A wonderful pair of scissors which uses a large symbol of Japan, the Cherry Blossom for its design

Wholly made in Japan, the Zanmai Sakura Scissors are a high quality multipurpose scissors which were born from the amazing skills of craftsmen from the cutlery crafting capital of Japan, Seki City. With multipurpose in mind and a cutting ability to match any other high quality pair of scissors, these are a brilliant pair of scissors to have in your kitchen drawers. We highly recommend you to give them a try!

The Zanmai Sakura Scissors are a pair of scissors that are exquisitely made, with functionality above and beyond that of a normal pair of scissors on the market.

From the steel used in their creation to the shipping, everything is Japanese.

The main idea behind creating the scissors was first and foremost the creation of a pair of scissors that was outstanding when it came to cutting ability, as when it comes to Kitchen utensils like this, cutting ability is much higher than other functions. In order to create such a cutting power, the most important part of making the blades is the tempering in fire.

A large 400t hydraulic press is used to push the base of the scissors out after they have been laser cut into the metal. What makes our scissors cutting ability different to others is the work we put into tempering the material. If we leave this process out, the scissors have a chance to not cut as well, or to bend, or to rust affecting the longevity of the scissors. We want to create an item that is perfect each and every time. This is why you can find a variety of cheaper scissors, because this important process isn’t done.

Please take a look at the images.

We hope that you try the Zanmai Sakura Scissors out!

We think you will be exceedingly satisfied with the results!

Like we said before, cutting ability is extremely important. It’s why we choose to use the amazing steel that is created in Japan. You can test this out with other cutlery that you have. The cutting ability of the Zanmai Sakura Scissors is so good that even times where you think to use a knife, you can use the scissors instead! Please give it a go!

Each process of making the scissors needs a specialist piece of machinery.

When using machinery isn’t possible to get the perfect sharpness, it comes down to the skills of the sharpener themselves. This in itself takes a while to do.

How the edge of the scissors are prepared

A craftsman works on an individual pair of scissors.

※The above is a video of knives being tempered by a machine, but the same process is followed for the scissor blades.

※The fires that temper the blades are about 200-215°C. It takes about 4 hours to temper the blades. This allows the scissors to gain flexibility to part of the blades, which means that they are able to cut anything from soft things to hard objects.

A never before seen original pair of scissors

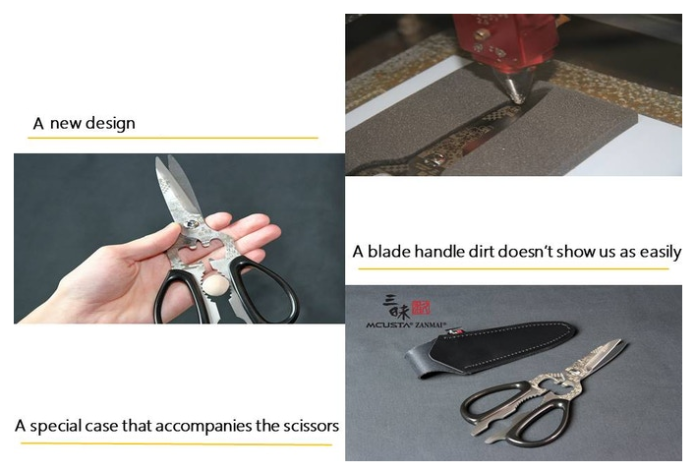

This time we have created a new design!

The design of the scissors are based on the science of ergonomics, and are a delight to use. They are of course multipurpose, and even if you use for a long time, they will feel natural and fit perfectly.

Even when you aren’t using them, they are aesthetically pleasing and look great to have in the kitchen.

They have been designed to use a sakura motif, one of the biggest symbols of Japan.

The Zanmai Sakura Scissors have their basis in swords, namely katana.

Katana are beautifully made, with a wonderfully aesthetic curvature.

As well as this, the design and cutting ability of Japanese swords are also legendary.

This pair of scissors is the result of all our hard work and dedication, as well as the skill of the craftsmen that work on them. The amazing skills and traditional craft that has been handed down over many many years combined with new technology has created what we think is a beautiful pair of scissors. When it comes to creating Japanese food, scissors can be an indispensable utensil in the kitchen, and are also useful when making other foods from different cultures. As well as this, they can find their roots in traditional Japanese swords.

Even today, there are many various swordsmiths in Japan, and the traditional sword craft is still alive even today. We are proud to say that we are based in Seki City, a city that has been at the heart of cutlery and sword making for over 800 years! Be it a great pair of scissors or beautiful katana, the skills to make the beauty and cutting ability are carrying on, and using the skills from the past we look to make newer better items for the future.

Found on the face of the scissors are a symbol of Japan, the cherry blossom or Sakura in Japanese. In the language of flowers, cherry blossoms as a whole are thought of as portraying moral beauty, or graceful femininity, and this is not only when they flower, but also when they fall and dance gracefully in the spring breeze. They are recognised as a Natural monument of Japan, and from Okinawa to the Tohoku region, there are over 39 different recognised species such as the Oshima zakura.

The serrated blade edge helps to cut into various types of food. For example slippery food such as kombu (edible kelp) or crab, the minute serrations help to get a grip on them. You can also use it on plastic packages and so on to cut with ease. This serrated edge is extremely useful in a variety of situations.

Making of the serrated edge

In the middle of the scissors, is a special opening that fits a bottle perfectly. The demand for bottle openers has seen a decline, but this is here for when you need them. You can also use this opening to hang the scissors.

In between the handle is a special nut cracker that is made to be easy to use. By putting the nuts in the middle and just closing the handle like you would when you are snipping away at something, the jagged edges bite into the nut making it open easily.

