The AUTOMATED Table Saw Fence

Short Summary

Rip-it‚ĄĘ is a retrofit system that adds affordable automation to your existing table saw setup. Professional woodworkers love Rip-it because it is fast, precise, and easy to use. Table saw work goes¬†up to six times faster!¬†Rip-it¬†pays for itself within weeks in a busy shop.

The system includes a motorized fence with touchscreen control, rack rail, and angle bracket. Here is a brief video showing the core function of Rip-it: dial your desired cut width, the fence moves quickly into place, and then make your cut

Rip-it was invented by master cabinetmaker Jeff Hadaway, who recruited a team of skilled designers, engineers, and businesspeople (‚ÄúTeam Rip-it‚ÄĚ) to develop a robust product and bring it to market. Team Rip-it¬†launched the product first on¬†Kickstarter in July 2023, aiming to¬†raise¬†$150k¬†for¬†final development and manufacturing setup costs. And we succeeded! The campaign ultimately raised $216k from 211 backers. Their support has validated that customers are excited about the product and provided the necessary funding for the first¬†production batches.

Since the Kickstarter, we have heard from several others who want to back the project. In response, we have opened this Indigogo InDemand campaign! InDemand is a platform that enables companies to continue raising money as they start manufacturing and delivering products after a successful crowdfunding campaign.

We are now offering Rip-it as an InDemand backer reward. With this limited-time offer, woodworkers can get Rip-it at a discount off the MSRP while helping to support the manufacturing launch as it occurs. Our target date to fulfill InDemand backer rewards is MAY 2024.

Between now and then, we are finalizing the details of the product design, purchasing components inventory, setting up production, and then making and delivering the first batches of Rip-it. As that work proceeds, we will post updates here on InDemand (and via email and social media channels) so backers and supporters can follow the progress.

What We Need & What You Get

The previous Kickstarter crowdfunding campaign provided¬†sufficient¬†capital for us to start production and deliver Rip-it to campaign backers. Team Rip-it is 1000% committed to delivering a finished, robust product¬†and we¬†are immensely and eternally grateful for backers’¬†support.

While additional funds are not needed to launch the product, they would certainly be helpful as we navigate the details and uncertainties of the production launch and build up inventory for future deliveries and sales. Additional funds would allow us to order larger quantities of machined parts and components, reducing costs and supply chain risks.

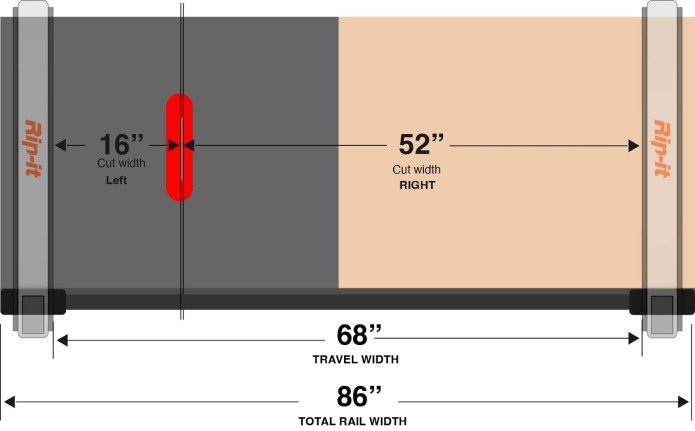

For Indigogo InDemand backers, we can offer¬†a¬†complete¬†Rip-it fence system as a backer reward. The complete system includes¬†the digitally controlled fence, rail, and bracket to retrofit your existing table saw and table. The standard rail is 86″, which provides 52″ of rip capacity on the right side of the blade and 16″ on the left in our recommended configuration (see below), and users can move or cut the rail shorter to fit their table setup. Our¬†target¬†date for fulfillment of InDemand rewards is¬†MAY¬†2024.

Key Features

Rip-it is the product of careful, iterative design and development. The result is a product that is functional while also being robust, full-featured, and easy to use.

