4’11″x8’2″|Fully Enclosed & Smoke-Free|LightBurn CNC| 60W Adjustable Laser | 90% Pre-assembled

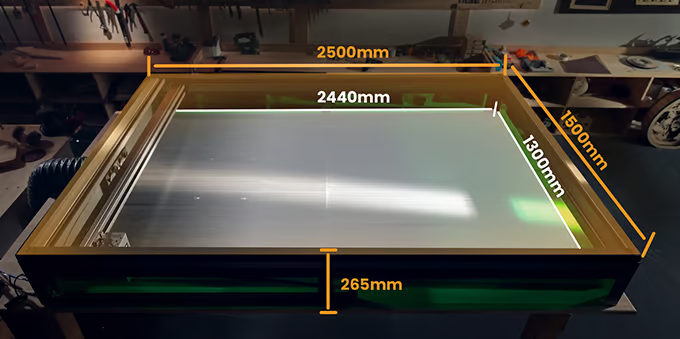

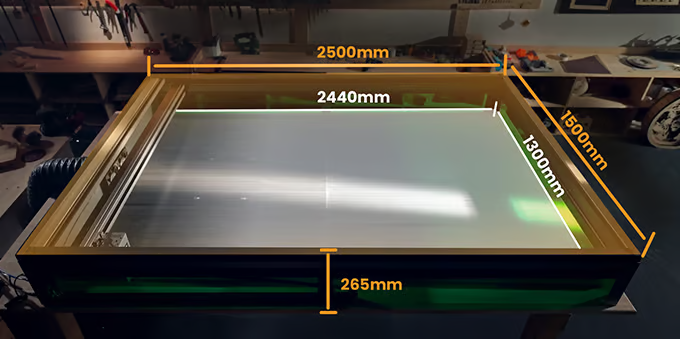

Receiving a lot of feedback from our European users, we decided to further upgrade the size of all 4’1″x8′ Spider S1 machines to 4’11” x 8’2″ (1500x2500mm), with a working area of 1300x2440mm! This means both U.S. Standard Full-sheet (1220mm x 2440mm), as well as European Standard Full-sheet (1250mm x 2500mm), can work directly with Spider S1, reducing material waste and making the process more efficient!

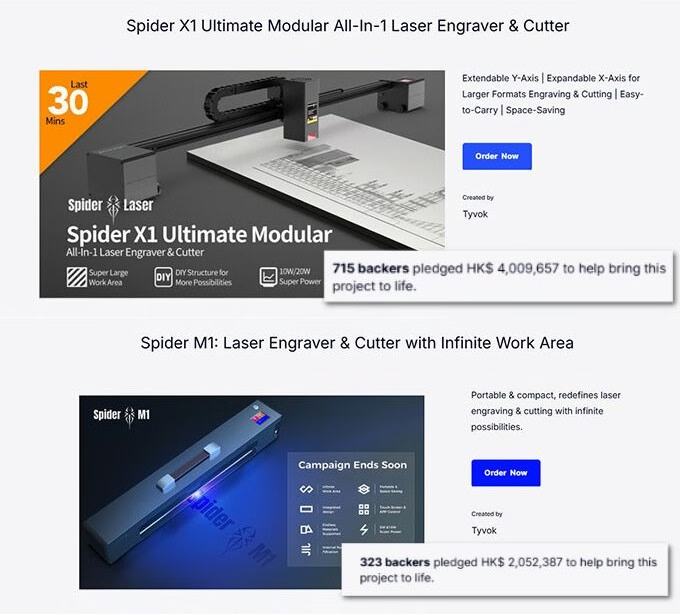

It’s Tyvok Again!