For the times where you can’t get your nails under that can lid, you can use this to slip beneath the hook and get some leverage on it.

As the handle is heat resistant you can wash the scissors in a washing machine without worry. Just separate them and then put them securely in the washer. You can also use them outside when camping! They’re great for when you want to cut things over an open fire.

By widely opening the scissors you are able to unhinge them and separate them. This is helpful when you want to clean them thoroughly or wish to put them into a dishwasher to clean.

They are also super easy to put back together, just by clicking them into place.

A town that holds over 50% of the market share of all Japanese made cutlery!

Seki City, Gifu Prefecture, is known as the cutlery capital of Japan, with over 50% of all the domestic market share of cutlery. It is also becoming known overseas as well, thanks to the high quality cutlery made in the area. Cutlery, especially knives, are popular among well known chefs, with them praising the quality of the knives.

The beginnings of this influence on cutlery began long ago, when Gifu prefecture was known as Mino Province, and two sword smiths, Motoshige and Kaneshige, came to the area, and created one of the 5 methods of sword craft or GOKADEN. From the end of the Heian Period (794-1185), the demand for swords for Samurai exploded. Swordsmiths in different regions of Japan used one of the five methods to create these swords, Yamato Den (Nara Prefecture)[大和伝(奈良県)], Yamashiro Den (Kyoto Prefecture) [山城伝(京都)], Bizen Den (Okayama Prefecture)[備前伝(岡山)], Sagami Den (Kanagawa Prefecture) [相州伝(神奈川)], and finally Mino Den (Gifu Prefecture)[美濃伝(岐阜)]. This reason that Mino Den was created was due to the amazing soil found in the area, the abundance of charcoal, and the brilliant quality of the water that ran through the area via the Nagara River, all parts that help to make an amazing sword. From the Maromachi Era and onwards, (1336-1573) more than 300 swordsmiths were born in the area, and after making a variety of amazing blades, and the diligent efforts and skills of the swordsmiths evaluated, Seki City Blades came to be known as [blades that done break or bend, and cut through anything].

Mino (Now Seki City) was home to one of the most famous bladesmiths known, Kanesada (Izuminokami Kanesada) who made some of Japan’s most famous blades. Their blades were known for being extraordinarily sharp. During the Edo Period, a book published mentioned his blade as being the highest quality sword made, alongside that of Magoroku Kanemoto another famous swordsmith.

When it comes to Japanese swords, they are evaluated on their cutting ability, with it being classed as WAZAMONO. From the top you have SAIJOUOOWAZAMONO, then OOWAZAMONO, then YOKIWAZAMONO, and then finally WAZAMONO. Both swords were ranked as SAIJOUOOWAZAMONO.

The blades that were made by the Magoroku Kanemoto, the cutting ability along with the ease of use for the blades were highly praised by various bushou (military commanders), among them, Hosokawa Tadaoki, Takeda Nobutora (Father of Takeda Shingen),Shibata Katsuie,and Akechi Mitsuhide. Without a doubt when it comes to weapons, the swords made by the 2nd generation Kanesada are of the highest quality.

We are able to include a picture of the most famous of the SAIJOUOOWAZAMONO blades with special permission from Seki City below.

①Blanking (Laser) | Cutting the shape of the blade out with laser

②Drilling | Removing the blade from the metal

③Tempering

④Finishing the outer face | Putting a satin finish on it

⑤Grinding the back face | One of the most important parts of making scissors. If not done properly it can have a large impact on the cutting ability of the scissors.

⑥Grinding the front face | The thickness of the edge of the blade is 0.5mm so this needs to be done in two stages

⑦Electrolysis | There’s no picture, but this is to help make the face of the blade less likely to rust

⑧Finishing the front face (Final finishing) | After the electrolysis, the satin finish needs to be redone

⑨Washing the blade | This is to get rid of the dust and dirt left on the blade.

⑩Finishing up | This is where we add the handle. We use an insert method, where the handle is directly applied to the blade.

⑪Grinding the edge | This is the final stage to bring the blade’s edge to 0.5mm.

⑫Serration | After bringing the edge to a finish the minute serrations are added.

⑬Adding the hinge | This lets you have a proper pair of scissors.

⑭Bending the scissors into shape | A craftsman bends the scissors into perfect shape, making sure each pair is perfectly aligned.

⑮Lasering | This adds the special design to the blade face.

⑯Maintenance | This is done twice to make sure the scissors are the best they can be. The edge is checked and oil and so on is wiped off the blade.

⑰Packaging | The finishing touch of adding the scissors to the box!

■ Material Used

NKS-215DT Stainless Steel 420J2 t = 3.0

(Sakura Custom) Blade: 420J2 STAINLESS STEEL

Hardness HRC-53 °

Handle: Culp resin

■ Size (specifications)

Overall length 215 mm, blade length 63 mm, weight 125 g

Marusho Co was founded around 56 years ago, namely as a cutlery producer.

At the time of founding, we were subcontracted to produce mixer blades, but under the current president, Mr. Hasegawa , we created the brand SILKY to create scissors.

Now we make Scissors (SILKY), Pocket Knives (MCUSTA), and Knives (Zanmai) as our three brands. Our design concepts focus on using machining to create precise and accurate items, combined with the skills of the amazing craftsmen that work with us.

We aim to be one of Japan’s foremost scissor makers!

Last year we worked with Seki City in a special collaboration.

せきてらす | せきのまど | 関市観光協会 (sekikanko.jp)

Kickstarter Project Launches: December 14th

Kickstarter Project Ends: January 28th 2022

Kickstarter Rewards Prepared: Feb- March 2022

Kickstarter Rewards Shipped: March 2022

InDemand Page Launches: May 2022

Rewards Arrive to Backers: June 2022