Folding Design | Infinite Work Area | 100s of Materials | Precision & Accuracy | Internal Filtration

Meet Optic—the first portable laser cutting and engraving solution with integrated filtration and infinite work area capabilities. Work with hundreds of materials from your home or office, and enjoy the ultimate flexibility to create anywhere you go.

Press

What Makes Optic Different?

As a creator, your imagination knows no bounds.

But, when you sit down to turn your sketch into a prototype you are weighed down by limited access to tools available in a maker/creator space.

Most desktop laser cutters and engravers are either too expensive, too heavy and cumbersome to work with, or lack the power to create exactly what you want in the time you need it.

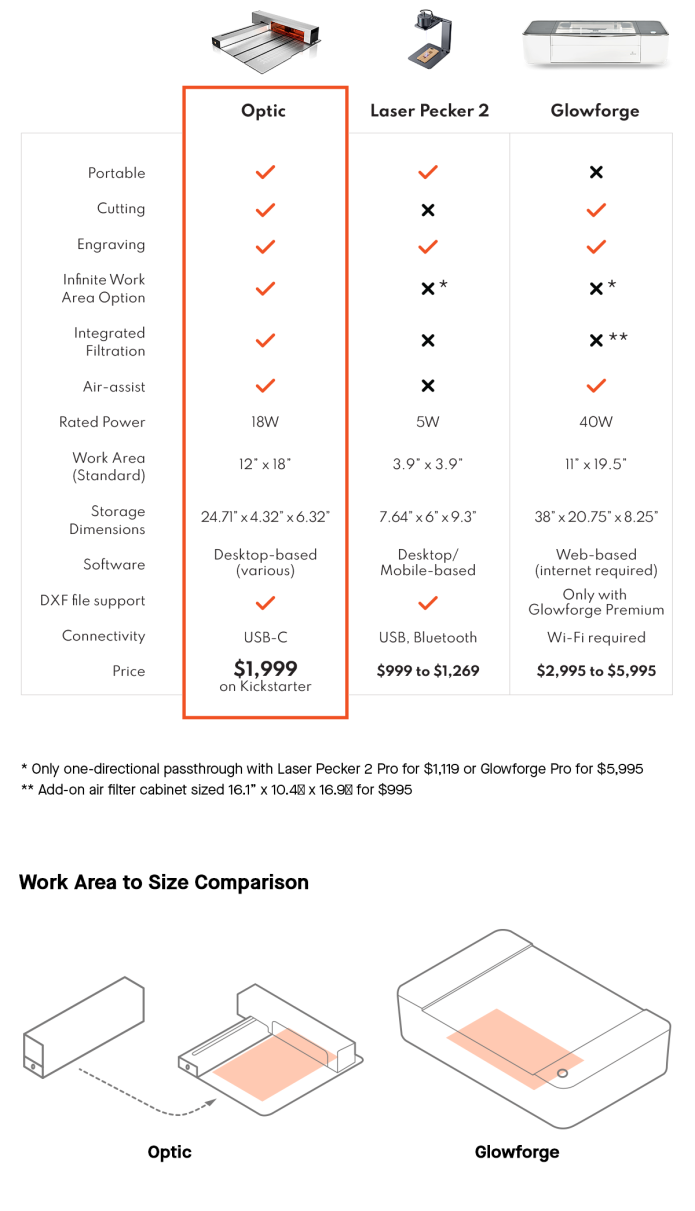

THE OPTIC VS. OTHER TOOLS

THAT’S WHEN WE DECIDED TO CREATE SOMETHING NEW

It’s time to stop letting existing cutting and engraving machines bottleneck our projects.

That’s why we created Optic.

Optic is the future of desktop prototyping—it empowers creators with new possibilities and capabilities to create physical products of all kinds easily with industrial precision and accuracy.

With Optic in your creator arsenal, you enjoy a hassle-free workflow from design to prototype to product.

Features You Can’t Live Without

CREATE WITHOUT LIMITS USING ANY MATERIAL YOU WANT

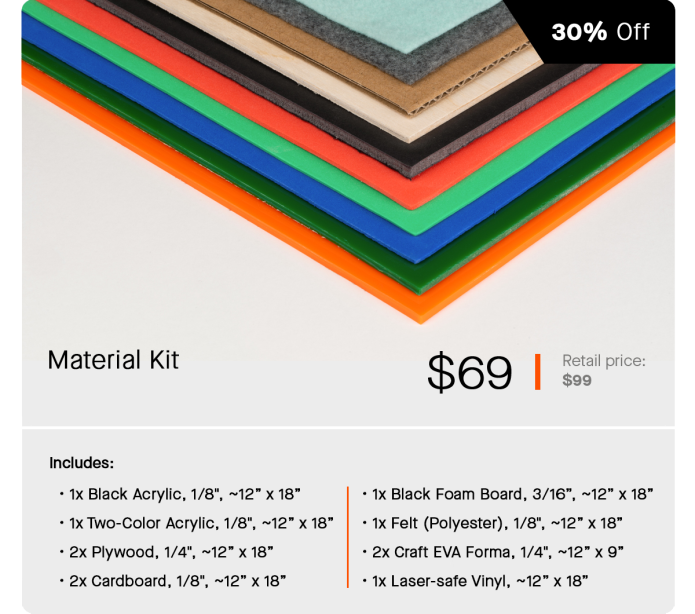

The Optic lets you create with a wide variety of materials including paper, wood, and fabric products as well as specific metals, plastics, and foams.

ENJOY INFINITE WORK AREA CAPABILITIES

USE WHEREVER YOU WANT WITH INTERNAL FILTRATION

The Optic is the only desktop laser cutter with fully integrated filtration. The laser cutter comes with replaceable multi-stage filter cartridges so you can use it wherever and whenever you need to without worrying about permanent exhaust ducts.