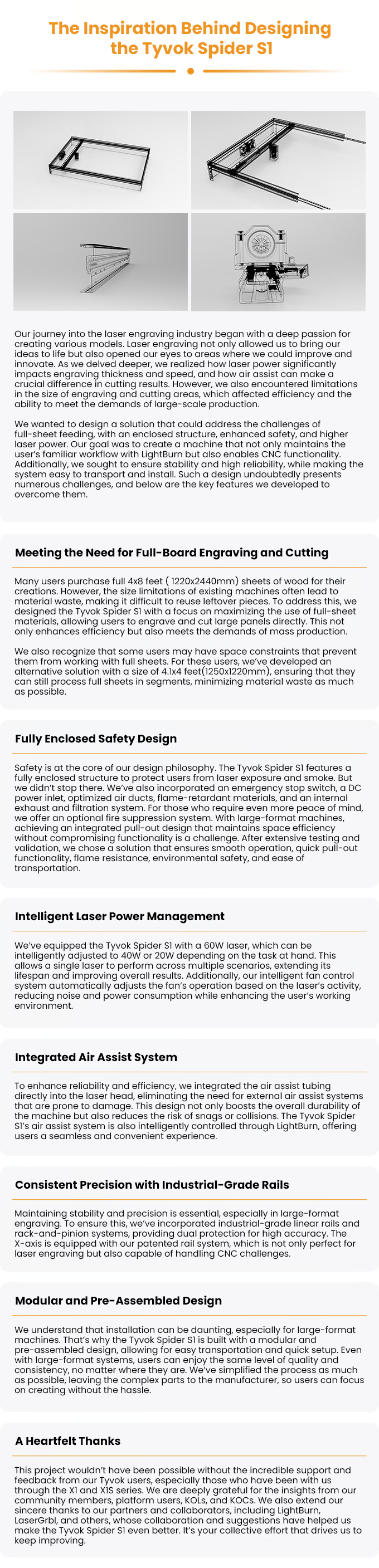

Over the past two years, Tyvok has successfully launched and fulfilled two highly innovative projects. Building on the experience from those projects and continuous product innovation, along with user feedback, Tyvok has been pushing the boundaries of laser engravers, exploring new possibilities. This time, we’ve truly expanded those boundaries!

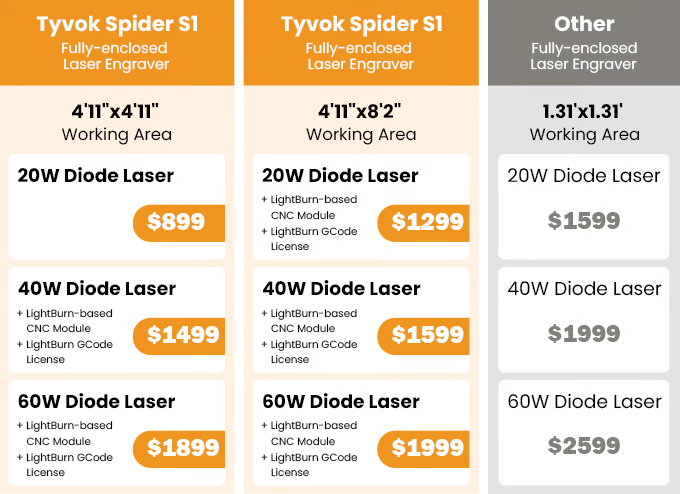

Tyvok Spider S1 Vs. Others

Spider S1 ‘s expansive 4’11” x 8’2″ (1500x2500mm) work area is able to handle the whole board at once. Perfect for large-scale projects as well as mass production. Save yourself the hassle of multiple cutting sessions and material changes.

No need for pre-cutting or preparation. From now on, you can start working directly with whole boards! The Spider S1’s unique front-opening design allows you to easily slide entire boards in from the front. This not only saves you time but also maximizes material usage and minimizes waste.

The Spider S1 features a fully enclosed design that prevents smoke and laser leakage, ensuring user safety even after extended working hours.

With its top cover made of high-performance flame-retardant materials, S1 provides an extra layer of safety for users.

S1 is also equipped with a safety lock. If the top cover is opened suddenly during operation, the machine will automatically stop to minimize laser and smoke exposure. However, if you need to monitor the progress at any time, you can disable the safety lock in the machine settings.