Intuitive Touchscreen Control

Control Rip-it via the touchscreen with an intuitive, high-contrast interface that offers the choice of SAE or metric units and fractional or decimal display. The current design includes a 5.5″ screen, and the final production design will have a 7″ screen.

Auto Locking

Once it reaches the precise location, Rip-it automatically locks firmly into place with no action required by the user.

Automatic and Manual Calibration Options

Activate the auto calibration with a push of the button. Rip-it moves gently to touch the blade and detect the zero point. Or, calibrate the zero manually and set it at your preferred location. Rip-it only needs to be calibrated once at startup and will maintain accuracy for the entire shift.

Choice of Units

Users may select inches in fractional or decimal formats, centimeter, or millimeter units.

Jog Function

Use the jog buttons to control the motor directly, moving the fence in either direction for small or large adjustments.

The Impact

This project is the culmination of a¬†dream that is years in the making. Jeff (the inventor) had the idea for Rip-it over 20 years ago. He had a prototype created and¬†called the product “Pick-it Fence.”

That initial attempt to bring the idea to market did not succeed, and the dream went on “pause” for a while, but Jeff never let it¬†go. It stayed in the back of his mind. Eventually, he decided to try again. He recruited help from Steele Inc., a product design firm, to upgrade and update the product¬†with modern materials and technology.

The first update Steele Inc. designed featured a touchscreen, modern software control, and an aluminum unibody frame.

Another (very shiny) prototype was created for live testing in professional shops.

The 2023 update included a host of design-for-manufacturing improvements. The final version shipped to backers will be similar to this version but with a few additional enhancements, including a larger touchscreen, more robust mechanicals, and accessory T-slots on the top.

The product is being brought to market by the Rip It Fence Company, which is based in Corvallis, Oregon, and has a manufacturing facility in Roseburg, Oregon.¬†Our company mission is to¬†fulfill¬†Jeff’s dream, deliver the product to all the backers, and then continue manufacturing and selling it in the future. We also have plans to develop¬†a series of other¬†affordable automated¬†tools¬†for professional woodworking shops based on the same technology platform developed for¬†Rip-it.

Risks & Challenges

Developing any new product entails inherent risks, challenges, and uncertainties. We are highly aware of those and have worked to identify and mitigate those as best we can.

One issue companies of all sizes and types have had to deal with lately is supply chain disruption.¬†Manufacturing companies are¬†particularly¬†vulnerable if a key component becomes unavailable. With this in mind, we use common “off-the-shelf” parts as much as possible and have identified multiple suppliers for most of them. We also have identified local domestic¬†suppliers for extrusion, machining, and anodization of the custom aluminum parts that go into Rip-it.¬†

Many new product companies struggle during the development stages due to delays, cost overruns, or failure to meet customer requirements and demands. To mitigate those risks, we have pursued an agile development strategy that involves building multiple successive prototype versions and incorporating user feedback and testing into each step. This way, we ensure we are developing what customers need and want.

Some companies fail because of cash flow problems or because their business model has fundamental problems. To mitigate these risks, we carefully identified each component on the bill of materials and created detailed COGS and operating expense forecasts. We have received updated parts quotes and secured the lease on our manufacturing facility since the Kickstarter campaign ended, and our forecast model has proven to be accurate so far

Ultimately, our goal is not just to get crowdfunding money. Our goal is to create a business that lasts. With that in mind, we have done and continue to do everything we can to make sure the Rip-it launch is successful, backers receive a great product as promised, and the business is sustainable in the long run.

Other Ways You Can Help

We have gotten this far thanks to the interest and support of many people, including woodworkers, media partners, service providers, and others who have helped us in various ways over the past few years.

We are offering Rip-it on InDemand to offer one more chance for people to pre-order at a discount before the official launch.

And even if you don’t become a backer, you can help us spread the word!¬†Tell your woodworking friends about the product, hit “like” to boost our page prominence, and use the Share Tools links to mention us on Facebook,¬†copy the link to share anywhere, and like and follow us on Instagram and YouTube.