FOLD IT UP WHEN YOU’RE DONE

Finished with your project? Just fold up the Optic and put it to the side. No clutter, no chaos—just seamless creativity.

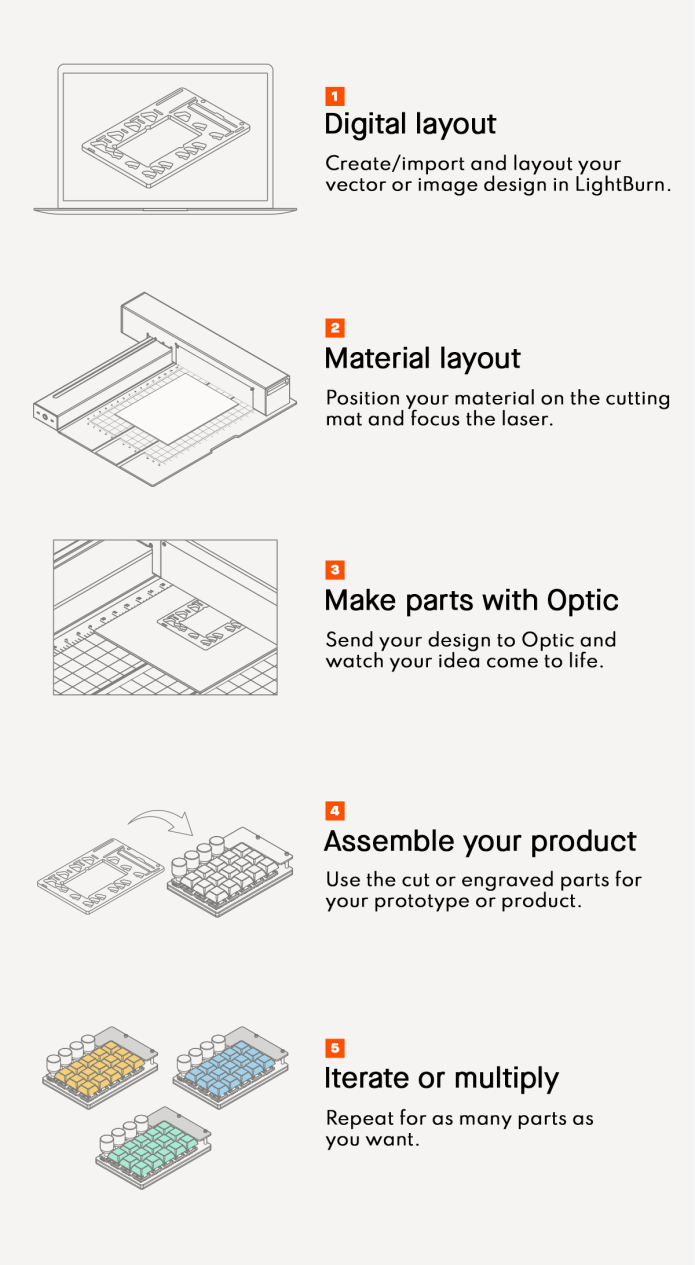

How Optic Works

The Optic combines CNC (computer numerical control) positioning with a high-power laser in order to precisely cut out your designs or engrave your artwork to help you go from idea to prototype to product with endless possibilities.

HERE’S ALL YOU NEED TO LET OPTIC WORK ITS MAGIC

YOUR FINISHED PROJECT!

