulele case, the disassembled body/neck/tremolo modules can fit in a medium size backpack (40L) possibly with your mobile/busking amplification system. The disassembled body can fit in a 15inch laptop sleeve as found inside of the most of the backpack today. The downsizing was made striking the optimal balance between the playability and mobility.

The guitar features 3-piece modular approach, so the disassembled guitar can ensure the strings free of damage by storing it completely separated from the body and the neck modules, and safer places (additional pockets in a backpack or else). More specifically, the system best saves any damages on the strings inherent to 2-piece systems that are stored with strings attached to both neck and body, highly likely causing very tight bends which we guitarists know means that the string needs to be replaced with a new set.

It is also noteworthy that the assembled guitar can fit in a baritone ukulele gigbag, though a customized gigbag design is highly desired to best accommodate the special design. However, the baritone ukulele case options fairly cancel out “vendor lock-in” situation, allowing for your fun browsing among broader options to carry the instrument in you own style.

About 1.5 minutes to play, sound, and look as great as legendary models thanks to optimal wood-to-wood bond

The neck contour lets you feel exactly the same as the legendary guitar necks, simply because the neck is in fact taken out of the legendary models with minor modifications for the 2nd prototype (and likewise will be for the production models). The neck is assembled onto the body with optimal wood-to-wood bond in the neck pocket that is structurally comparable to conventional bolt-on designs, so that the playability and tonal quality are also optimally comparable to the popular non-travel bolt-on instruments, where you can expect the same output for your input into the instrument. The good size body allows for inspiring design options.

Please take note, the neck in the picture is my own DIY from the donor strat, the production models would be as clean as the body in the picture that is made by Dawood. It’s a contrasting image, highlighting the woodworking excellence of Dawood. The Thumb screw is also made of solid stainless steel machined out of a cylindrical blank, while initially it was an adjustable foot for stools.

Facilitated by patent-pending neck joint, tremolo and headpiece systems, the second version has cut it down to less than 2 minutes.

First prototype Time-to-play: 5min 29sec 29

Second prototype time-to-play: 1min 36sec 59

And believe me, the third and possibly final prototype would cut it even shorter. With your kind support, I am going to challenge to break or get closer to 1 min assembling time.

As you see, the time includes about 30seconds of fine-tuning, that you need anyways with any guitar before you play. So you’re looking to spend a single minute extra compared to conventional non-travels.

Let’s consider what this extra 60 seconds can enable us: greater tone, and playability comparable to any conventional non-travel guitars, that is securely portable in a backpack. Are those things all worth the negligible seconds, or you rather skip the time?

Newly designed tremolo specifically for mobile guitars with tuning stability

The tremolo is specifically designed for this three-piece travel guitar configuration to enable the entire tremolo to be readily attached and detached to and from the body, to expedite the assembling and disassembling of the modules, and to offer the same playability as the conventional synchronized tremolo systems. The guitar features a roller bridge that together with the tremolo system greatly helps in keeping the strings in tune.

Easy tremolo/hardtail conversion with two screws

The tremolo further allows for tremolo/hardtail conversion with two bolts. Because the tremolo lever is removed with a whammy bar and counterweighting springs, no tremolo component will be left unattached from the guitar to achieve a cleaner hardtail conversion only with a firmly fixed base plate left on the body, and thus without any cluttering noise coming out of unloaded springs or an anchor plate. Unlike the “quasi-hardtail” configuration with only a whammy bar detached from a synchronized tremolo, the window-shaped saddle is mounted directly on the body for hardtail configuration, eliminating the slight pitch fluctuation of the remaining strings as you bend a string with the quasi-hardtail.

The tremolo configuration of the second prototype:

The hardtail configuration of the second prototype:

As you see, the hardtail configuration is significantly streamlined.

Damage resilient as desired for travel guitars

The mobility design was engineered mostly utilizing conventional guitar parts and components for easier access to replacement parts in case of any damaged part or component on the go. The limited number of custom parts featured on the instruments are streamlined for damage resistance. The headpiece can anchor strings without the string retainer piece in case the retainer is lost. In the worst case scenario of the tremolo system damage, the guitar can be configured as a “hardtail” guitar to get on your stage that you cannot miss.

Design format for DIY enthusiasts to get inspired and achieve great results

A simple design means simple modifications, so that intermediate to advanced DIY hobbyists can be inspired to get on their own modified version of the guitar, with their DIY replacement of components including electronics, pickguard, machine heads, or even neck or body. As the original Burger was built using hand tools only, advanced DIY enthusiasts can also built the instrument from scratch for pleasant results.

