Better Sheets Means Better Sleep

Naked Sheets:

Made from 100% Eucalyptus. Soft as silk, strong as polyester, cool as linen, warm as wool and as absorbent as cotton.

Available Colours:

Dark Blue + White

Being made from Eucalyptus Lyocell, our sheets are naturally fast-wicking drawing moisture from the body and 50% more breathable than cotton. This keeps you cool at night, preventing night sweats. It’s also naturally anti-bacterial and hypoallergenic which helps prevent odors and improves hygiene.

“Lyocell is composed of nanofibrils — literally very, very small fibers — which are hydrophilic,” a quality that makes the fabric better at absorbing moisture, Bahulkar wrote. “This gives the material a unique moisture absorption ability, which in turn makes [it] breathable, softer, [and] less prone to wrinkles.”

Vasant R. Kothari wrote in Application of Contemporary Fibers in Apparel – Lyocell, “Completely natural, Lyocell offers a unique combination of the most desirable properties of manmade and natural fibres: Soft as silk, strong as polyester, cool as linen, warm as wool and as absorbent as cotton.”

Did you know that your skin works to keep you healthy by discharging up to 1lb of toxins per day? Petrochemical fibers like nylon, polyester, acrylic, acetate or triacetate actually restrict toxin release. You can read more on this at re/make!

Naked Sheets allows the body to breath, detox and regulate body temperature properly!

People are tired of sleeping on stiff sheets. Sure, “Egyptian Cotton” gets softer as you wash it… apparently… but who wants to wash their sheets a bunch of times, wasting a bunch of water, just to make their sheets comfortable? The secret to producing Naked Sheet’s sorbet-soft feel was finding the optimal thread (500) and combining it with finer quality threads. We only use fine yarn of 80s x 60s count. Most bed sheets on the market use 60s x 40s yarn count.

Thanks to The Chemistry of Textile Fibres we were able to dive deeper into what truly makes a softer textile. It’s another reason we chose Eucalyptus Lyocell, because the moisture regain is 13% (as opposed to cotton’s 7.5%) and it transports moisture more effectively. Garments and made-up with Lyocell therefore have a high degree of comfort and are more pleasing to touch.

Three of the most acutely hazardous insecticides, as determined by the World Health Organization, are used in the top 10 cotton mills.

One of them, Aldicarb, “can kill a man with just one drop absorbed through the skin,” says OTA, “yet it is still used in 25 countries and the U.S., where 16 states have reported it in their groundwater.

At present, many of the key cotton-producing countries are under high water stress. Cotton production currently accounts for 2.5% of the world’s arable land (healthy land that’s good for crops).

Whereas the Eucalyptus Tree is fast growing and takes up one-fifth of the land for the same amount of consumer material as cotton

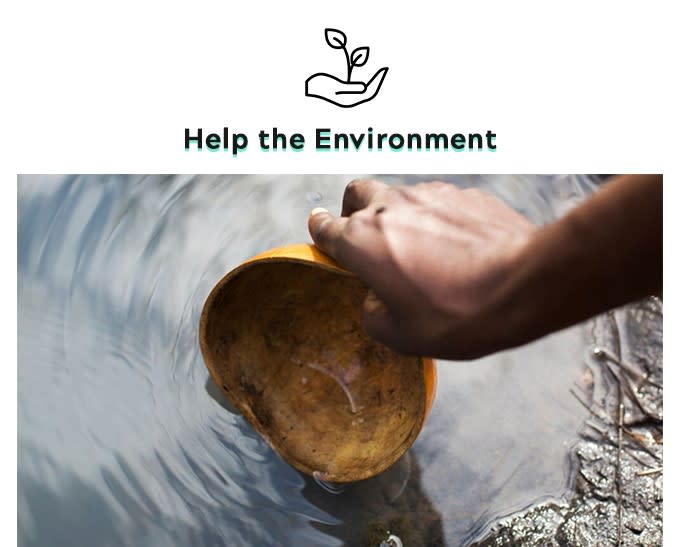

The SAC’s Higg Materials Sustainability Index (Higg MSI) is the apparel industry’s most trusted tool to accurately measure the environmental sustainability impacts of materials.