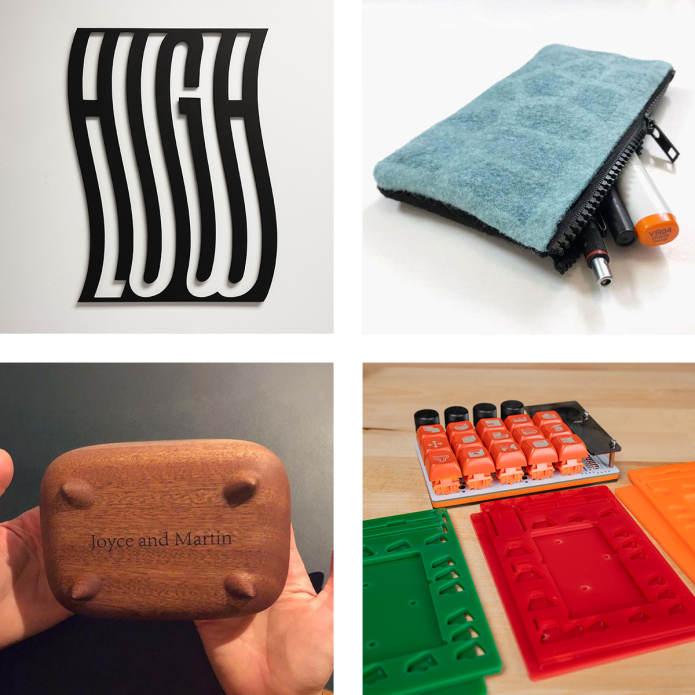

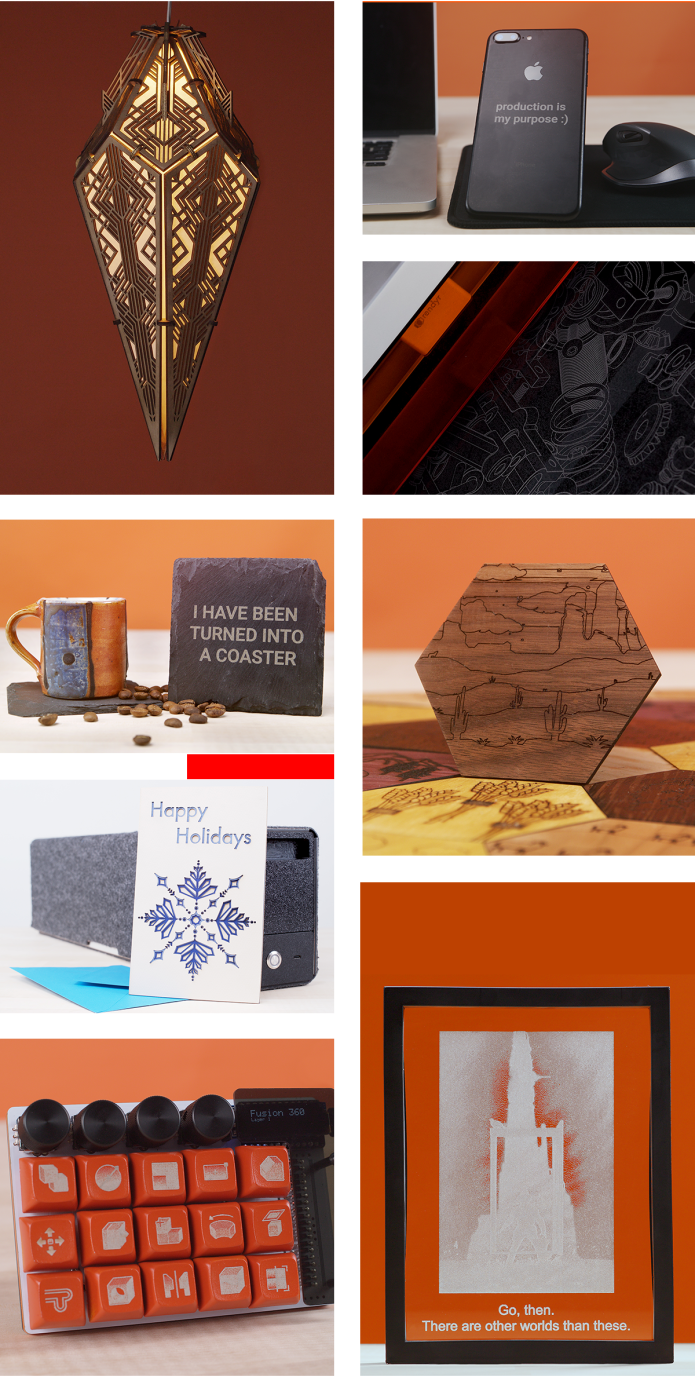

Here’s What You Can Make with Optic

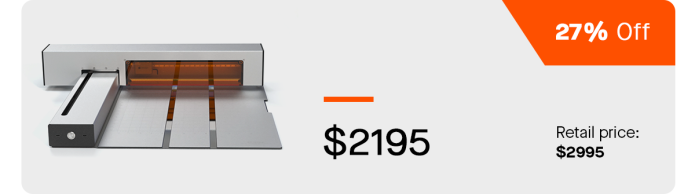

Rewards

Next, let’s take a deep dive into the features that make Optic unique.

All-Metal Kinematic System

HINGE PLATE MECHANISM //

IDLER WHEEL //

INDUSTRIAL PRECISION & ACCURACY //

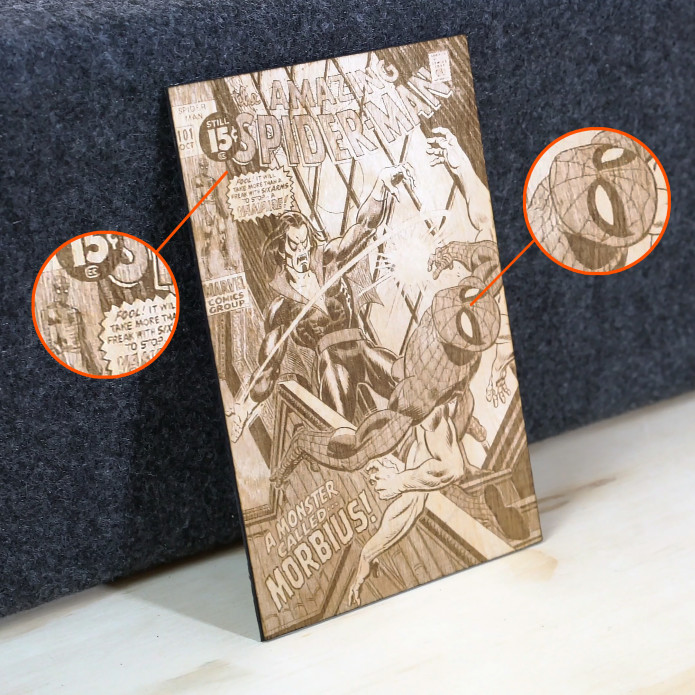

HIGH RESOLUTION ENGRAVING //

OPTIONAL ROTARY MODULE ADD-ON //

Optic’s optional Rotary Module enables engraving and cutting on cylindrical objects like bottles, dowels, and more! It works in combination with Optic’s Work Envelope Expansion Kit to hold objects up to 3” in diameter. The Rotary Module will become available as an add-on after the campaign.

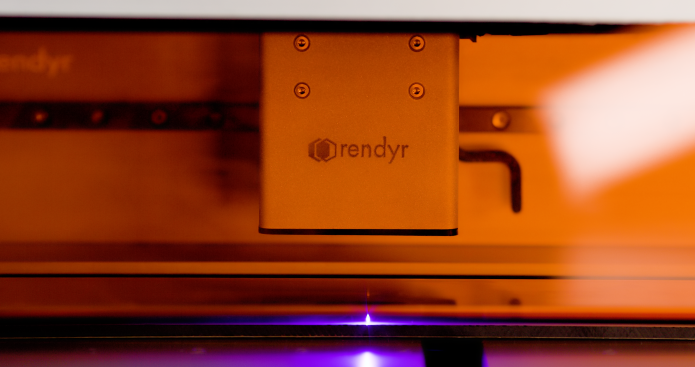

Optic’s Laser Module

Let’s deep dive into these features.

