Prepare for the drive of your life. A compact, high torque driver that’s more than just a tool.

MetMo Driver: Bringing an icon of engineering into the 21st Century

Not since the mid 20th Century have we seen a design like MetMo Driver. A piece of engineering history re-imagined for the modern day. MetMo Driver is both a fidget toy and tool, keeping you satisfied for hours on end either fiddling with it or using it to drive to the centre of the Earth.

Why have we created MetMo Driver?

MetMo Driver is a hybrid of the hand braces of old (the pre-cursors to electric drills) and modern ratchet screwdrivers.

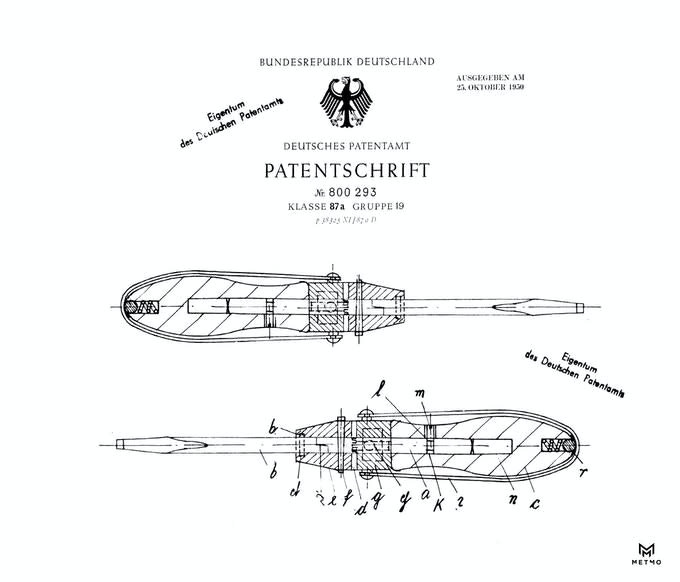

We set out to infuse our signature MetMo satisfaction with one of the most well used tools in existence, the humble screwdriver. We were fascinated by Conrad Baumann’s ratchet driver from the 1950’s and its mesmerising exposed ratchet mechanism, so we set to work to create the most powerful and compact driver in existence and, while we’re at it, inject some MetMo satisfaction at every opportunity.

Who’s it for?

Made for designers, engineers, thinkers, and anyone who wants to just take a moment to focus, relieve stress or just play around. MetMo Driver is both a powerful and versatile tool and amazingly fun to fiddle with!

A powerful tool and the perfect desk toy

Like a Swiss watch, each component interlocks perfectly so you can enjoy the endless motion of MetMo Driver’s moving parts.

MetMo Driver is a tool you won’t want to hide away in your tool box! Designed to be fiddled with, each rotation and click has been meticulously crafted to give you maximum satisfaction, even just sat at your desk.

A satisfying drive

Simply rotating the chuck is huuuuuuugely satisfying. The weight feels reassuring in your hand and you know that if you do ever need to drive something in, MetMo Driver is there for the job.

Driving back in time

Own a part of history as one of the early forms of the ratchet screwdriver, created by Conrad Baumann under the brand name Baumann-Weltrecord. Re-imagined using hardened materials and state of the art machining techniques, Baumann’s vision lives again, driving home the quality and reliability for which his original was known.

With only a handful of originals left in the world and even fewer available for auction, this loving recreation is the best way to own a former icon of industry and keep the story alive for future generations.

We also examined the original and engineered out all of the weak points to make it a useful tool for the 21st Century.

MetMo Driver doesn’t believe in pilots

Sure, we know most jobs can be done with the correct prep and a decent power tool, but there’s something reassuring and oddly satisfying about driving a screw as deep as it will go without the high-pitched squeal of a reluctant drill.

With MetMo Driver featuring Autopilot Tech (totally trademarked), you can drive screws in without the need of a pilot hole.

Kick it into overdrive

This beast can handle everything – from driving in an un-piloted coach bolt to drilling a perfect hole with your spade drill, MetMo Driver is nigh unstoppable. Unlike a standard screwdriver, you can get all of your weight behind the MetMo Driver, just keep on drilling until you reach bedrock. It’s more powerful than some alligators.

MetMo Driver works in the same way as a manual brace, but pocket sized!

Why this design? Why not a modern ratchet screwdriver?