Unlike traditional machines that struggle with smoke and noise, the Spider S1’s automatic fire control and efficient exhaust system keep your workspace clean and secure.

Specific projects can generate significant smoke and dust, impacting your experience and work quality. The Spider S1 addresses this with an integrated smoke fire extinguishing system that automatically manages fires or high temperatures, ensuring safe operation. With the built-in mini fire extinguisher, user and product safety is ensured even in the event of an unexpected flame.

With the advanced thermal aerosol technology, each unit effectively protects a 0.5 cubic meter area, and with two units, a 1 cubic meter space is fully safeguarded, providing comprehensive coverage for the entire enclosed area.

Since the primary fire risk is located near the X-axis laser head, deploying mini fire suppression units at both ends of the X-axis is generally recommended.

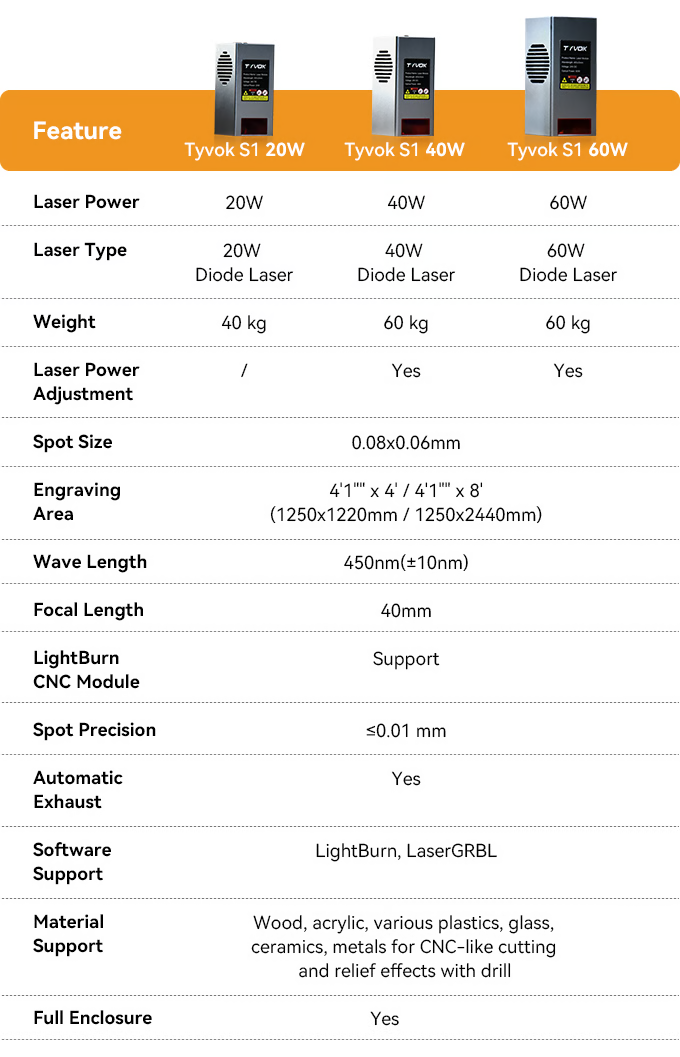

The 60W semiconductor laser equipped on the Spider S1 is powerful enough for your most ambitious ideas.