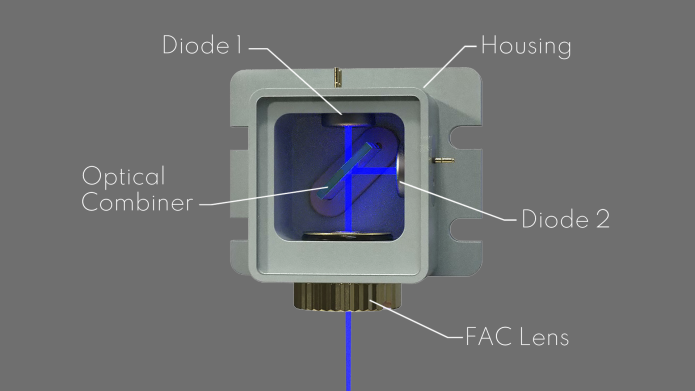

DUAL-DIODE LASER MODULE //

The Optic Portable Laser Cutter features our custom 15W multi-diode laser module to achieve the most powerful solid-state laser cutting available.

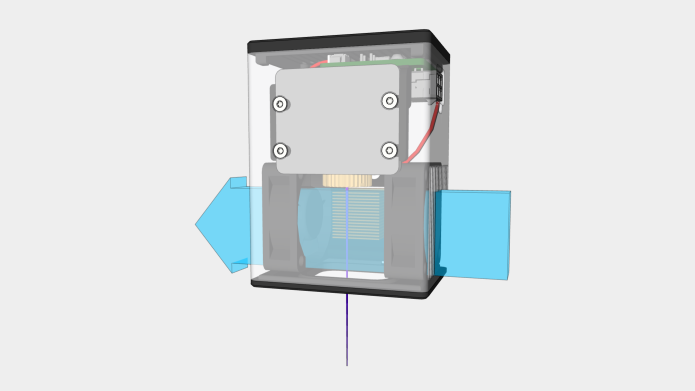

AIR-ASSIST CURTAIN //

Optic’s Air-Assist Curtain works in harmony with the integrated filtration system and minimizes the fumes in the beam path for optimal efficiency.

ACTIVE COOLING //

The laser module’s heatsink chassis and fans also actively cool the laser diodes to achieve the longest continuous runtime and lifespan under normal operating conditions.

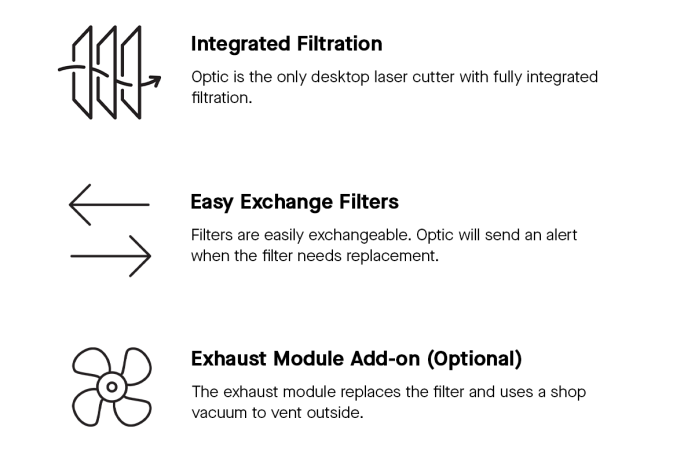

Optic’s Filtration System

Read on for a closer look at how the integrated filtration works.

INTEGRATED FILTRATION //

Optic’s integrated filtration system pulls in the fumes right at their origin, similar to dust shoes on CNC machines. The filters include HEPA-grade and high-activation carbon media to mechanically and chemically filter the fumes created from the laser cutting process.

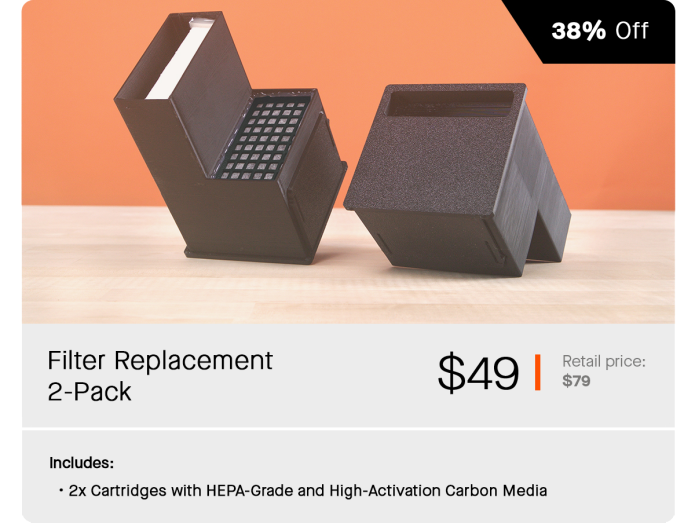

EASY EXCHANGE FILTERS //

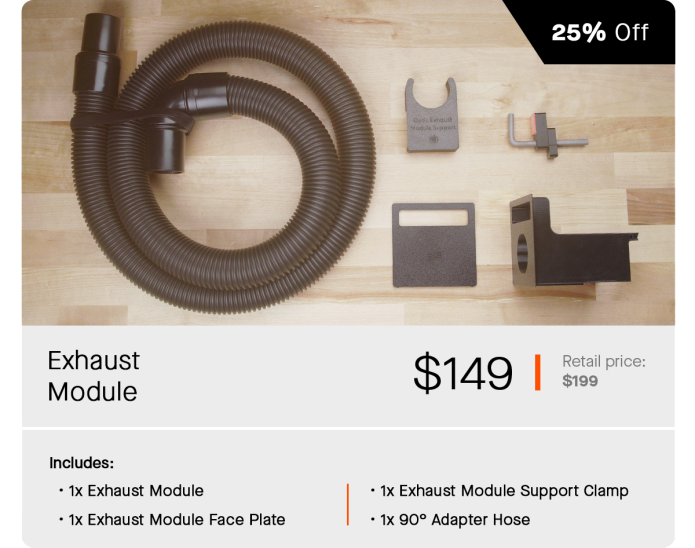

OPTIONAL EXHAUST MODULE ADD-ON //

This hot-swappable optional Exhaust Module easily installs in under a minute in place of the filter cartridge. We designed this add-on for creators who want to vent outside or connect Optic to an existing filtration system.