Modern ratchet screwdrivers are built to a cost and made from cheap plastics. We wanted to create something that was a full metal construction and built from materials that would last generations. The Driver’s design lets you put in screws much easier than a standard screwdriver.

We found the original design was hugely satisfying to fiddle with and we wanted to re-create that feeling by combining it with something which looked amazing, so you could even enjoy it at your desk as an excellent piece of engineering (and show it off to your friends 😉 )

We fell in love with the original design by Conrad Baumann and just how versatile it could be. The original was purely a screwdriver, but with standardisation of bits we saw a huge opportunity to turn this concept into one hell of a multi-tool.

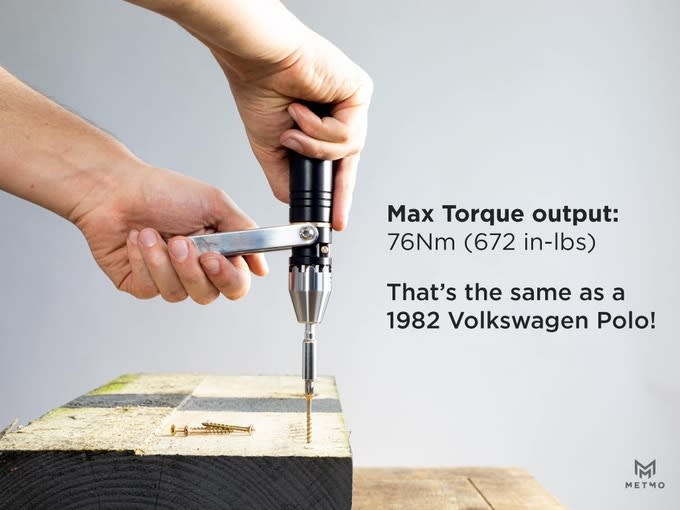

Super high torque screwdriver

With its arm lowered into wrench mode, MetMo driver can deliver over a whopping 70Nm of torque, ensuring you can always drive on home without stopping for gas.

Use with any drive bit

MetMo Driver is compatible with all standard removable Hex drive bits, so you can use it with 1000’s of modern fixtures, including your favourite brands from all over the world. Or use with standard adaptors to make it even more versatile!

Forward and reverse

Easily flick between forward and reverse with a satisfying click. You can also lock out the Driver to turn it into a fully manual driver.

Easy on the wrist

The unique design makes putting in screws manually much easier, placing far less stress on the wrist so you don’t end up with a burning forearm after putting in one screw.

Never slip again

You’ll never strip the head of a screw again, as its unique mechanism allows the handle to remain stationary as you put all of your weight behind the Driver, so it can’t slip and ruin your screws.

Battery free

It’s always handy to have a compact tool in the box for when your battery screwdriver can’t handle that stubborn screw or runs out of battery at the worst time!

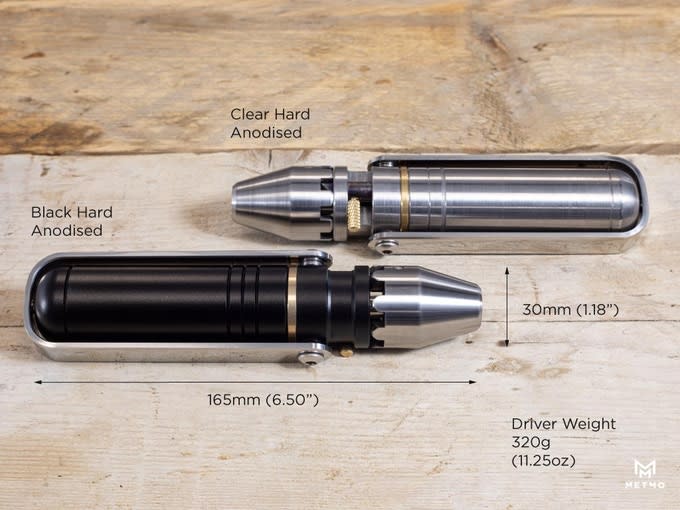

Compact and powerful

Smaller and lighter than normal wood working tools, ideal for any tool bag, backpack, glove box, or even back pocket if you’re doing some serious fixing.