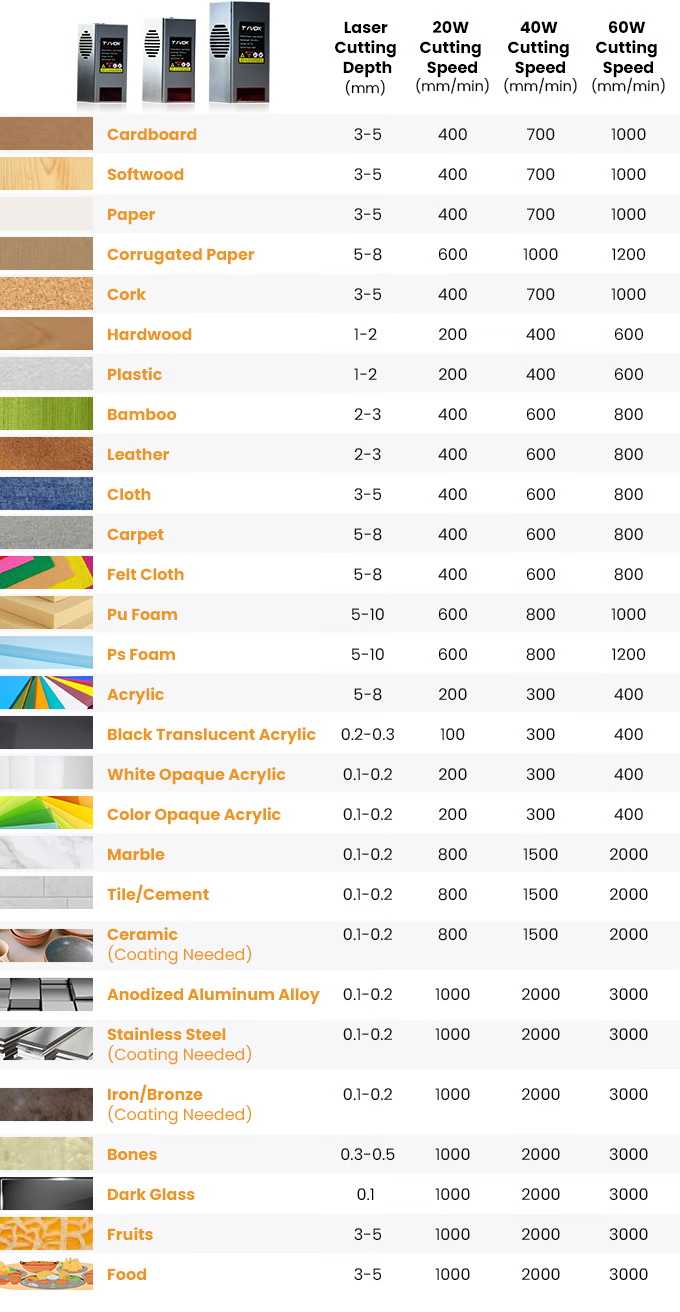

The laser head is equipped with an automatic frequency reduction feature, allowing the power to be adjusted from 60W down to 40W and 20W. This reduction in power not only minimizes the spot size for more precise engraving on different materials but also extends the laser’s lifespan.

With its high-power 60W laser, the Spider S1 dramatically improves work efficiency. The increased power enables quicker engraving and cutting, allowing you to complete projects faster.

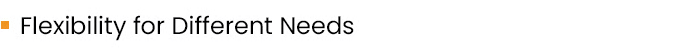

Spider S1 has undergone extensive testing on various materials, thicknesses, and power settings. Here, we can showcase some of these tests across different materials to help users easily set the optimal parameters during use. This provides users with a reference for achieving the best performance and precision.

The laser fan automatically starts and stops, making work safer, quieter, and smarter.

Built-in Air Assist Duct: The system features a built-in air assist duct, eliminating the need for an external air assist setup. This integrated design results in greater precision and a more streamlined appearance.