Optic’s Cutting Mat

Let’s dive into Optic’s flexibility features.

MULTI-LAYERED PROTECTION //

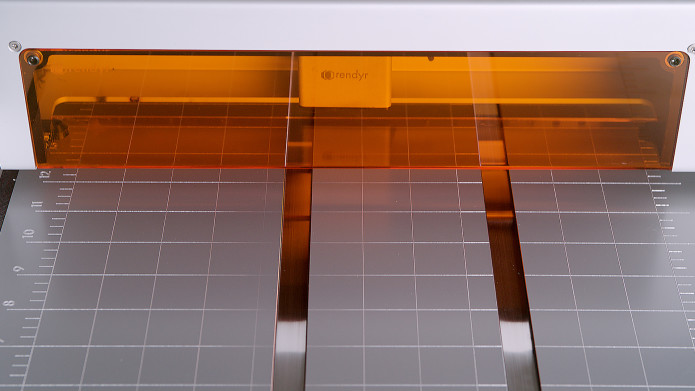

ALIGNMENT GRID //

Aligning your projects is now easier than ever! Optic’s calibrated cutting mat grid perfectly matches LightBurn’s grid so that you can precisely and intuitively align your digital artwork with the physical workspace.

See how we aligned and engraved these four cork tiles for this personalized pin wall. And in case you ask, yes, you can also use the alignment grid for batch production.

REMOVABLE DESIGN //

Simply detach the 18″ x 12″ cutting mat to use Optic directly on any surface, such as a large sheet of material or a butcher block table. Rubber feet protect the work object and ensure Optic stays in place.

Watch how the infinite work area feature lets you create projects of unlimited size:

POWERED BY INTELLIGENT MACHINE INDEXING SOFTWARE //

The infinite work area process is simple and does not require the exact positioning of the Optic. After repositioning the Optic, matching the laser pointer with two specified points on the artwork allows the included software, LightBurn, to precisely align the next tile in the sequence.

Power and Connectivity

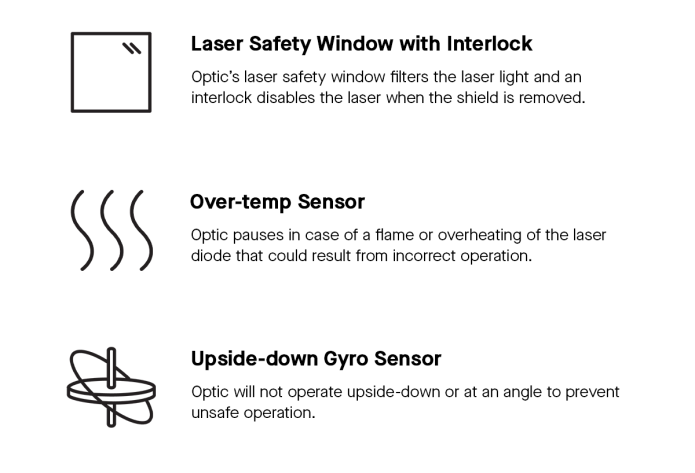

We Take Your Safety Seriously

Read on to get up close and personal with Optic’s safety features.