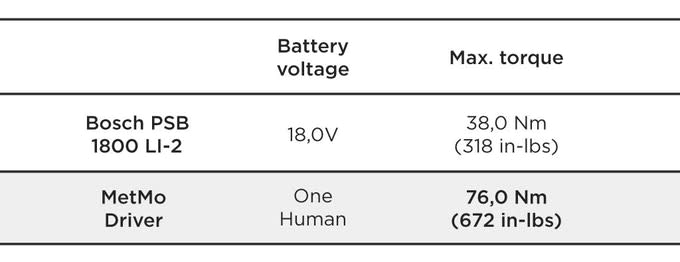

The Torque about town

Winner – MetMo Driver, coming in at 2x the power of a standard power drill

Calculations

We have tested MetMo Driver under very heavy loads ranging from 50-100kg of force.

Equation:

Force 1000N (100kg) x distance from rotational axis 0.076m = 76Nm (672 in-lbs)

The mechanical mechanism makes putting in screws a breeze and will give any battery drill a run for their money, driving in those big screws where electricity fails.

Technical Data

Weight: 320g

Size: 165 (6.5″)mm x 30mm(1.18″) x 43mm(1.70″)

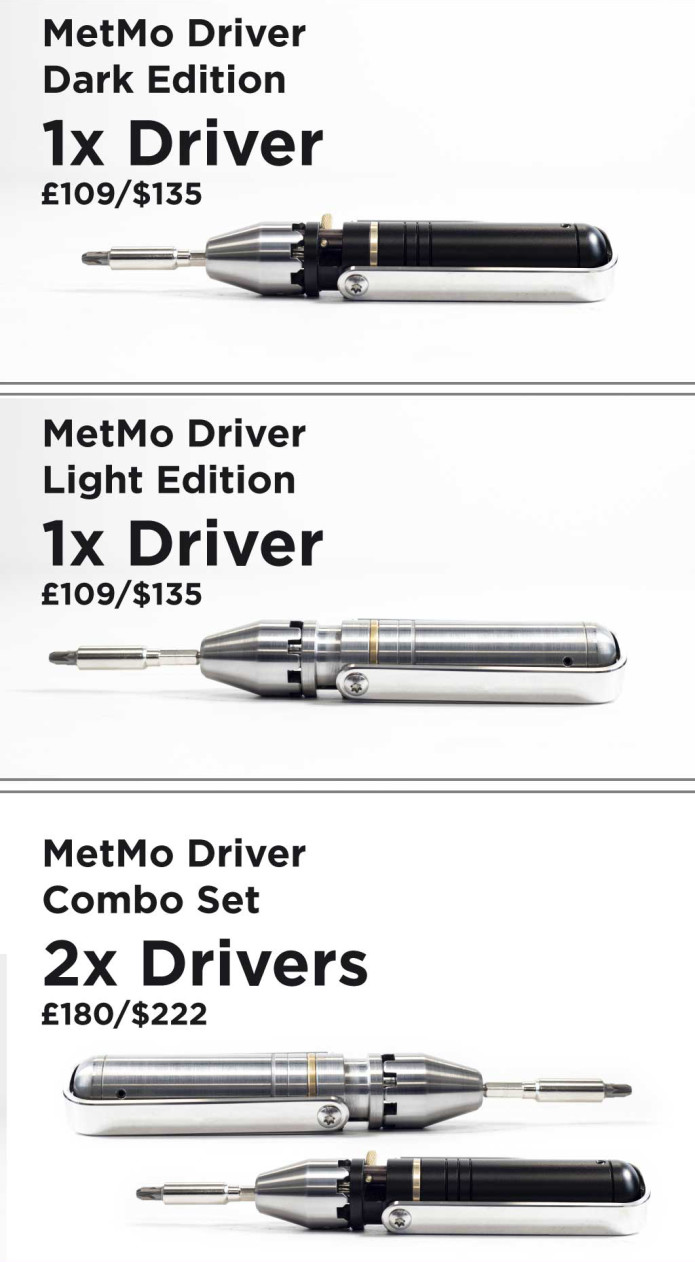

Finish: Heat treated stainless steel, hard anodised (clear or black)