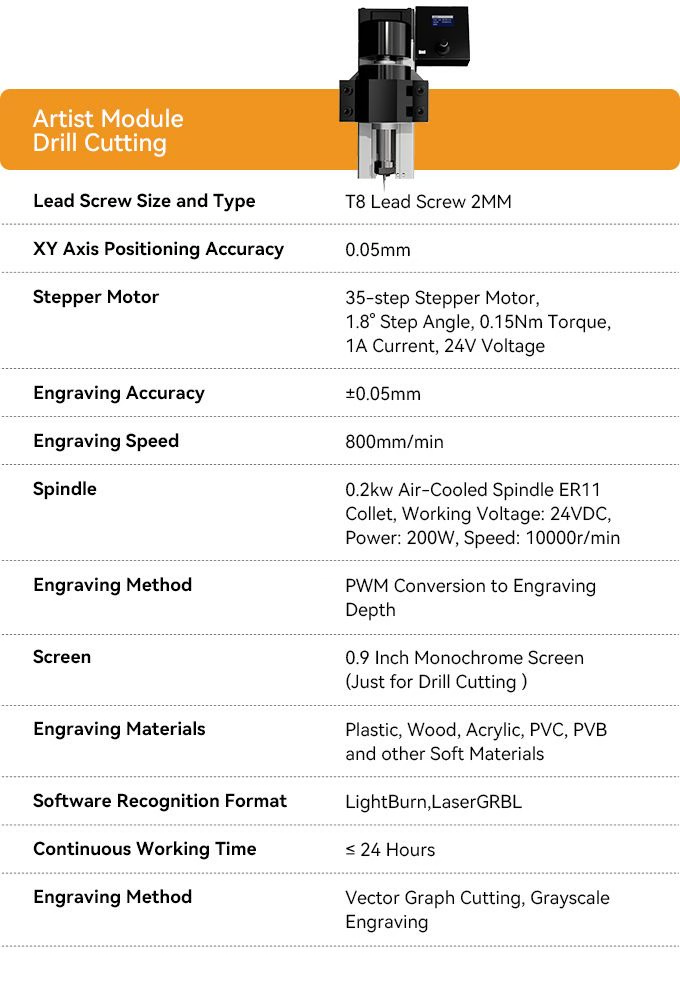

Not only laser, the Spider S1 also excels in high-precision CNC cutting based on LightBurn.

Equipped with its 2nd-gen Artist Precision Module, you can easily create stunning reliefs and dive into woodworking with a minimal learning curve.

The CNC module based on LightBurn is a module that reads the laser PWM protocol and maps the grayscale values to the set depth values. It allows laser engraver users to compile toolpaths in LightBurn through simple settings, enabling basic CNC cutting tasks.

With the Spider S1, all you need is easy-to-use laser engraving software to perform both relief engraving and cutting. No specialized CNC knowledge is required, the module can be easily operated through LightBurn and LaserGRBL.

Thanks to its self-developed rack and gear coupling system, Spider S1 effectively reduces errors even when the work area is expanded, ensuring perfect results for large-format engraving and complex cuts. The Spider S1 consistently retains its accuracy, allowing seamless upgrades and expansions without sacrificing performance.