LASER SAFETY WINDOW WITH INTERLOCK //

OVER-TEMP SENSOR IN THE LASER MODULE //

Software Features

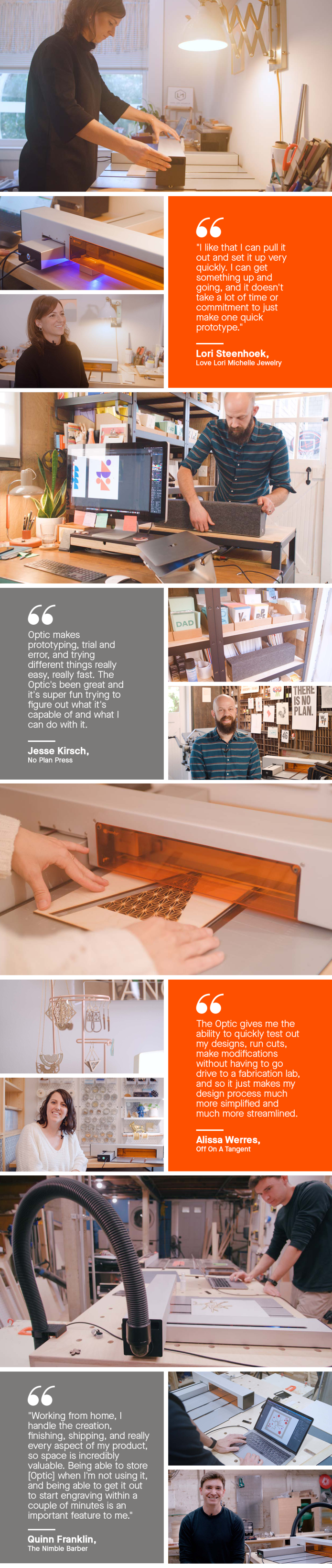

What Our Beta Testers Had to Say

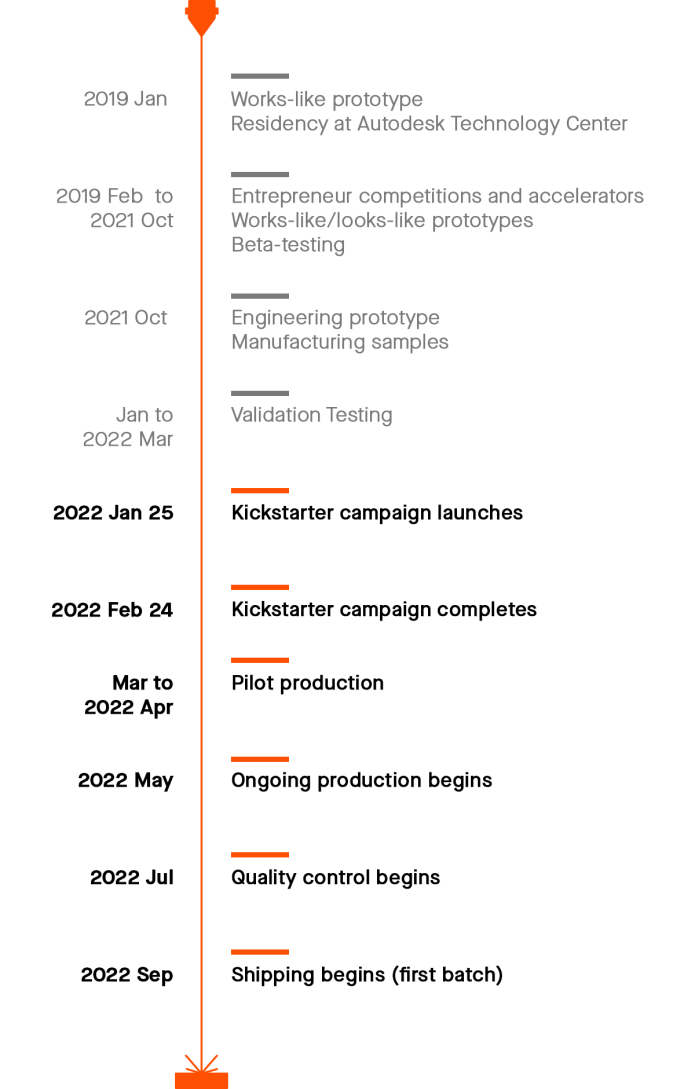

Timeline

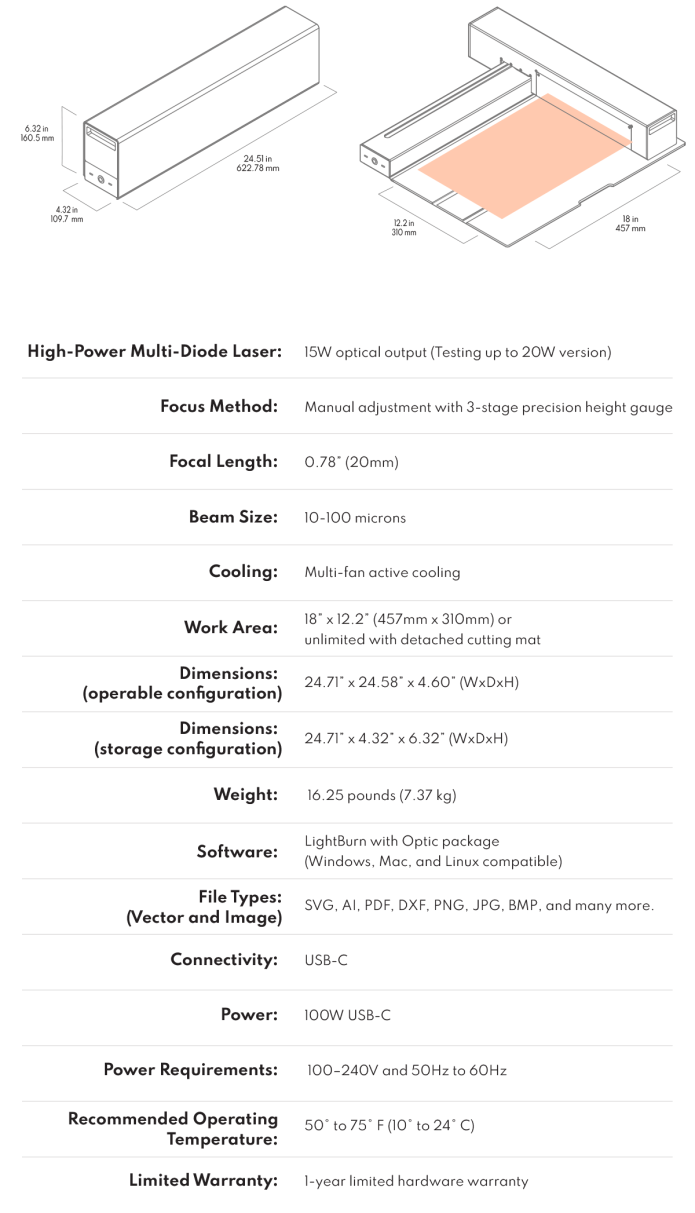

Tech Specs

*Specifications are based on the engineering prototype and subject to change at any time.