Maximum Torque: 76Nm (672 in-lbs) We can probably go higher than this*

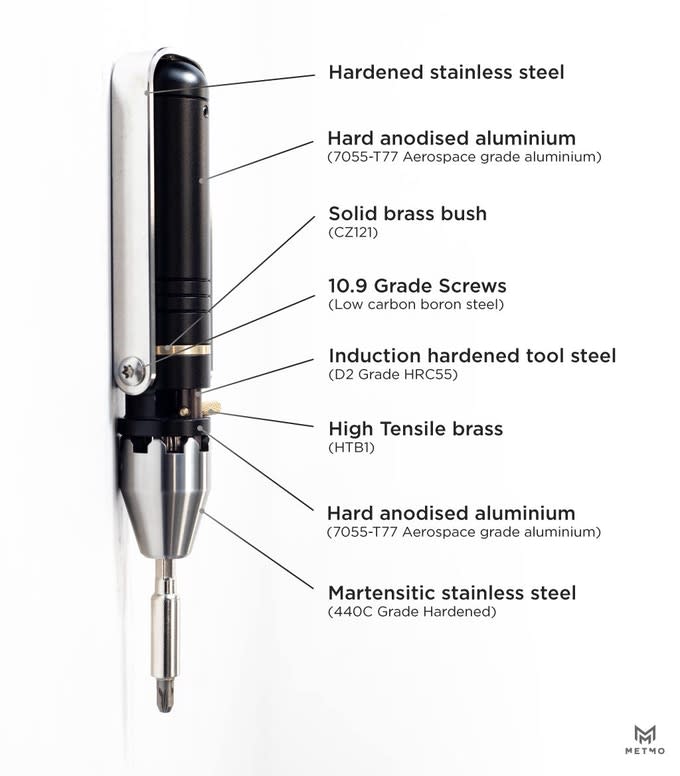

Materials: Hardened Martensitic Stainless Steel grade 440, hardened tool steel, Hard anodized aluminium, Brass, Plate stainless steel and class 10.9 bolts.

Bit Size: 1/4 (6.3mm) Hex drive bits

Magnetic Socket: Yes

MetMo Driver is designed to handle varying loads of large humans and other heavy mammals. *Disclaimer – Not designed for use by reptiles*

What’s MetMo Driver made of?

Safety tests

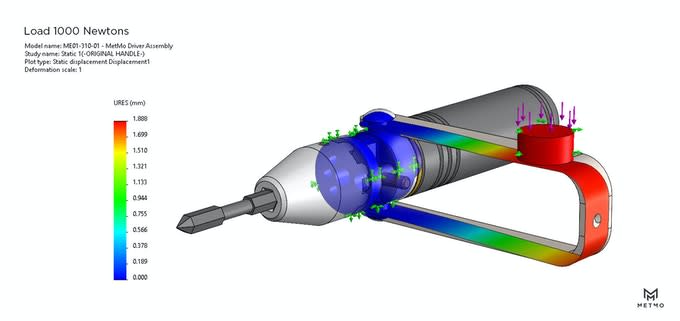

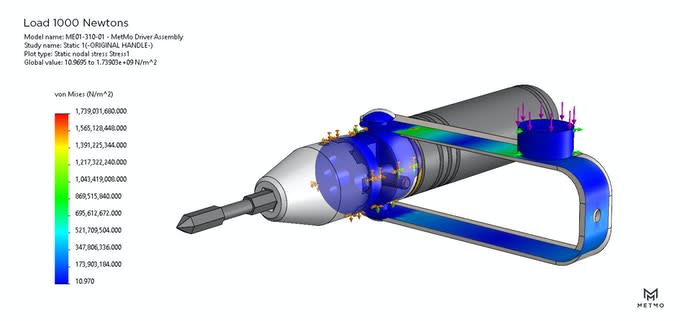

When we started we wanted to be sure that the handle would survive a serious screwing session, so we set to work making sure we tested every component of our new design.

We built a test rig which allowed us to apply 100kg (220lbs) of weight through the handle in a worst case scenario. (Essentially, if you could put all of your weight through two fingers, that’s what was simulated.)

As you can see, it’s pretty difficult to apply this much weight to something, so we feel like this is enough.

We put the fun part of the test in the video below, and it shows the handle deflects, but returns to its original position with no damage.

[Video? vv ]

We ran the sim under a single point heavy load of 100kg and you can see a slight strain in the arm, but nothing that would lead to a breakage. This is an absolute worst case scenario and would require you to put all of your weight through a single finger… kudos to anyone who can manage that!

As you can see, the main body and hardened pin remain completely unstrained by the test.