The Materials Sustainability Index (MSI) is a cradle-to-gate index that evenly weighs environmental impact areas including chemistry, energy and greenhouse gas intensity, water and land intensity and physical waste.

The higher the index is the more sustainable the material is!

Eucalyptus Lyocell is the highest MSI for the best price!

Source: https://apparelcoalition.org/higg-msi/

The eucalyptus used in our sheets are FSC, PEFC, Sustainable Forestry Certified, and OEKO-TEX certified so you can rest assured that your sheets are safe and low impact on the environment.

The MADE IN GREEN label verifies our sheets have been tested for harmful substance processes under environmentally friendly and socially responsible working conditions.

The Made in Green label comes with a QR code that gives you access to information regarding our production facilities in which your Naked Sheets were produced, the stage of production to which the facility belongs and the countries in which our manufacturing took place.

It also verifies our sheets have been tested for harmful substance processes under environmentally friendly and socially responsible working conditions.

We work with like-minded people who go above and beyond to give back to their community and the environment that supports them. That’s why we’ve partnered with the world’s only fibre manufacturer using a zero-emission, closed-loop bleaching process.

Our manufacturer works closely with communities on projects ranging from providing education to children in poverty to women’s empowerment to conserving endangered forests.

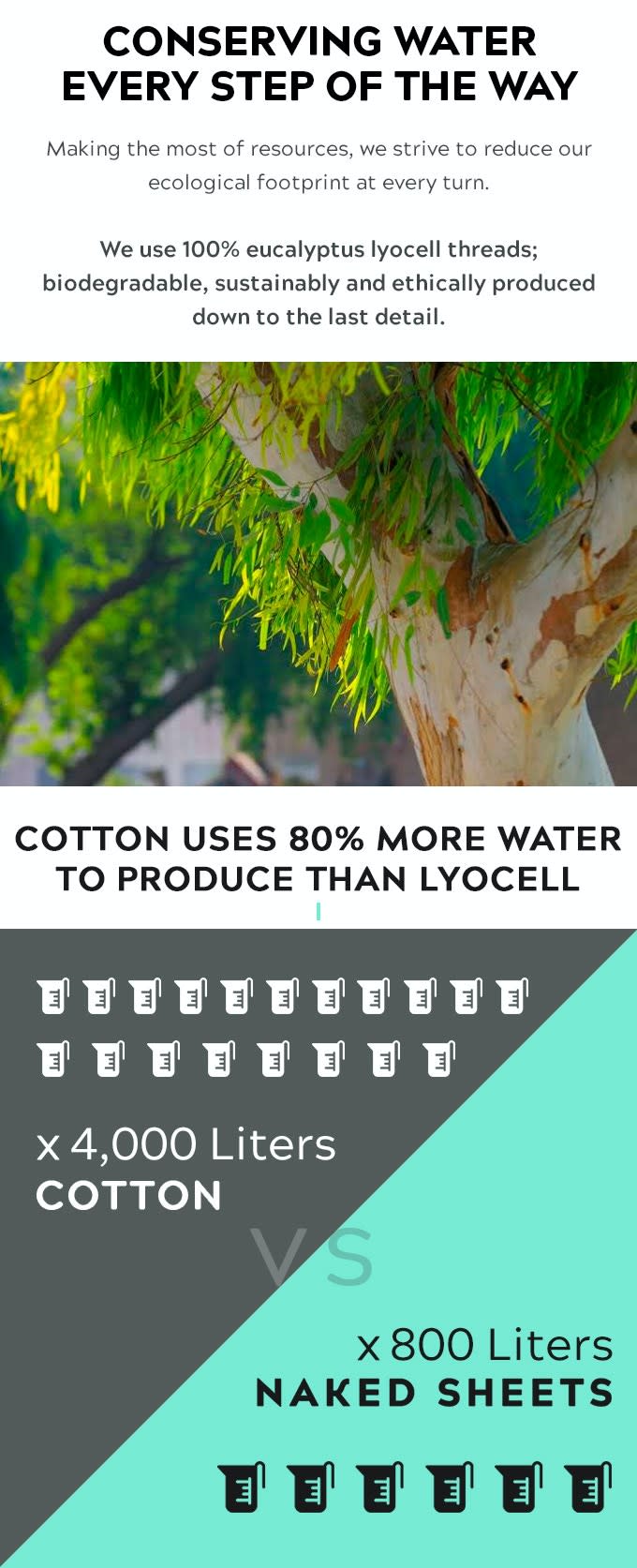

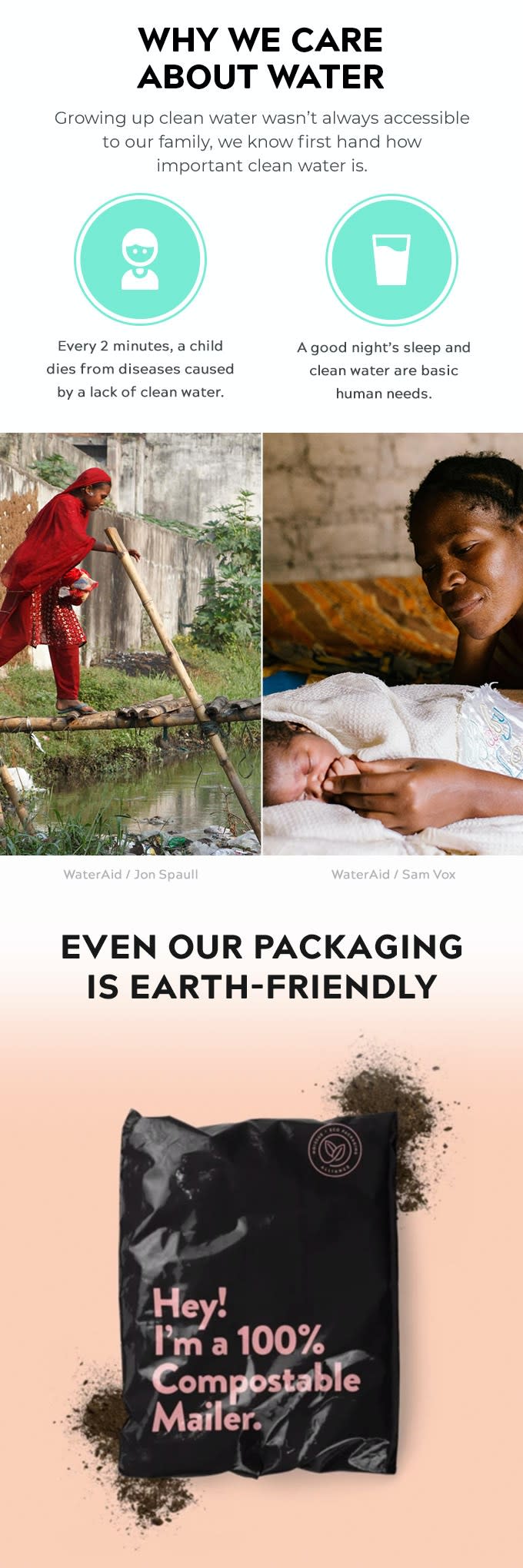

On top of saving a ton (literally) of water during our manufacturing process, we will also be donating 50% of our post-Kickstarter business net profits directly to WaterAid who, since 1981, have helped more than 25.8 million people gain access to clean water and 25.1 million people with reliable toilets.

Today, more than 750-million people live without safe water and 2-billion live without a toilet of their own. These basic services are human rights: everyone on our planet needs them to live healthy, dignified, and productive lives.

WaterAid has teams in 34 countries, changing millions of lives every year with clean water, decent toilets, and good hygiene.

And they’re just getting started!

Just a simple bag made out of the same material as our sheets. We’re proud to deliver Naked Sheets to you in a plant-based 100% home compostable mailer bag! We’re committed to removing plastic from packaging and shipping!