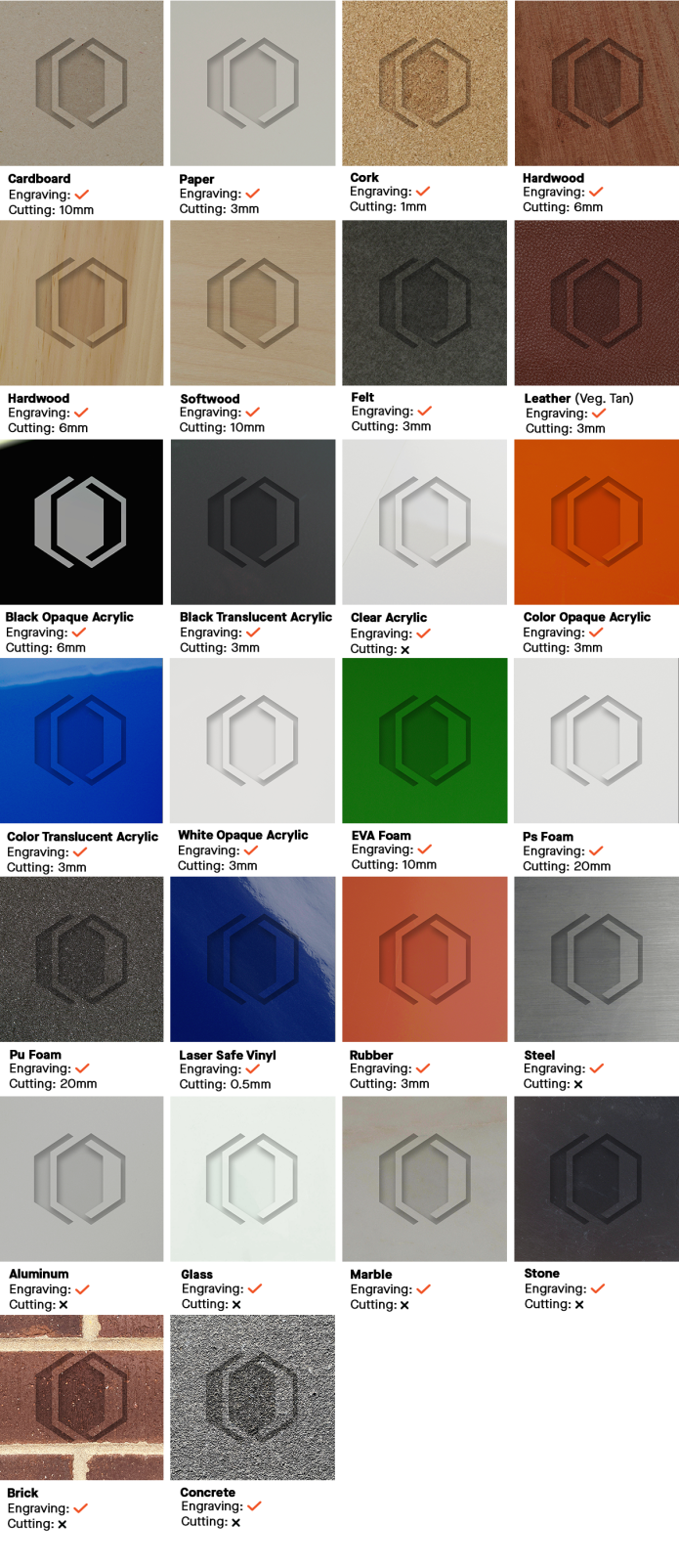

Supported Materials

In the Box

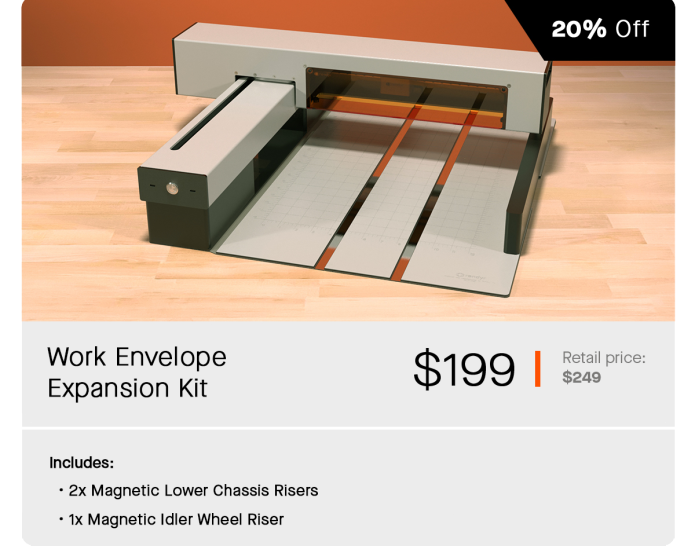

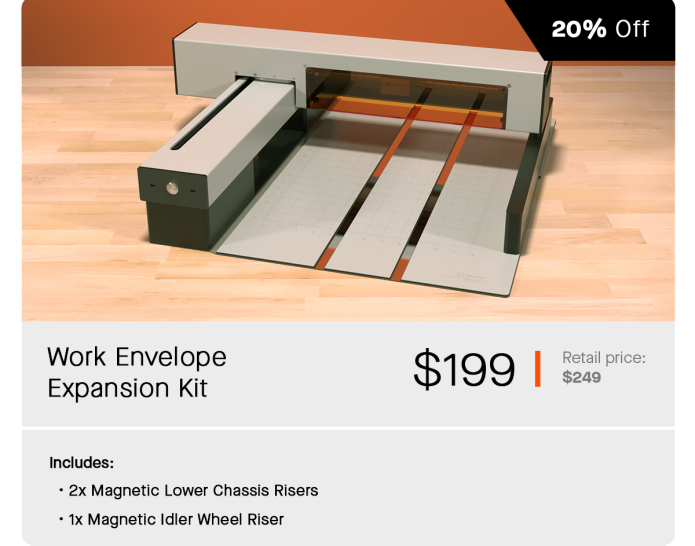

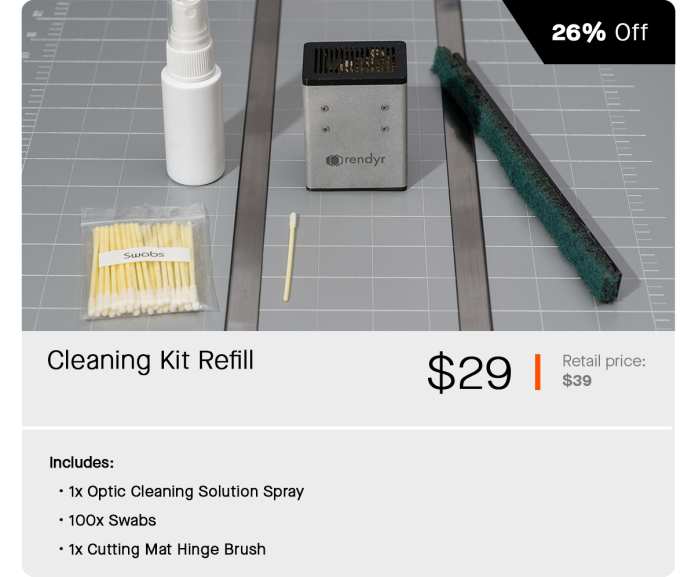

Accessories/Add-ons

Meet the Team

Optic is the result of our obsession with designing and making.

At Rendyr, the company behind the Optic Portable Laser Cutter, we believe that everyone should have the opportunity to create their own ideas with the most advanced technology available.

Co-founders Kaelum Hasler and Martin Angst have been passionate about laser cutters since they created their first industrial design prototypes and architectural models as students but were frustrated that the limited access to the machines presented bottlenecks to their projects.

When Kaelum pitched his prototype of a portable laser cutter to Martin after they connected over various robotic fabrication projects at Virginia Tech, Martin was sold and joined the team.

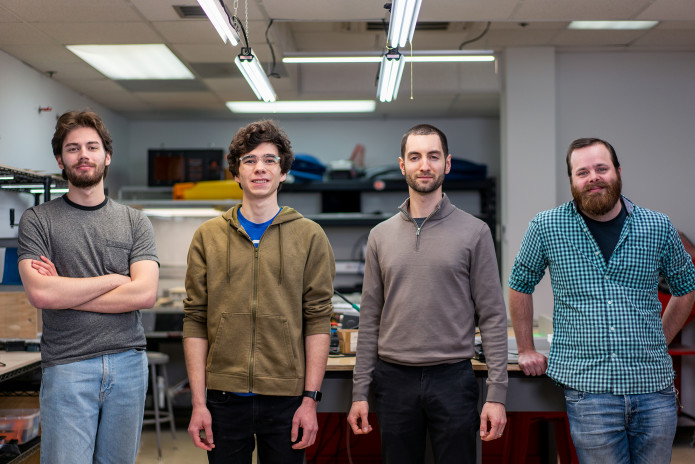

Team (left to right): Hans Stahl, Kaelum Hasler, Martin Angst, and Robert Worley

Fast forward, they bootstrapped research and development financed by awards from entrepreneurship competitions and programs and built a team of designers and engineers to bring Optic to you.

THE TEAM AT RENDYR

- Kaelum Hasler, Co-Founder

- Martin Angst, Co-Founder

- Hans Stahl, Engineering

- Robert Worley, Video & Content

With many thanks to our extended team: Lucia Fang, Travis Wiehe, Ryan Vargo, Alex Ryan, Charlie Brunner, Paris Parsons, and Jack Davis.

ADVISORS AND CONSULTANTS

- Doug Juanarena

- Ron Flanary

- Mike Abbott, Cambrian Design and Development

- Impact Solutions

- Christopher Estkowski, Applied Design Technologies

- Including our supporters from the Regional Accelerator and Mentorship Program, Lighthouse Labs accelerator, Apex Center for Entrepreneurs, and Autodesk Technology Centers, among others.

SPECIAL THANKS TO OUR CAMPAIGN COLLABORATORS

MUSIC CREDITS

- Breakmaster Cylinder

Social Media

Risks and challenges

We have built and tested more than a dozen prototype generations of the Optic Portable Laser Cutter over the last three years. Throughout design and engineering development, our team has been focused on product performance, stability, safety, and ease of use.

Our pre-production model delivers:

