Return of an American-made pure wool blanket

Story

“bringing a renewed sense of pride, not only in his family name, but to a new generation of U.S.-based manufacturing with the Chatham Blanket”

-The Manual

Alexander Chatham founded his woolen mill in 1877. By the time of his death in 1920, the Chatham Blanket was world famous. For over 100 years, the Chatham Manufacturing Company made its legendary blanket until the mill shut down.

This project is a revival. American-made from pure wool, using traditional manufacturing processes, we’re recreating the original Chatham Blanket.

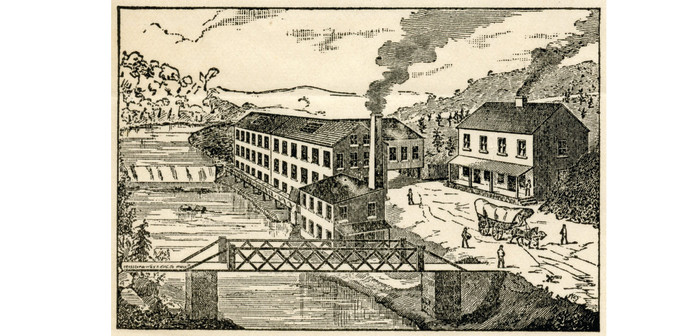

The Chatham Mill in 1893

The Chatham Blanket

This Indigogo will support the re-issue of a Chatham Blanket. The original blanket was manufactured in the late 1800s by the Chatham Manufacturing Mill in North Carolina. Shepherds would bring wool to the mill and receive blankets back to sell or use themselves. They were soft but durable. An incredibly versatile blanket that can stand up to years of indoor and outdoor use.

Weight

The blanket is 20.5oz wool cloth. This is the same weight as WW2 army blankets, which soldiers would sleep under outside in winter. It holds in heat extremely well, while still being breathable. It also wicks away moisture. The colors are reproductions of the original dyes, using modern processes.

Construction

It is 100% pure wool. Twill weave on a dobby loom. The finish is a perfect, soft nap, which gives it softness, and some of its insulating properties. The edges are bound with a whipstitch.

The Chatham Blanket fully spread out. Size is 60X76

Size

The blanket is 60x76in. which is throw sized. It’s designed to be versatile, and portable for use at outdoor events, or next to fires.

Durability

If cared for, this wool blanket can last for generations.

Blanket Specs

- 100% fine wool

- 20.5 oz.

- Throw 60x76in.

- Whipstitch bound

- Made in the US

- Dry clean or hand wash cold

The History

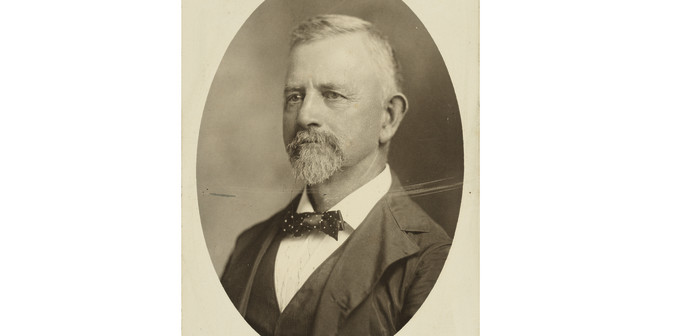

Alexander Chatham

1868: Alexander Chatham starts working as a clerk at a small water powered gristmill and installs wool carding machines in order to process local wool. The area around the mill is full of sheep and there are no woolen mills in the south.

1877: He installs weaving and finishing machines so that they can turn wool into finished goods at the mill. The first Chatham Blanket is made.

The first Chatham woolen mill

1890: Hugh Gwyn Chatham succeeds his father as president of the company.

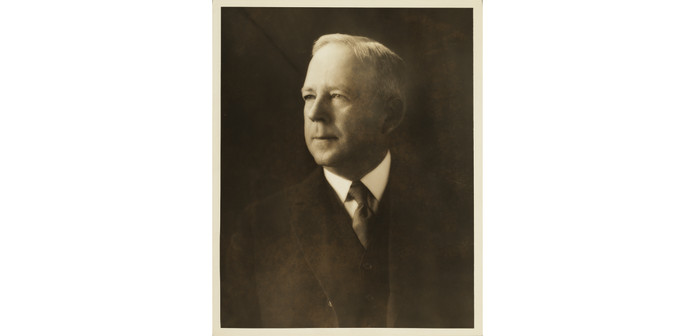

Hugh Gwyn Chatham

1893: The mill is moved to be near a railroad so that Chatham Blankets can be more widely distributed.