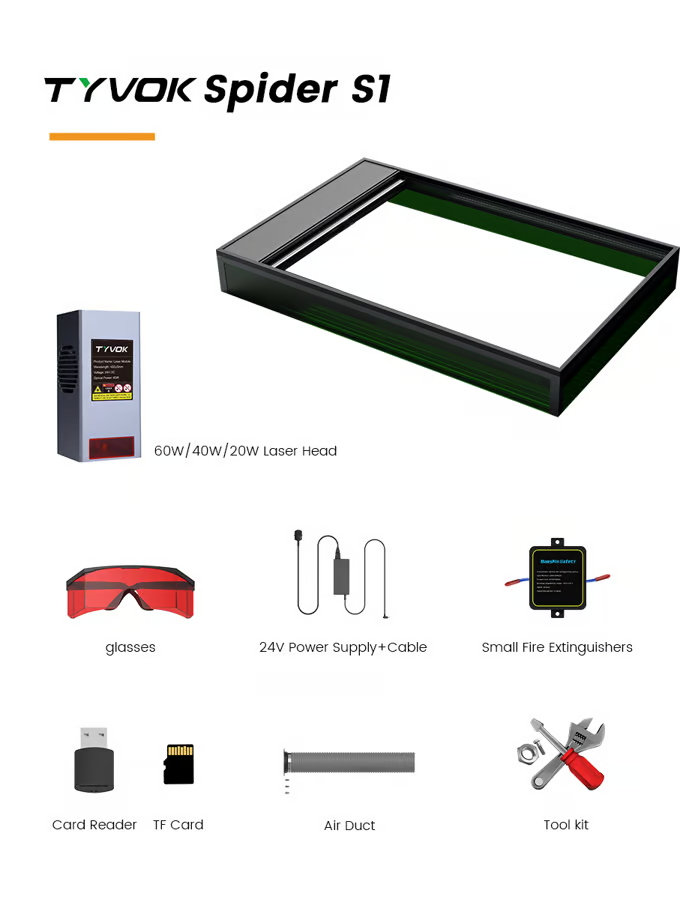

While the Spider S1 offers top-tier professional features, its installation process is designed to be beginner-friendly. The machine is divided into four main modules, each pre-assembled with key components. Users only need to connect the frame using plug-in connectors, ensuring a quick and stable assembly process.

The newly developed support kit now allows users who select the 4’11″x8’2″ version to choose between installing a 4’11″x4’11” half-size board or the full 4’11″x8’2″ size, based on their specific needs. It’s like having two large-format machines in one, and can easily switch between them as needed.

This accessory kit, valued at $99, is completely free for Kickstarter backers, as a special thank-you from Tyvok. We invite you to take advantage of this offer and enhance your creative projects with greater flexibility and freedom!

For business owners with mass production needs, the Spider S1 supports controlling multiple machines from a single computer. This allows you to execute the same or different tasks across several Spider S1 units simultaneously.