For details, please visit www.burgerguitars.de (PC only, Google sign-in required)

DESIGN PHILOSOPHY

Today, we have seen the most of the guitar signal chain, including guitar amps, rack and pedal effects, go virtual inside a computer or a smart device to offer maximal mobility options as required. Meanwhile, the vast majority of the electric guitars have maintained the same dimensions as the legendary instruments that has made the history of popular music, as the guitarists continue to seek inspiration from the historic tonality, playability and appearance of the legendary instruments, preventing the electric guitarists to gain more mobility. This is also partly because the historic electric guitar models and designs have reasonable mobility already, so that the electric guitars today get behind the mobility of the other part of the signal chain becoming increasingly mobile as the digital technology continues to advance. As such, the more mobile guitars desirably offer the same inspirational playability, tonal quality, and the appearance as the legendary instruments, at the same time allowing for enhanced mobility.

The goal of the guitar design is to propose an alternative balance between enhanced and secure mobility and authentic experience of the historic electric guitar models, by a design that is advanced but not extensive, and that is simple but not scanty.

The goal of the project including the design is to engineer the production and commercially offer the products built in the spirit of the design philosophy to those who opt to have it purchased.

It’s a travel guitar, so…

- Use as many conventional parts as possible.

As the nature of traveling instrument, it is always running an inherent risk of damage, no matter how sturdy your flight case/gigbag may be. We want replacement parts more accessible in case of possible damage through rough luggage handling when we travel. My design includes by far less non-conventional parts, keep in mind that the accessible replacement parts can save your gigs as much as very expensive flight cases you might opt to use.

By using more conventional parts, we can also feel home more as we play, and can sound closer to playing on conventional and legendary instruments we all love. The neck of my design for example allows for the most of the neck replacements for bolt-on guitars and some other guitar models (such as ST, TL and SG).

Furthermore, because the guitar features more conventional parts, the guitar will highly likely to be compatible with any newly-released replacement parts for conventional designs. For example, you can highly likely install a newly developed machine heads available for conventional guitars. Or wider options are available for the machine heads to achieve your desired esthetics of your guitar.

- Make it as simple as possible.

While the risk of damage is inevitable as a travel instrument, we are not completely helpless. As a preventive measure against the possible damage, the special parts featured in my design are all streamlined (or simple if you like), and integrated into a rigid single piece of wood or metal that is less likely to get damaged, compared to the other modular travel guitars in the market.

It is a travel guitar, but we want our guitar to feel, sound and be inspirational as close as possible to the conventional and legendary guitars that we all love.

Aside from the conventional parts, the guitar features a three-piece modular approach with a good size body where we can feature various design cues of the guitars that has made the history of electric guitar and music.

In addition, the simplicity allows for more ambitious DIY enthusiasts to enjoy the modification of the instrument, or even embark on building their own travel guitars with the tried-and-true travel guitar format, keeping in mind that I built the guitar only with hand tools including only two power tools (a hand drill and a jigsaw).

For details, please visit www.burgerguitars.de (PC only, Google sign-in required)

KEY INNOVATION

The guitar has two patent-pending innovative inventions (US63/265,783) that work in synergy and altogether enhance your mobility with greater tonal quality and playability, including dually leveraged string replacement system with leveraging tremolo and headpiece, and a neck joint system with an oversized neck pocket.

Special Design Tremolo System with Window-shaped Wooden Saddle: Tremolo/Hardtail Convertible

The modular travel guitars needs their strings loosen or tighten in one way or the other to assemble/disassemble. Some need our manual labor of turning the machine heads, some feature kinds of “snap-on” neck joint mechanism, some are equipped with special lever installed on the heel for the purpose…most of which calls for more complicated parts for the purpose.

To loosen or tighten the strings, my design focuses on the tremolo functionality that by nature does exactly that: loosening and tightening the strings for pitch modulation. This saves any complicated mechanism, at the same time enabling the tremolo system that is less popular among the travel guitars, let alone their modular variant. My tremolo is specifically designed for this purpose, and specifically for the modular travel guitars.

Also, the tremolo lever piece can be removed with two screws to configure a “hardtail” guitar with the revolutionary window-shaped saddle. The resultant “hardtail” guitar does not have any springs or anchor plate left on the guitar, so that you can eliminate the tedious task of removal/reinstallation of conventional synchronized tremolo systems, and inherently possible cluttering noise coming from spring cavity as you would expect on the conventional alternatives.