1917: The company manufactures wool blankets exclusively for the US and French militaries in WW1. Their wool blankets are tested in battle.

1927: Chatham Blankets are sold across the country in upscale department stores

1929: Thurmond Chatham succeeds his father as president of the company.

Thurmond Chatham

The Chatham Mill in the 1930s

A Chatham Blanket ad from 1937

1941: Chatham Blankets go to war on every front, covering every branch of the military while the company’s president, Thurmond Chatham, commands a cruiser in the Pacific.

A soldier sleeping under an 8-111 Spec Army blanket. Chatham made millions of them in WWII.

1951: In addition to blankets, Chatham manufactures wool interiors for car brands including Ford, Chrysler, Nash and Studebaker.

1988: Chatham leaves family hands when it is taken over by a Danish holding company and quickly dissolved. The mill is sold a few times during the next several years and dwindles until it is completely shut down.

Research

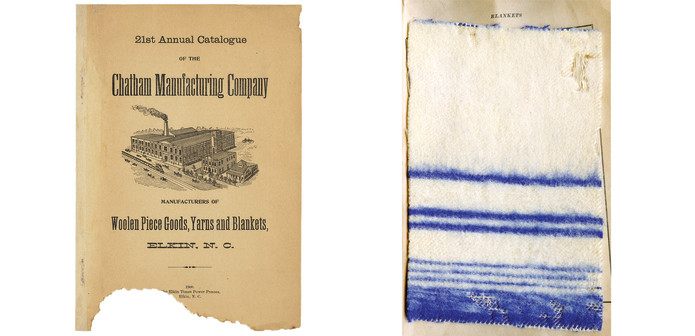

Chatham Blankets have been a part of family lore for my entire life. I have become more and more interested in them over the last several years. I started this project with the aim of reproducing an authentic Chatham Blanket, but I didn’t have any original source material to work with. I had a few vintage blankets, but I wanted to find the originals, the ones that started it all. I went through a rigorous research process to find what I was looking for. I searched libraries and museums across the US, scoured Ebay, and sent a few cold emails to try to find original Chatham blanket designs.

Original archival wool watches

In Elkin: Images of America I discovered Chatham Mill photos and decided to reach out to the author, Jason Couch. An Elkin historian whose grandparents worked at Chatham Manufacturing, Couch had a Chatham Manufacturing catalog from 1894. This was it! The catalog contained several 130 year-old pieces of wool blankets. From these original blanket swatches and some vintage photographs, I was able to reverse engineer the entire blanket designs.

A late 1800s photograph of a Chatham Blanket being made.

Making a Wool Blanket

Producing a vintage style wool blanket in the US today is a huge challenge. There are only four mills still operating that process wool and finish blankets in the same way. The Chatham mill, and countless others are long gone. The machinery and knowledge required is rarer and rarer. From the way the wool is dyed, through the way it is carded, spun and woven, nuances of the process determine the final product and only the few operating mills can still make ’em like they used to.

I learned everything about the wool blanket making process during this project, and that helped me to find the right mill to work with. I visited a few mills and studied details of the processes. I referenced Chatham archival material to correlate the current manufacturing methods of these mills with the historic processes of Chatham.

The mill that I am working with has been operating in Connecticut since before the Civil War.

Discussing wool fabric constructions

Carding

Wool being fed into the front end of a card

The first step in making wool blankets is called carding. The wool that arrives at the mill is shorn from the sheep and packed tight for shipping. Carding takes the wool and aligns the fibers in a single direction so that it can be twisted into yarns. American mills use Davis and Furber machines from the 1920s.

Wool cards align the wool fibers into a single direction

Spinning

Yarn spinning frame

Wool comes out of the card as loose strands that aren’t strong enough. They need to be rolled up, and put on a spinning frame, which twists them into yarns.

Weaving

A loom weaving wool cloth for blankets

The entire warp is moved onto a loom where thousands of threads are hooked up individually. They are run through and the weft is woven into them. The weaving can’t be too fast or the blankets won’t be soft enough. Each loom can only make a certain number of feet per day in order to maintain the right tension.

Napping

The napping department

One of the most important steps in the process is raising or napping the surface of the wool fabric. This gives it the soft, wooly surface that is a hallmark of a Chatham Blanket.

Finishing

The blankets are cut, and bound with a whipstitch. The final touch is sewing on the Chatham Blanket label.

Sewing a label on a wool blanket

Special Thanks

Jason Couch

Jon Dillon

John Litschke

Martha Smith

The town of Elkin

Chatham Family Members