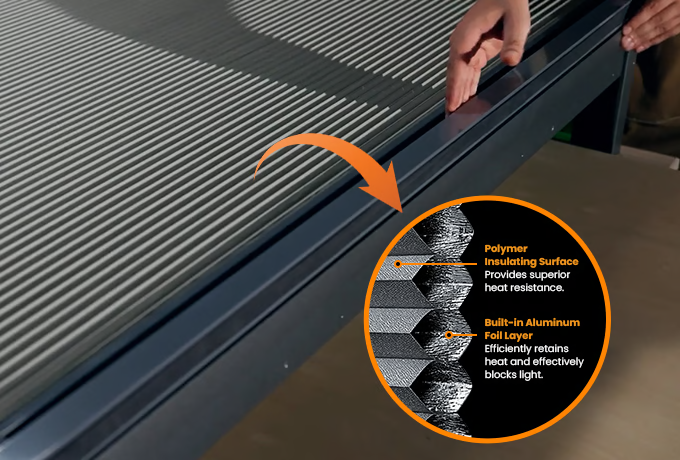

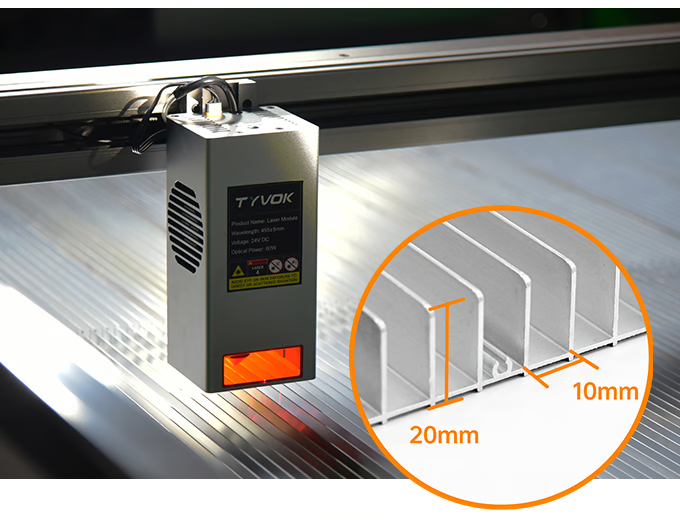

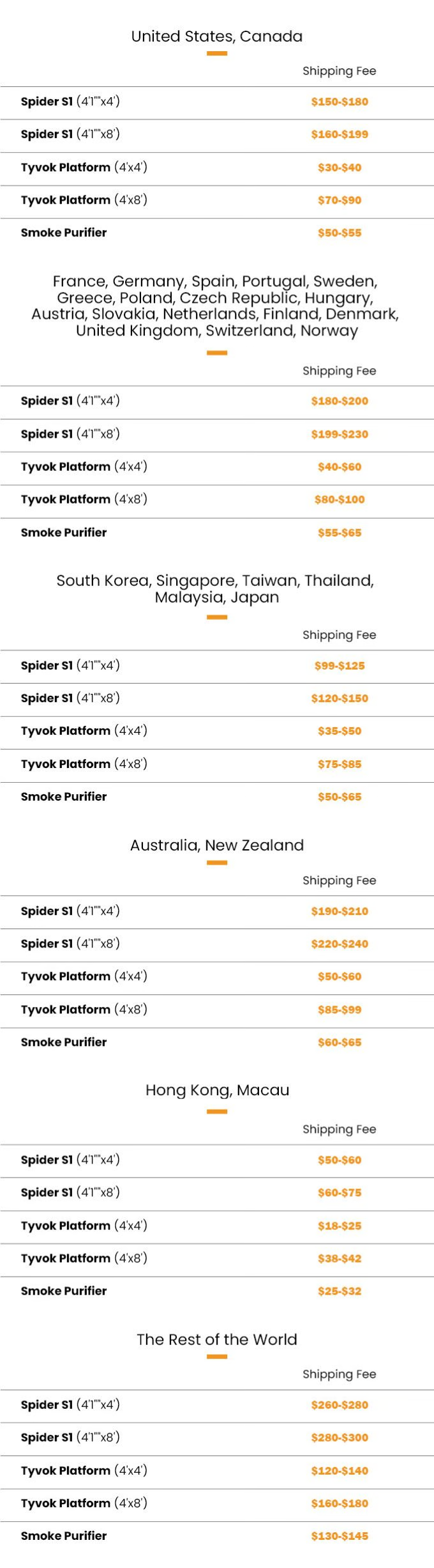

The lightweight, integrated platform board is 70% lighter than conventional honeycomb boards, making it ideal for large-format projects.

Its unique elevated design effectively aids in venting the smoke generated during laser cutting.

The Tyvok expandable platform board is lightweight, easy to expand, easy to clean, heats evenly, and does not require a steel plate.

*Please note that the platform board needs to be added separately as an add-on.

Tyvok will provide a 1-year warranty on machine parts and hardware, 3-month warranty on laser tubes and power supplies, and quality assurance service to all backers of this Kickstarter campaign.

Any quality issues caused by non-human factors under reasonable and proper use. The warranty does not cover products that have been improperly stored, assembled, or used. It also does not apply to damage caused by accidents such as tearing, cutting, or scratching. If any such issues arise, we will supply free replacement parts.

The warranty period starts from the date of delivery, and proof of purchase must be provided.

Got questions? Check out Tyvok Wiki

Share your creations with us at SpiderMake

Learn more: Explore the Tyvok Official Website

Shipping costs will be charged separately after the project ends. Due to the large size and weight of the Spider S1 and some of its accessories, even slight fluctuations in international shipping rates can result in significant price differences. To ensure you don’t pay more than the actual shipping cost, the shipping fee will be collected separately through a backer survey before shipping officially begins.