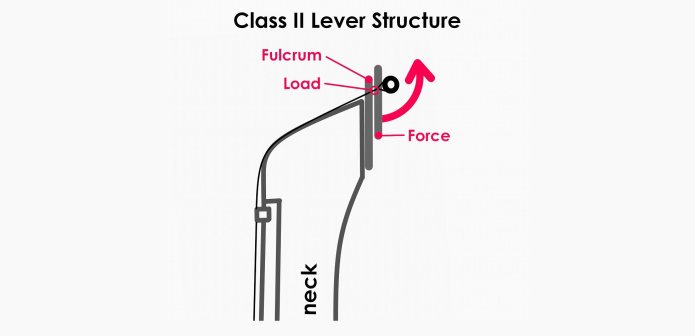

Lever Structure on Headpiece

In addition to the tremolo leverage, the guitar is installed with another leveraging functionality on the other end of the set of strings on the headpiece: neck-end lever structure to further facilitate the removal and reinstallation of the string tension.

These leveraging features synergistically work to let traveling guitarists assemble the instrument as quick as in about 1.5 minutes (as getting accustomed to it), without any hassle, and with much-desired tremolo system on your modular travel guitars!!

Neck Joint System with Oversized Neck Pocket, Neck Clamping Structure, and Conical Fastener Bolt

This feature needs little more technical details that I hope you can cope with.

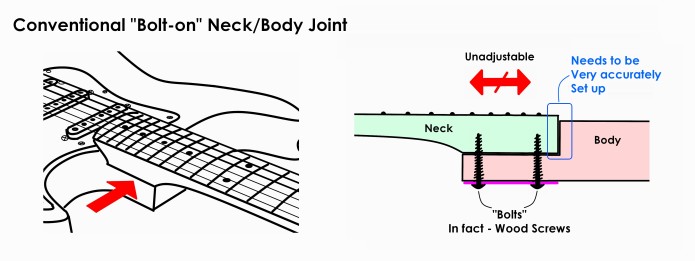

It is essential to keep the tightest wood-to-wood bond at the neck pocket for the conventional non-travel guitars with a bolt-on neck joint. This is simply because the joint enables the hallmark tonal quality of the legendary models that made the history and that every guitarist is familiar with. Meanwhile, the tightest neck pocket contradicts with the easiest assembled modular travel guitars, because the tighter the neck pocket is made, the more difficult to slide in and attach the neck to the body.

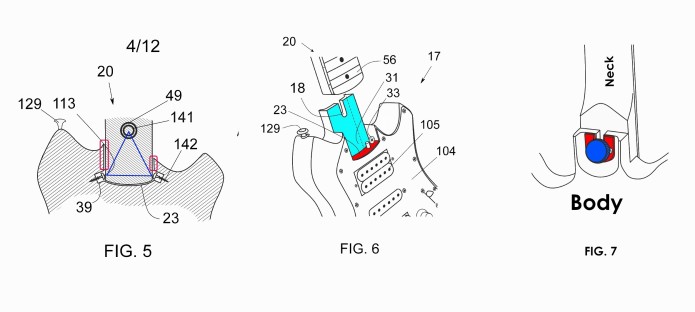

My design provides a solution with an oversized neck pocket to enable both tightest wood-to-wood bond possible and the easiest assembling/disassembling of the modules.

By making the neck pocket wider than the neck, we have to give up the wood-to-wood contact on the sides of the neck (indicated inside the red boxes on Fig. 5), while the neck and the body can be assembled without friction otherwise caused by the sidewalls of the neck and body as the neck is slid into the pocket, except for the last few millimeters of the pocket where there is an adjustable neck clamp mechanism that holds the neck in the calibrated position, that is secured by the thumb screw (indicated in blue on Fig. 7) to a fixed position as the thumb screw features a conical sleeve to fit in a trapezoidal cutout of a horseshoe plate (indicated in red on Fig. 7). The both sides of the clamp mechanism together with the conical sleeve configure the largest triangle (indicated in blue on Fig. 5) available inside the neck pocket.

After all, we lost the wood-to-wood contact at both sides of the neck, as it appears.

However, as you take a close look at the conventional bolt-on neck structure, you’ll notice the wood-to-wood contact at the very tip of the neck (indicaed in red on Fig. 6) is not well-attended, as the fixing screws (bolts) are running in parallel with the contact surface.

Meanwhile, my design includes the string tension is pulling and holding the neck and the body together, and the thumb screw is allowed to move freely in the same direction, so that the wood-to-wood contact of the tip surface in question is 100% ensured. While the wood-to-wood contact of the surface can be perfectly ensured with any well-adjusted traditional bolt-on necks, the contact cannot be guaranteed, while my design is optimized for both frictionless assembling and disassembling, and broader area and tightness of wood-to-wood contact for your best travel alternative.