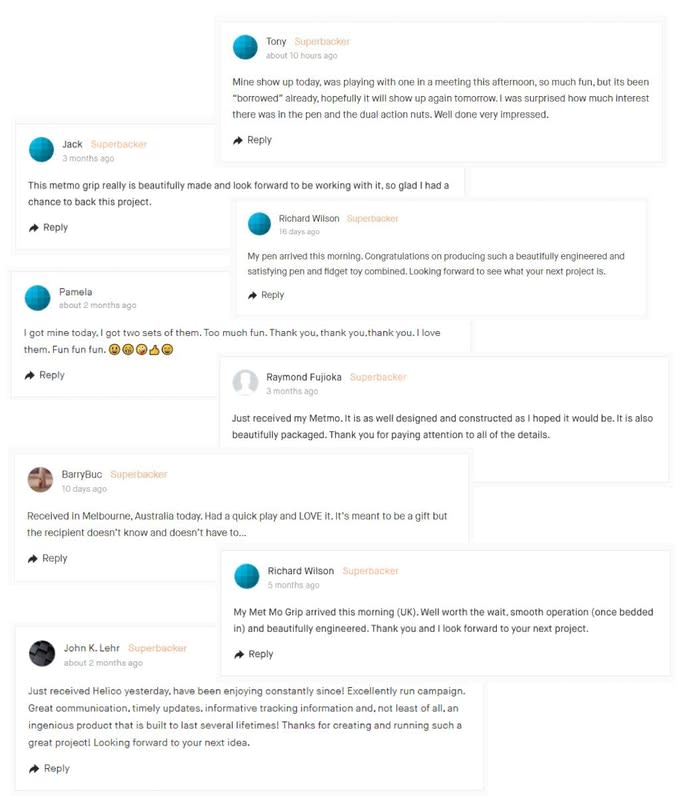

Previous testimonials

This isn’t our first rodeo! We have delivered to over 5,000 backers through some of the hardest times over the last 3 years and with every campaign we get better and better. Here’s what some of our past backers have to say!

Rewards

Add-ons

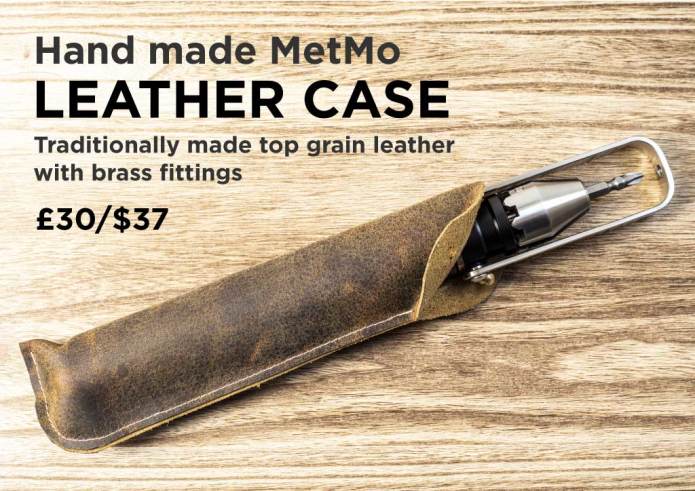

MetMo Driver Pouch

We felt the original was lacking a nice pouch, so we wanted to include this from the get go. Don’t forget to add this on to your reward 🙂

MetMo Driver Expansion Kit

An expansion kit that allows you to go from the standard ¼ (6.35mm) hex to any square socket size, compatible extension arms so you can get into those awkward to reach places and also a ¼ (6.35mm) hex drive to 4.3mm micro hex drive. All of these pieces are interchangeable so if you wanted to use the 4.5” (11.5mm) extension arm with a 10mm square socket adaptor to reach into a godforsaken void, buried deep within your car, you can do just that. Nowhere is off-limits!

We wanted to combine this with a vintage leather case, instead of those big plastic cases these things usually come in. So we went with a classic tool roll style that holds all 13 bits (hopefully that’s not a bad omen) plus 2 spare slots as well as a loop in case you wanted to keep the driver with your adaptors. When fully assembled, you have a modern kit that has a real vintage feel.

Here is the full List of the bits included in the expansion kit;

- ½” (12.5mm) Square short shank

- 3/8” (10mm) Square short shank

- ¼” (6.35) Square short shank

- ½” (12.5mm) Square long shank

- 3/8” (10mm) Square long shank

- ¼” (6.35) Square long shank

- 2.2” (60mm) extension

- 3” (75mm) extension

- 4” (100mm) extension

- 5.9” (150mm) extension

- Micro hex adaptor 1/4″ (6.35mm) to 5/32” (4mm)

So what’s the deal, why does it cost £109?