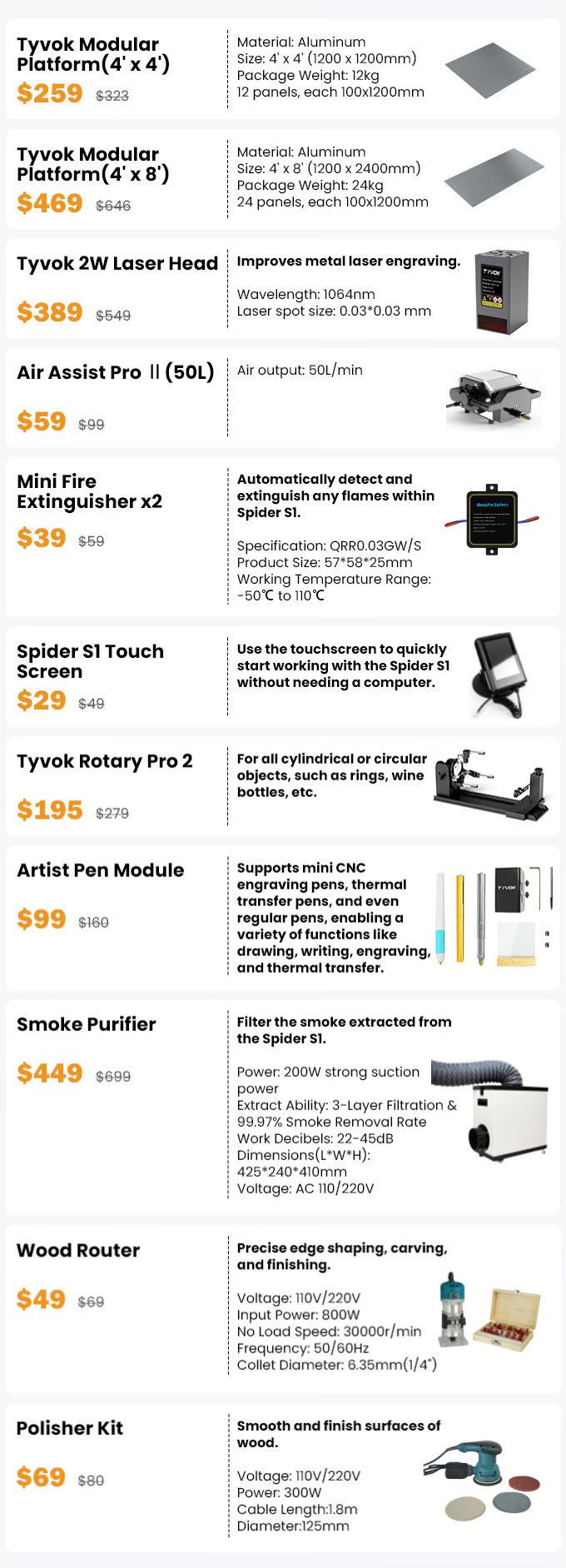

You can refer to the following table for an estimate of the possible shipping cost range. We will also do our best to secure the most favorable rates.

The Smileme team is committed to the continuous exploration in the field of laser engraving and cutting. Our team members come from world-renowned companies in various fields such as structure, algorithms, electronics, hardware, software, etc.

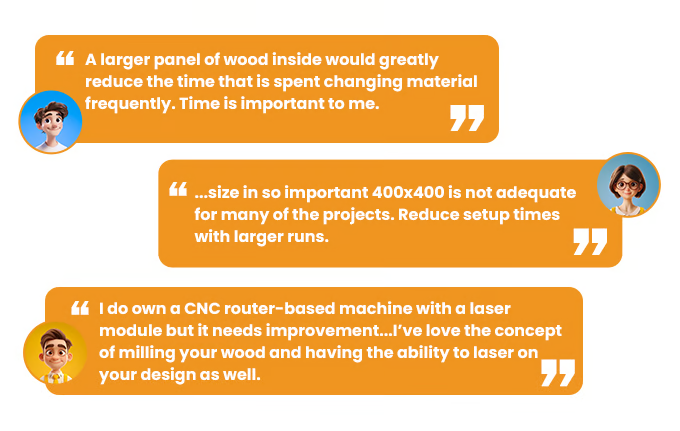

Our team has experts in professional modeling. In the ongoing production process of medium and large format modeling, we deeply suffered from using the engraver and cutter with the current X-Y structure, which has problems like low space expansion, high cost, heavyweight, not enough portable, etc.