For details, please visit www.burgerguitars.de (PC only, Google sign-in required)

WHO CAN LOVE G2G BURGER?

Buskers

As the rest of your busking signal chain gets increasingly downsized and powerful with today’s virtual rigs and advanced mobile speakers, your guitar can catch up a little with G2G Burger guitar design. As earlier noted, I specifically designed and made the G2G Burger to be mobile to add to my touring busking arsenal including a flamenco guitar. Thus it needed to be as good as the conventional non-travel guitars while minimizing the luggage to be added. It was born for my busking needs.

Guitarists who double with acoustic/electric on the go

Concert acoustic guitars are bulky, which is not negotiable. So your altenating electric should ideally add the least bulk possible to your gear luggage as you haul or carry around. The G2G Burger does just that, with its tonality, playability, and appearance very much comparable to traditional non-travel instruments. The prototypes has long been traveling with me for a few years already, saving me a lot of luggage handling and fees, and providing the best opportunity available through my TV appearances and major stage performances. It is a proven and materialized benefit of the guitar as it was made for the purpose.

Touring Guitarists

The great playability and great portability have long been in a tradeoff relationship for travelling guitarists. Let’s see how in some scenarios:

If you want to embark on a journey with one of the conventional guitars, you really need to reserve another sheet for your guitar in your flights and buses. Or, you need a sturdy hard case or flight case that can cost more than your guitar, and the bulky case can be subject to additional fee for your check-in luggage.

If you decided to fly with your non-travel guitar in a gigbag, or with a travel guitar, foldable or collapsible or otherwise, featuring intricate mechanisms, you are running a significant risk of your guitar being damaged, or if your guitar features intricate mechanisms with special parts, you could be doomed when the mechanism gets damaged or starts malfunctioning, and cannot find any replacement part you need for repair along the way. All those advanced technologies and mechanisms are surely impressive as are shown off, and may be great for some other purposes, but for travel, they may leave you ending up traveling the remaining legs with an extra burden that does nothing to you.

If you decided to fly with a downsized travel guitar, you might be able to avoid the surcharges, but you’ll be traveling a guitar that does not play, sound, feel, or look anything like your main guitar back home, and so your presentation of your musicality can highly likely be significantly discounted throughout your trip.

Let’s think about it: You might take your downsized only to practice at your hotel, but if you are ever asked to play in the community you are visiting, and you can fully and confidently represent yourself as if you were back home with your main instrument, that would surely make the moments of your long-awaited holidays significantly memorable, for both you and the locals. Your downsized could most possibly miss the chance.

In all of foregoing scenarios, it is too late by the time you finally noticed the problems after leaving home, unless you switch to a G2G Burger along the way.

So, you ideally think ahead and depart with the right guitar.

My design provides the same greatest experience as the legendary guitar models that you might have owned as your main instrument. The guitar is assembled in minimum 1.5 minutes out of your medium (40L) backpack to offer the same great experience as your favorite guitar back home. The backpack is compliant with most of the carry-on luggage requirements, so is your guitar together with your mobile rig in it.

Commuting guitarists

Whether you are a teacher or a student, your G2G Burger can also streamline your shorter trips, or commute. You can relate: your gigbag of your guitar can be a nuisance for the other passengers, especially when its head bumps into the other passengers.

G2G Burger allows you to carry the great conventional guitar experience in a regular backpack, just like the other passengers. You just need about 1.5 extra minutes to assemble or disassemble the guitar after getting in the classroom. Or, even if you don’t have the 1.5 minutes to assemble, G2G Burger as assembled is as small as a baritone ukulele, so it makes easier for you and the other passengers, bumping into the others less.

You, as your main guitar

The design delivers amazingly great playability, feel, sound, and look comparable to conventional non-travel guitars, so G2G Burger can be your favorite workhorse offering what you expect from a historic electric guitar models, as well as enhanced mobility if required.

SHAPES OF THE THINGS TO COME

Because of the aforementioned preference to more traditional designs, travel guitars have always represented a negligible share in the 1/2 billion market historically, while it has always had wide-open opportunity on the horizon to take up some more. As it seems, however, the situation might shift in the coming years.

In 2020, the US saw 16 million new guitarists as Fender reports. In 2021, the guitar sales at Yamano Gakki (Japanese premium guitar outlet) saw 190% increase. Apparently, their instruments need not be mobile, as they are all stayed home amid the ongoing pandemic.

Now that the pandemic is seemingly tapering off by mid 2022, we would highly likely see the tourism jumping back, or possibly surging back. That also includes those 16 million new guitarists. They might leave their instruments to fully enjoy their destinations for change they would have been longing for.