-Powerful laser cutting and engraving performance

– Cooling of the laser source and electronics with generous margins

– Reliable electrical connections designed for a lifetime of folding

– Robust kinematics for precision and accuracy

– Filtration for all specified materials

– Safe operation guaranteed by a laser safety window with interlocks and an over-temp sensor that can automatically halt machine operation.

– Intuitive machine and software interfaces

All custom part manufacturers have been qualified through initial production sample tests and inspections. All commercial-off-the-shelf components have been sourced, sampled, and tested through multiple vendors to ensure reliability and supply stability.

Once funding has been secured, the following challenges will be addressed:

SUPPLY CHAIN AND LOGISTICS

(specifically during the COVID-19 pandemic)

Rendyr is working with state-of-the-art manufacturing partners that have also supplied the industry-leading engineering and manufacturing companies led by our network of advisors. Our processes are being developed to be ISO 9001 compliant in order to ensure a smooth transition from prototype to production. While we will manufacture very few parts ourselves, we will perform final assembly, quality control, and shipping in-house so we can address any unforeseen roadblocks as quickly as possible. In anticipation of worsening global ocean freight shipping conditions, we have already arranged to leverage air freight to reduce inventory bottlenecks.

PRODUCT REGULATIONS

Rendyr is in the process of obtaining UL/CSA 62368-1 and IEC 60825-1 product certifications with TUV Rheinland of North America. TUV is the independent accredited testing and certification company that has evaluated other laser cutter products such as Glowforge Pro, a Class 4 laser product designed for public consumption. We anticipate product certification testing to begin no later than February 12, 2022. The test plan is designed with Optic as a Class 4 laser product to ensure compliance at the highest level. The classification may be modified if the independent evaluation proves a reduction in classification is warranted. We estimate this evaluation and certification process will be completed by July 2022, allowing all applicable product marks, labels, and product documentation to be included before the first shipment.