We always use the best materials we can get our hands on. For this project we’ve used premium metals normally used in the aerospace industry. There are a lot of components in the Driver with each part is individually machined in a laborious low volume production machine, then every part needs to be set up by hand and slowly cut to ensure the fine tolerances are maintained to make sure each part fits together perfectly. This all adds to the time and expense of making each Driver.

Normally screwdrivers are made from one or 2 pieces of low cost metal and plastic that are stamped out and moulded: we wanted to create a piece that was less mass manufactured and more fitting to the Drivers heritage, as well as being top quality to last a lifetime.

MetMo Driver is only produced in small batches and we only deal directly with our backers, this helps to maintain quality and ensure our unique designs last a lifetime.

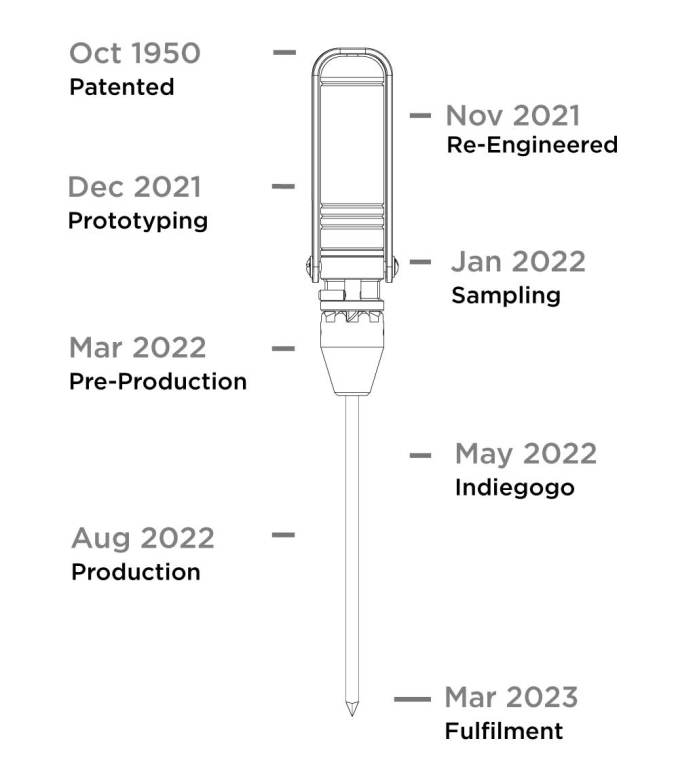

Timeline

Making of the Driver Prototype

Sit back, relax and enjoy this video of the making of the MetMo prototype from scratch, with our master metal worker, Geoff.

We go through every milling, drilling, turning and tapping process to make a driver from raw billets of metal so you can see the amount of work involved in making a driver. Although this one off was made by hand using manual machinery, the production ones will use industrial CNC machinery.

What is MetMo?

MetMo is our philosophy. Metal in Motion. The peak of engineering excellence in industrial, aesthetic and functional design. Precision engineering of cutting-edge quality, delivered to your hands.

MetMo is not about producing low grade products for mass market re-selling. Instead, we focus on low volume ideas that can be interesting and more fun for us all to share our love for engineering and fascination with mechanical design.

Who Are We?

We’re a small team of engineers and friends, banded together through a love for cutting-edge design that we are dedicated to delivering. We’ve made tools and precision instruments of intrigue in the past and deliver them to our backers no matter what problems the world has thrown at us and we’re passionate about continuing to do that with the Driver. We’ve simulated, prototyped and tested, building on previous relationships with manufacturers all over the world, to pull together the best components and techniques.

With each campaign we strive to be better and learn from mistakes at every stage, and this project is no different. Our aim is to make the Driver our best product yet.

This is our 5th kickstarter and we’ve had our ups and downs in the past, but we always put the backers first to ensure we deliver our projects to the level of quality we promise.

We have teamed up with a specialist manufacturer that creates precision tools for brands all over the world and with our existing CNC workshops we have extensive experience to overcome any challenge.

Over the past 3 years our team has grown slightly, to include new engineers and hobbyists. All who share the same love for engineering and design, coming together to work on these projects for the shear fun of creating something new and interesting.

We really feel that the backers we have met along the way have become apart of that team, so please join us and become part of the MetMo-verse!