The historical market share outlines the majority consumer decisions: The options presently available mobility instrument lines would let them take “all or nothing” approach, meaning, they would carry their non-travel instruments with additional hassle, or would go on vacation without their instruments with them if the current mobility options would hardly compare to their main instruments back home.

However, what if they have a better electric mobility alternative to best accompany their journeys? My formidable mission in few coming months is to best prepare for those who opt to travel with their instruments, to ensure they would carry the best travel alternatives with them, the best balance between the traditional electric guitar experience and mobility enhancement.

CHALLENGES

The guitar was designed and built during the covid time, dreaming and hoping that we would get back on the road to travel again, but this time with the best companion guitars offered by Guitar2Go Lab.

The guitar has been developed all by me myself, by painstakingly overcoming challenges associated with the covid while I was staying in the least restricted communities in Europe for this purpose. However the guitar is yet a few step behind in making available for the masses.

As the situation is gradually getting back to normal for the next tourism season, I am asking for your kind support to fast-forward the remaining steps through the time to market by June or July 2022 the latest, or otherwise as soon as practicable, is highly desired.

WHY CROWDFUNDING?

As the opportunities to gain meaningful feedbacks are one of the key elements in the development of the instrument but have been restricted by the situation, I would also like to take advantage of the platform to gain the backers’ valuable feedbacks to reflect on the first commercially available product. The mentorship by the backers watching over the product development is highly desired for the maturity of the product, as I transform the guitar built for myself into the one built for traveling instrumentalists in general.

Presently I am the business itself and solely on any task to make it happen. Your kind support will surely allow me to focus more on this project.

The initial hand-drawn design on pizza wrapping paper has been transformed into a series of CAD files based on which the present second iteration is manufactured by local expert and engineer partners.

However so, as the timeframe is limited, I might as well ask for additional partners who can join to work for the project with reasonable remuneration to keep the project on track to achieve the goals on time.

More specifically, your kind support may go into one of the following items:

- Research and development of a tremolo system to be additionally available on the Burger models as an alternative to the presently available system.

- Efforts for commercial availability by July 2022, starting from further complete guitar prototyping for production models to Initial stocking. This may include:

- Design(s) of one or more of Guitar2Go Burger production models, which may include:

Model “Standard Burger” – The finalized first production version of high-performance portability guitar featuring 3-piece modular portability with H-S-H “superstrat” pickup configuration, neck joint system that maximizes the wood-to-wood contact and effortless assembling/disassembling of the neck and body, and specially designed tremolo system and headpiece combo to expedite the assembling/disassembling of the instrument.

“Legend” series, possibly comprising;

Model “ST Burger” – Featuring the design cue and functionality of the most iconic electric guitar featuring three single-coil pickups, flat-top, and 1-ply or 3-ply pickguard,

Model “Tele Burger“ – Featuring the design cue and functionality of the world’s first mass-production guitar featuring two pickups including a lipstick pickup and a single coil pickup,

Model “Les Burger“ – Featuring the design cue and functionality of the world’s first electric guitar invented, featuring arched top and two humbucker pickups, and

Model “Rat Burger“ – Featuring the design and appearance with earthy and DIY-taste warmth, built with components generally available at home centers, with H-S-H “superstrat” pickup configuration.

- Design and development of a padded gigbag.

- Public, customer, labor force and/or contractor relations, including incorporation, branding, product demonstration, marketing, advertisement, customer service, and trade shows.

- Production site setup and/or commissions to contractors, as the case may be.

- Materials, parts, and products to be initially stocked.

- Product and trade certifications and other clericals, including intellectual property, testing, administrative and legal requirements.

- Production of an instructional YouTube video series for DIY travel guitar builders, as well as production of parts and components which may be offered for the audience DIY guitar builders who are in need to facilitate their DIY Burger builds. I would like to have this YouTube channel self-sufficient, which does not look like happening within the time frame.

I SINCERELY WANT TO THANK YOU BEST TO BEST SHARE ITS SUCCESS WITH YOU

Because I have no perk to offer, my (“our” if I would have a team thanks to your support) thank you note would be different discount coupons for your future base-model G2G Burger guitars according to a scheme, starting from 10% and up to 100% for USD20 to USD1,500 (and thereafter you will be offered with a guitar for every USD1,500) or equivalent, in the event of successful campaign.

The sole criteria of campaign success is the sum as indicated (JPY2,000,000) or more, and the specification of the base model is yet to be finalized. I think it is ideal to enable wider customizing options for additional cost on your discount/free base model(s).

All in all, please kindly allow me to communicate about the foregoing details after the completion of the campaign in 30 days.